Textile technology

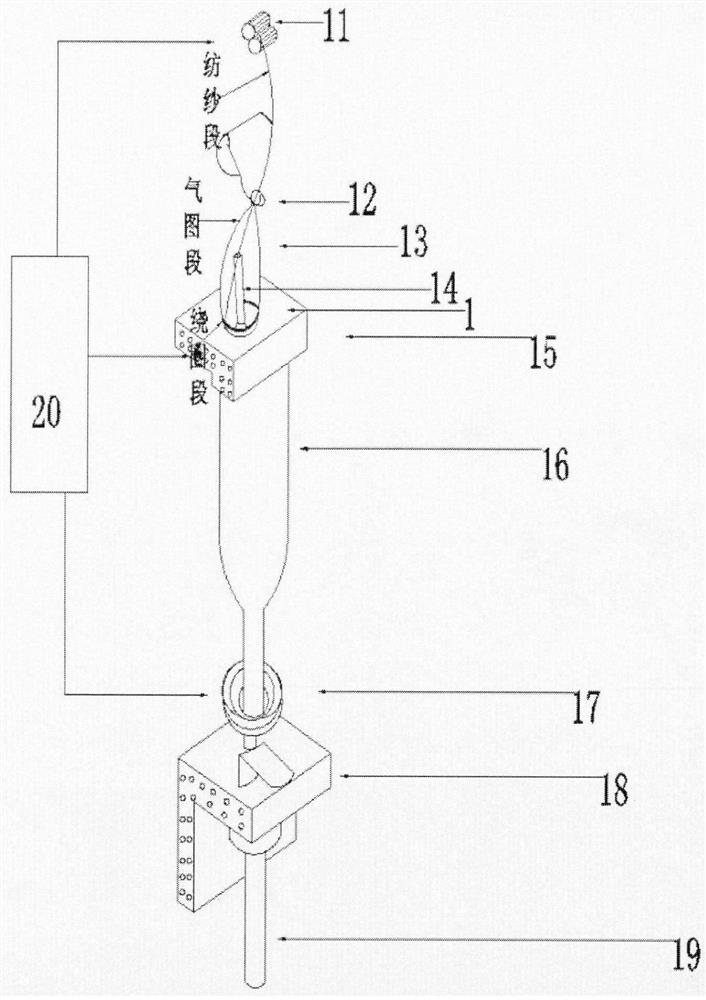

A technology, the technology of the traveler, which is applied in the direction of textiles and papermaking, can solve the problems of labor loss, increased power consumption, and delay in production, and achieve the effects of reducing equipment weight and cost, reducing friction, and avoiding collar loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

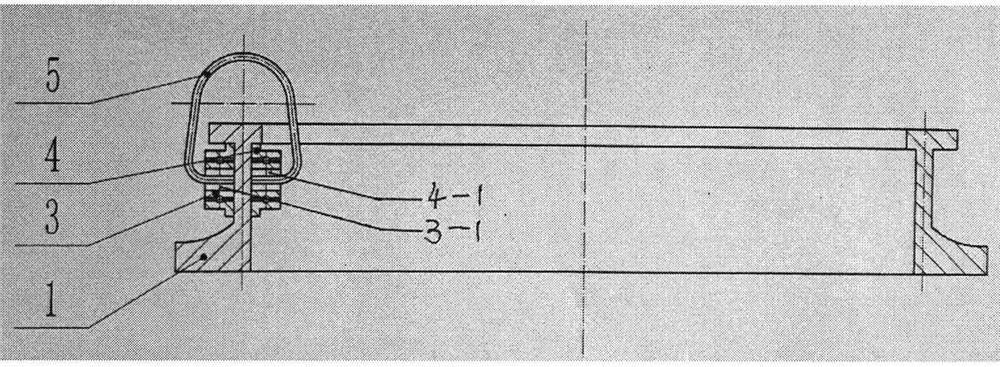

Embodiment 1

[0009] Both ends of the traveler adopt double bearings or use wear-resistant material wheel system, which is easy to modify, takes less time and has a longer service life. It is most suitable for the transformation of existing factories, and the existing steel ring is used. The traveler only needs to install the two ends of the original traveler. Wear-resistant material wheels or bearings are also available, but because the original steel wire (belt) ring is too small, it is inconvenient to install the wheel, so it is processed with steel wire, and the ring can be slightly longer to facilitate installation and threading, so that the steel traveler is really made of steel wire and round The century-old dream of the textile industry, light in weight, easy to process, and low in cost. The two ends of the c-shaped traveler are equipped with bearings and special sleeves are installed in the middle. The convex part can also be equipped with wear-resistant material rollers, and the rin...

