Assembly of spinning equipment

A component and equipment technology, applied in textiles and papermaking, etc., can solve the problems of wear of traveler and ring, affecting yarn quality, short life, etc., to achieve the effect of reducing friction, avoiding collar slipping, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

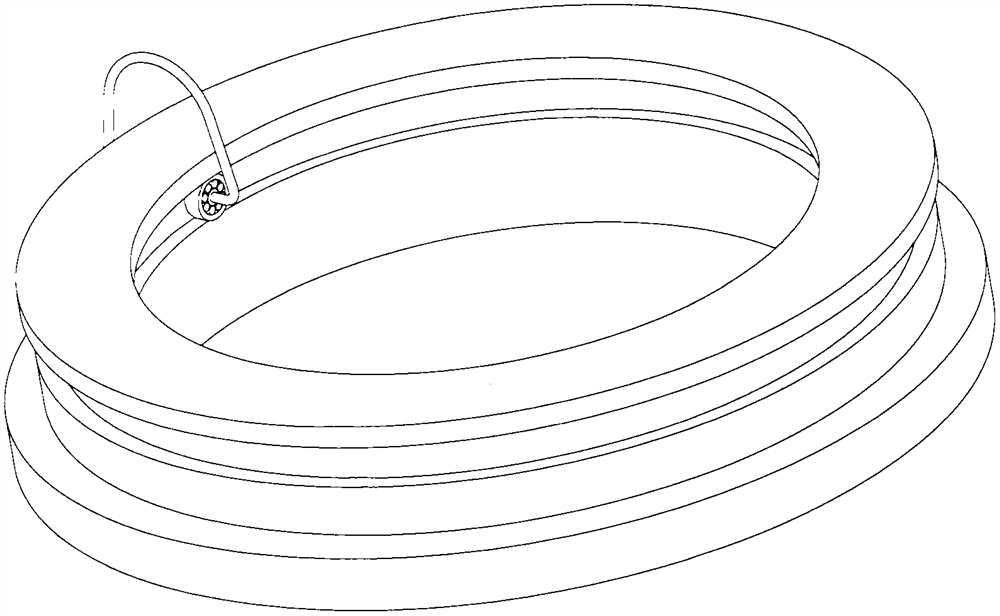

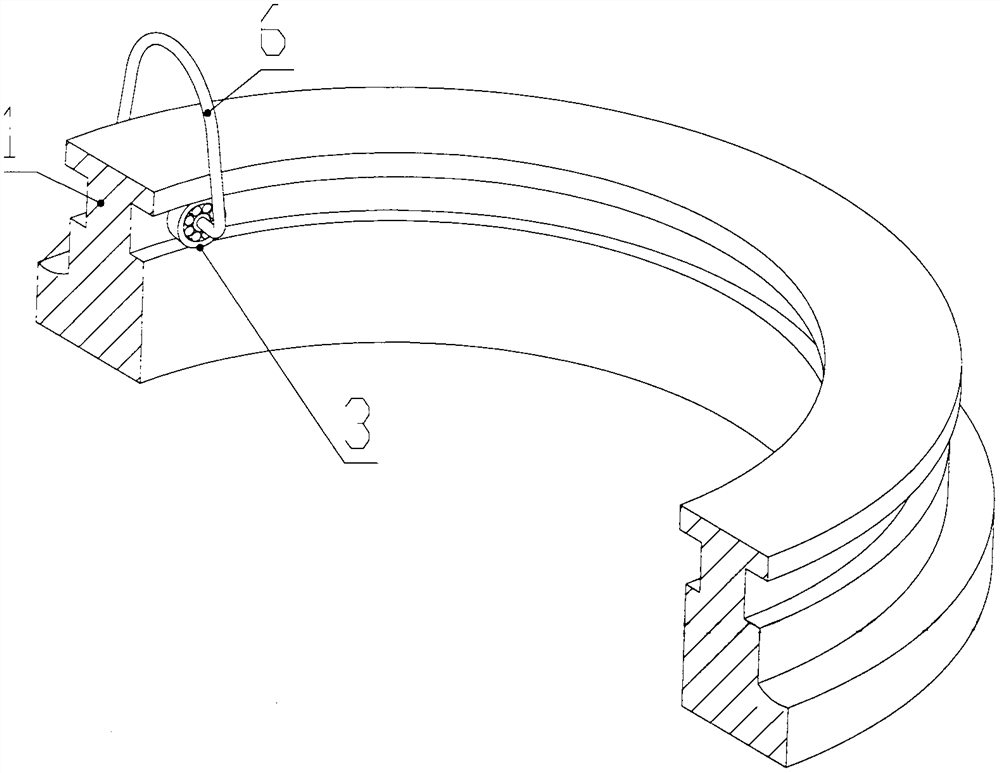

[0031] See attached figure 1 , 2 , the present embodiment adopts C-type or human-shaped traveler plus double bearings.

[0032] A component of spinning equipment, including a steel ring 1 and a traveler 6, the steel ring is in the shape of a ring, the traveler is a C-shaped traveler, and a bearing 3 is installed at the connection between the traveler and the steel ring, that is, at the end of the traveler. like Figure 8 , 9 , the two ends of the traveler are equipped with bearings, and the two bearings are coaxially opposite to each other; the steel ring is provided with a circular track 4 suitable for the bearing; the traveler is connected to the track through the bearings. When working, the traveler And the bearing slides along the track on the steel ring. It is also possible to add a special cover respectively in the middle of the c-shaped steel traveler two end bearings, and install a roller made of wear-resistant material on the convex top of the c-shaped steel trave...

Embodiment 2

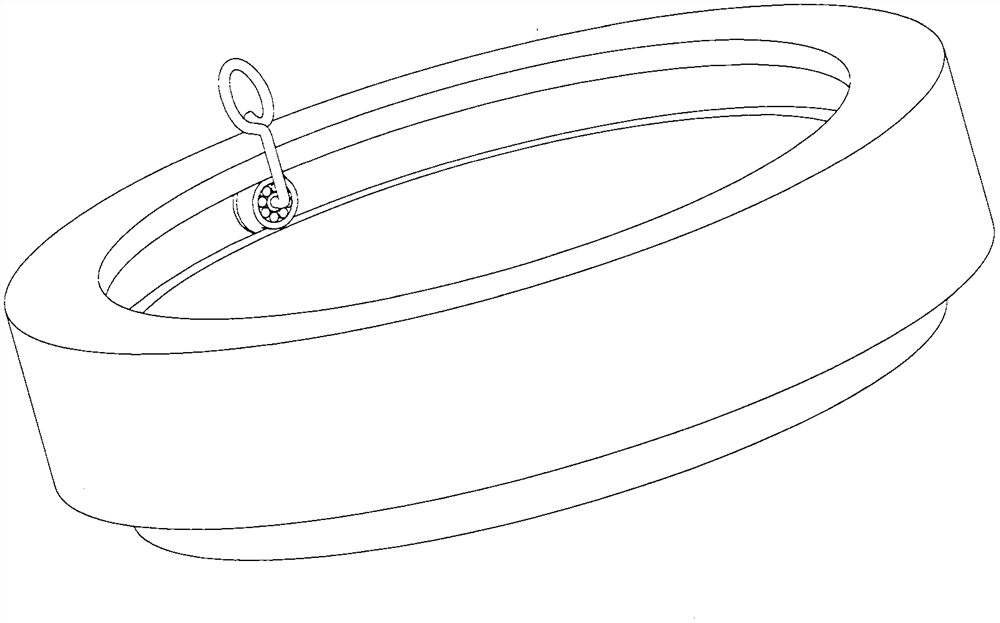

[0036] See attached image 3 , 4 , In this embodiment, an e-type steel traveler and a single bearing are used.

[0037] On the basis of Embodiment 1, in this embodiment, the steel ring is a split type, including the steel ring body 1 and the steel ring lower ring 2. The ring body and the steel ring lower ring are provided with grooves to form the bearing 3 and the wheel rim 31. Compatible circular track 4; such as Figure 10 , the traveler is an e-shaped pigtail wire hook, the upper part of the traveler 6 is helical and has an opening 61, the lower end of the traveler is equipped with a bearing, and the outer edge of the bearing is provided with a rim 31; insert the other end of the wire hook through a special sleeve The inner hole of the bearing is fixed, and the bearing is placed in the circular track. The ring body and the lower ring of the ring are fixedly connected by common methods such as buckle or screw.

[0038] The upper and lower circular track structure of sing...

Embodiment 3

[0041] See attached Figure 6 , 7 , 8, the present embodiment adopts parallel double g type pigtail steel wire to hook and add double bearing.

[0042] On the basis of Embodiment 2, in this embodiment, the traveler 6 adopts a parallel g-type pigtail wire hook, and the traveler is a parallel g-type pigtail wire hook whose tails are connected, and the two g-type pigtail wire hooks are in the same cylindrical surface Longitudinally juxtaposed; the upper part of the traveler 6 is helical and provided with an opening 61; the two g-shaped wire hooks adopt a left and right unscrewing structure; the double-folding and rotating bearing at the connection between the traveler and the steel ring; the lower ring of the steel ring is provided with a ring Cavity 21, the annular coil 7 is embedded in the annular cavity 21 of the lower ring of the steel collar, and the annular coil is equipped with a magnetizer ring 8 embedded in the annular cavity 21; the permanent magnet 9 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com