Steel roller cleaning device

A technology for cleaning devices and steel rollers, which is applied to cleaning devices for textile materials, printing, printing machines, etc. It can solve the problems of reduced service life of steel rollers, intensified corrosion, and inability to completely remove scale and rust residues, so as to improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

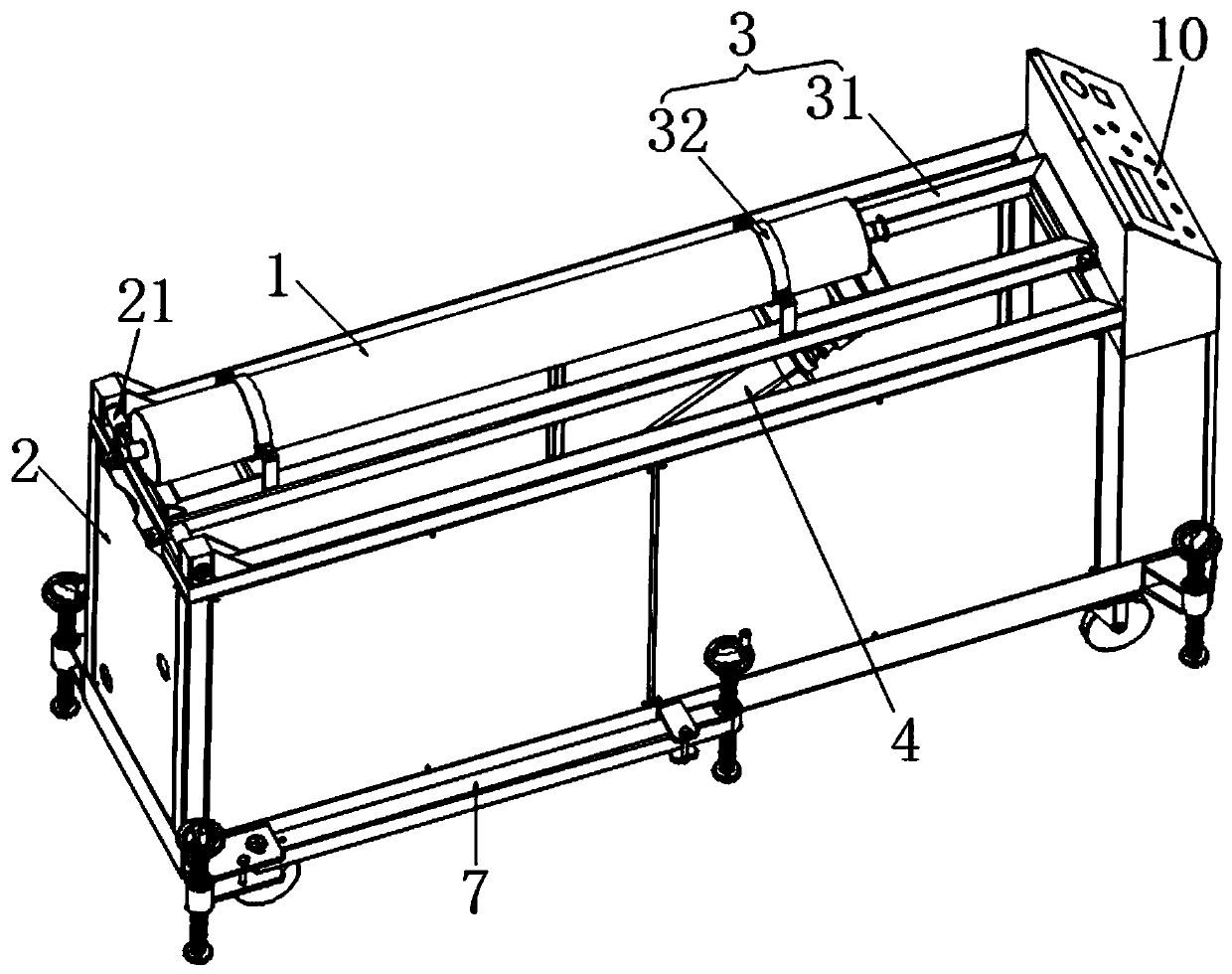

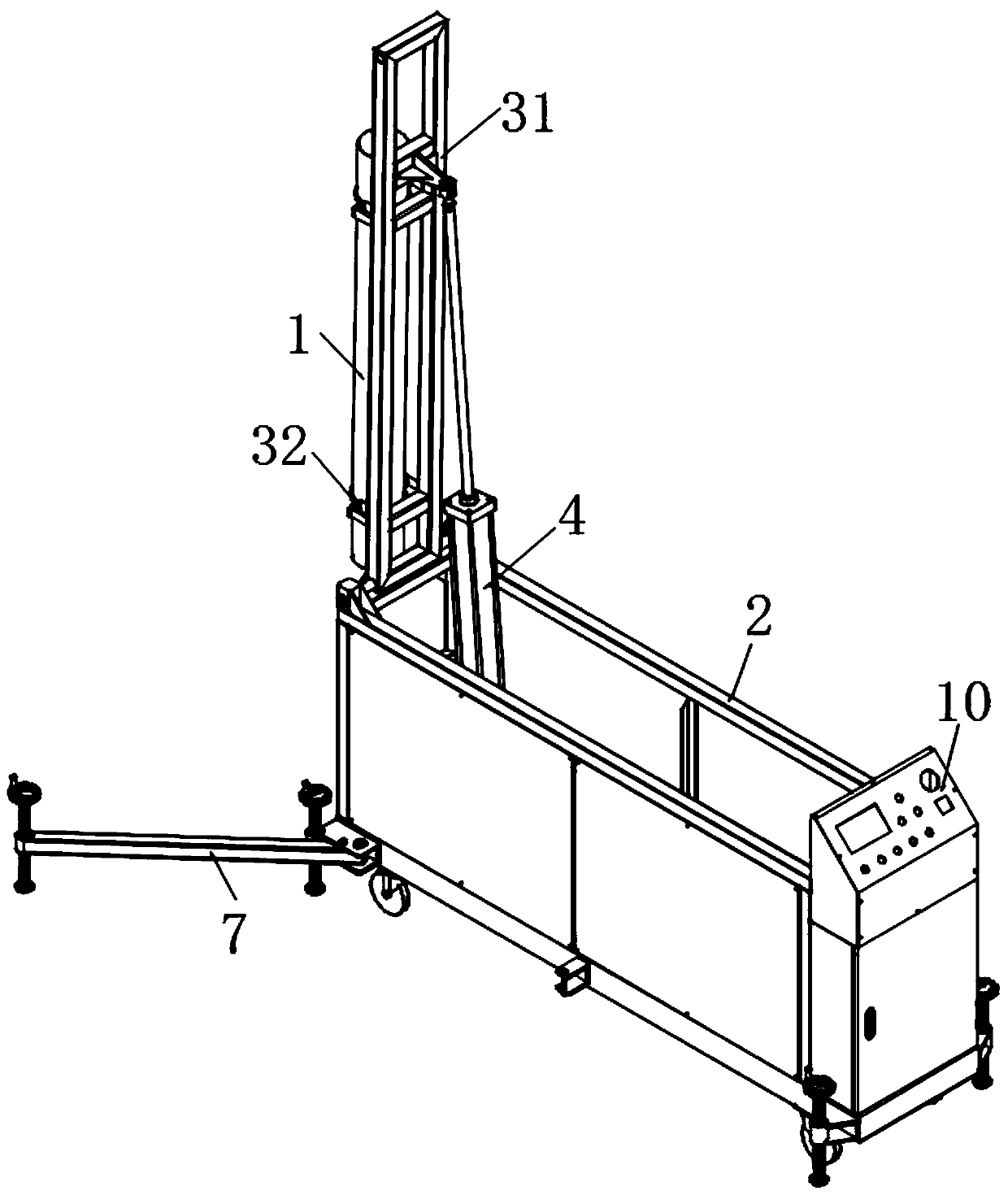