Embodiment 2

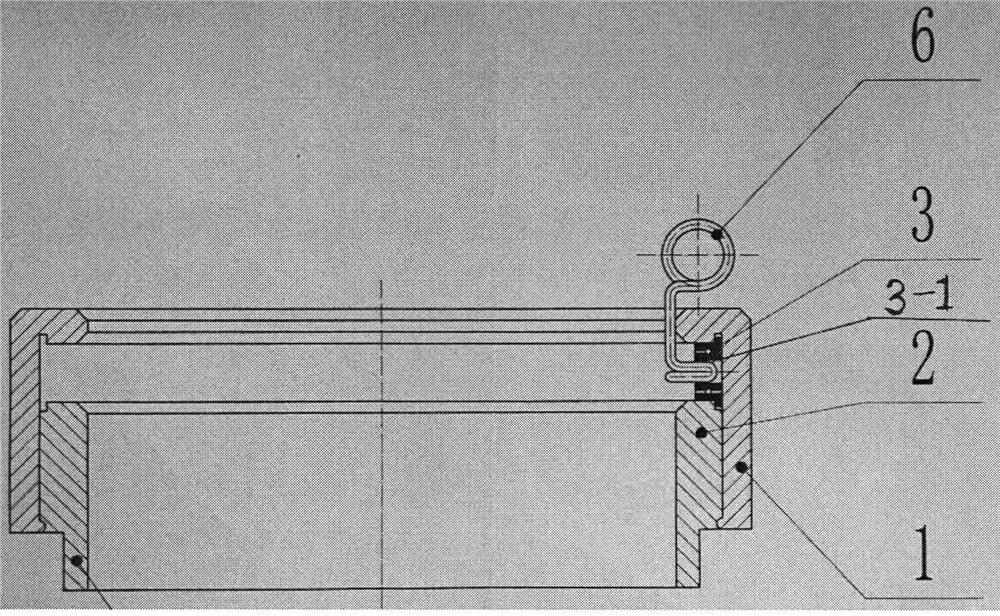

[0011] Due to the heavy weight and high cost of the double bearings, the threading efficiency of the closed yarn of the traveler is low, and the front roller cannot be stopped alone, and a lot of cotton yarn will be wasted if it cannot penetrate the traveler in time and quickly so that the yarn can be wound quickly. The single-bearing upper and lower circular track structure is adopted, and The lower track can be disassembled to reduce bearing cost and resistance design. The e-type open pigtail wire hook is adopted. The other end of the wire hook is inserted into the inner hole of the bearing through a special sleeve to fix it. At the same time, the steel ring is also modified accordingly, and the steel ring is appropriately increased. The inner diameter of the collar makes the single spindle more entangled and reduces the number of yarn changes. Corresponding to the inner side of the inner slideway of the original steel ring, a recessed groove is processed as the upper track of...

Embodiment 3

[0013] On the basis of the single bearing track, add a bearing in series before or after the original bearing, connect it with a g-shaped pigtail hook and install a permanent magnet (rotor) to realize electric and active wire hooks. Yarn hanging avoids the difficulty of the traveler moving when threading the yarn, and greatly improves the efficiency of the car operator. Since the traveler in Embodiment 1 and 2 is passive, it is not conducive to spinning worsted yarn. Twisting resistance limits the fineness of the spinnable yarn and line speed, so this embodiment is characterized in that the active traveler design is adopted, the electric traveler adopts a special structural design, the linear motor ring is made, the embedded shaftless motor is used, and high-frequency magnetic materials are used to make ( Rotor) rail car has reached high speed and low consumption. See image 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com