A continuous icebreaker

An icebreaker, continuous method technology, applied in icebreakers, special purpose ships, ships, etc., can solve the problems of low icebreaking efficiency and damage to the hull structure, and achieve the effects of increasing breakability, reducing wear damage, and reducing lateral pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below by means of the accompanying drawings.

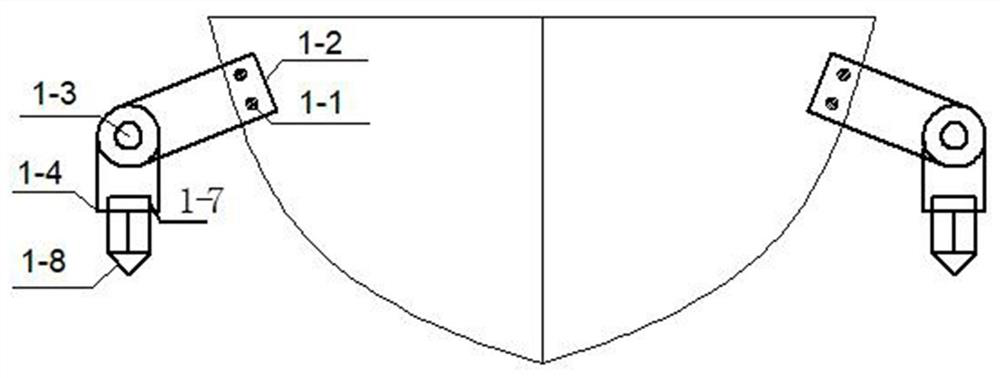

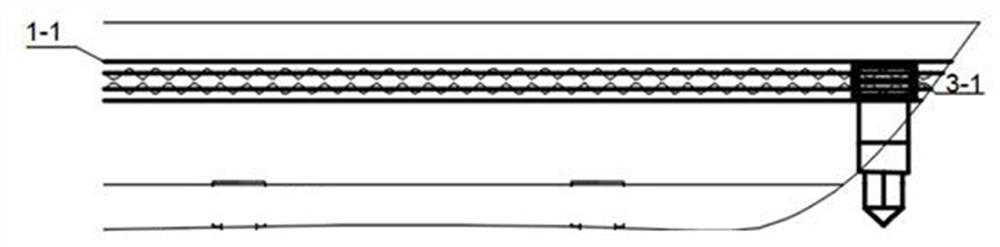

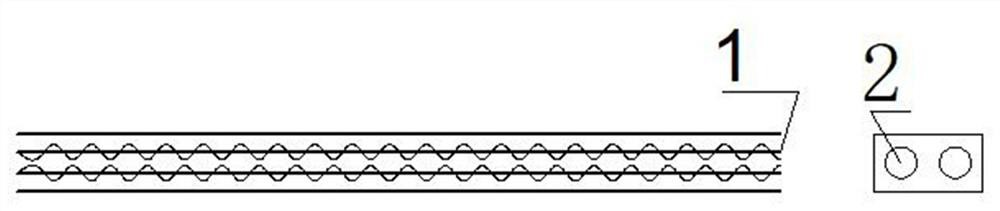

[0022] Such as figure 1 As shown, the invention provides an icebreaker for continuous icebreaking, including a hull, and an icebreaking device is respectively provided on both sides of the hull. , the second section mechanical support 1-4, the hydraulic starting device 1-7 and the cone head structure 1-8, the first section mechanical support 1-2 is arranged on the side of the hull, and the second section mechanical support 1-4 is connected with the mechanical support 1-2 at the first end through the shaft-coupling rotator 1-3, and the cone structure 1-8 is connected with the mechanical support 1-4 at the second section.

[0023] When the icebreaker is breaking ice continuously, the cone head structure 1-8 cones hit the ice floes on both sides to reduce the resistance it receives during navigation. When there is huge resistance during continuous ice breaking, the ice breaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com