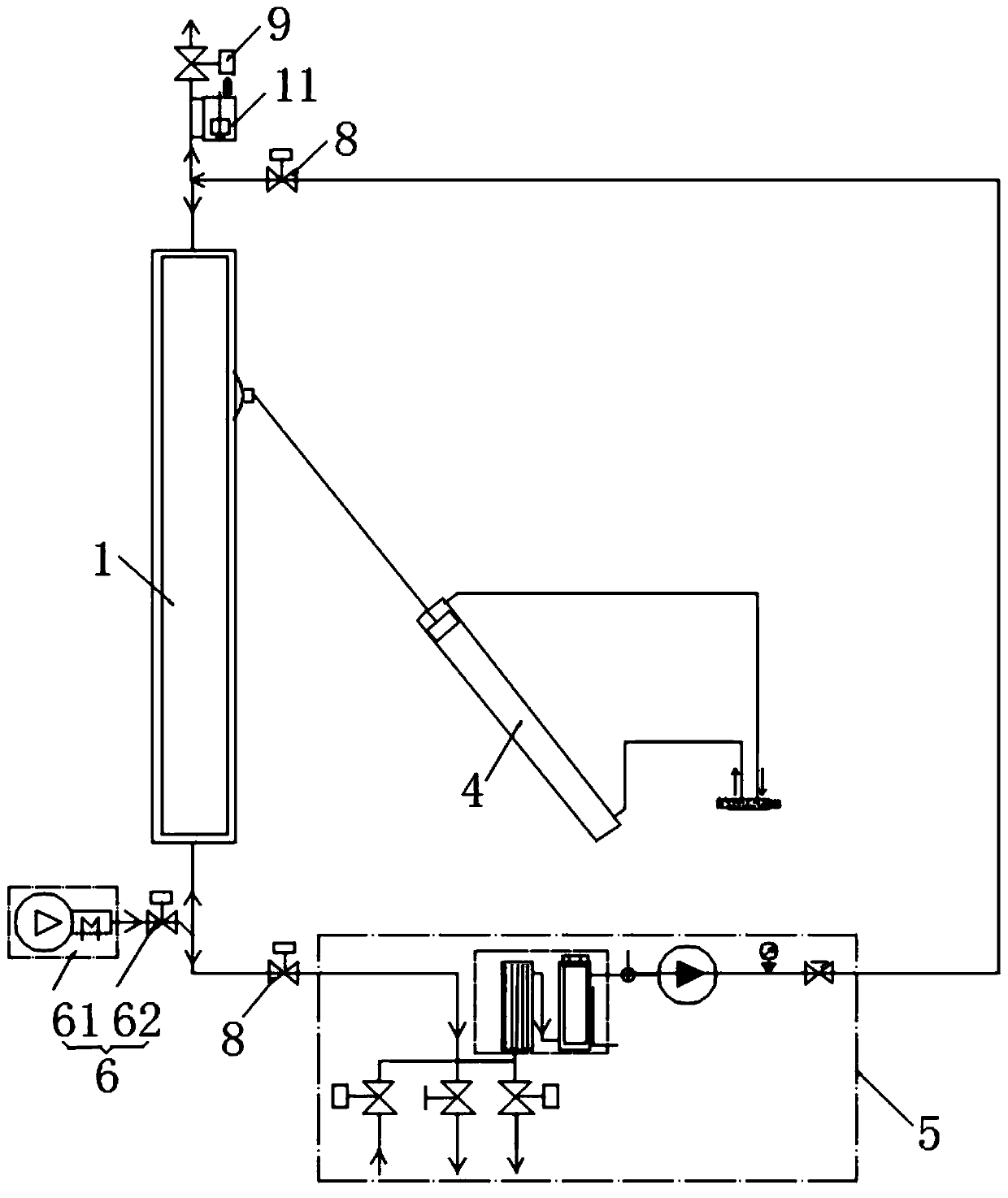

[0020] Such as Figure 1-3 As shown, a steel roller cleaning device includes: a frame 2, which is rotatably connected to the frame 2 and used to clamp the lifting mechanism 3 of the steel roller 1, and is used to drive the driving mechanism of the lifting mechanism 3 in a vertical state, for A circulating water washing system 5 for cleaning the steel roller 1 on the lifting mechanism 3 in a vertical state, and a drying mechanism 6 arranged at the bottom of the steel roller 1 for drying the cleaned steel roller 1 . When cleaning the steel roller 1, the driving mechanism drives the lifting mechanism 3 and the steel roller 1 to rotate upwards along the frame 2 to a vertical state, and the circulating water washing system 5 circulates the vertical steel roller 1 Cleaning, after the cleaning is completed, the drying mechanism 6 dries the clean...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap