Automatic box packing equipment, sealing device and box cover pressing and folding mechanism of sealing device

A technology of box cover and positioning mechanism, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., and can solve problems such as no insertion rod provided, box tongue cannot be inserted correctly, and high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

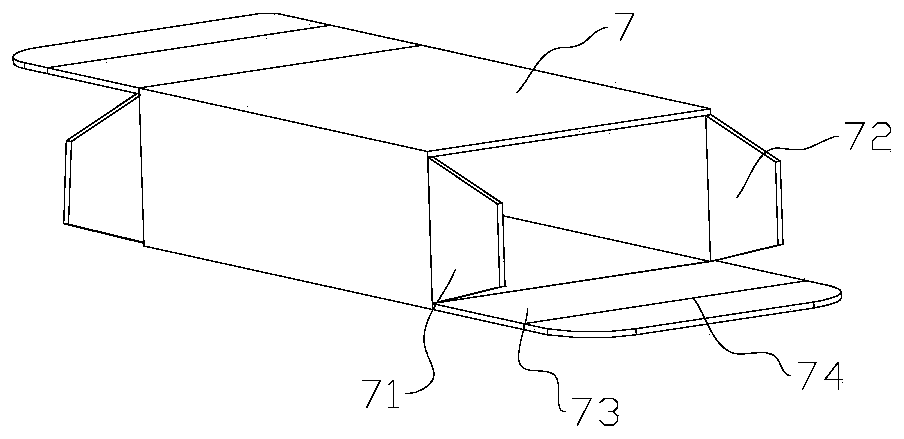

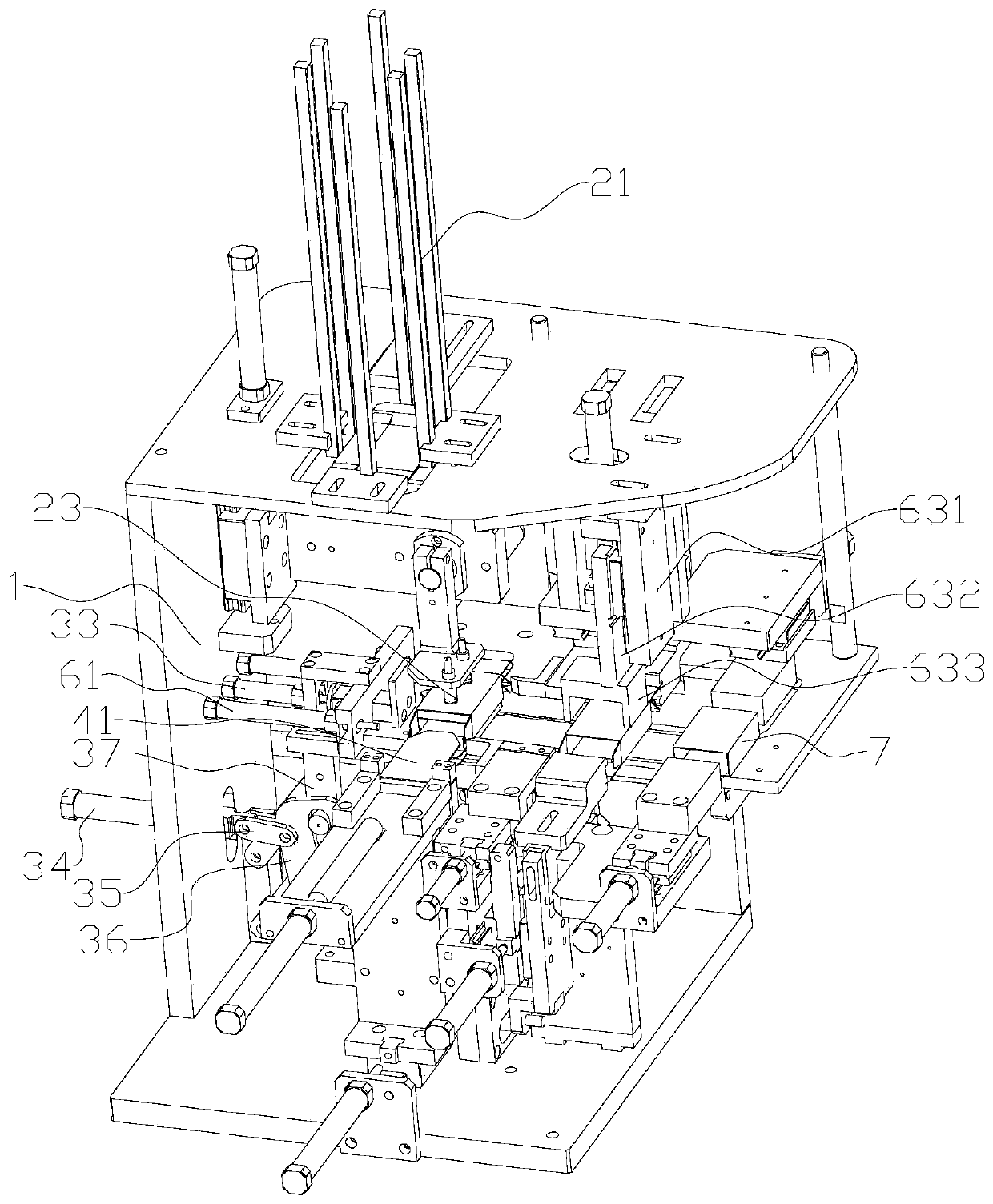

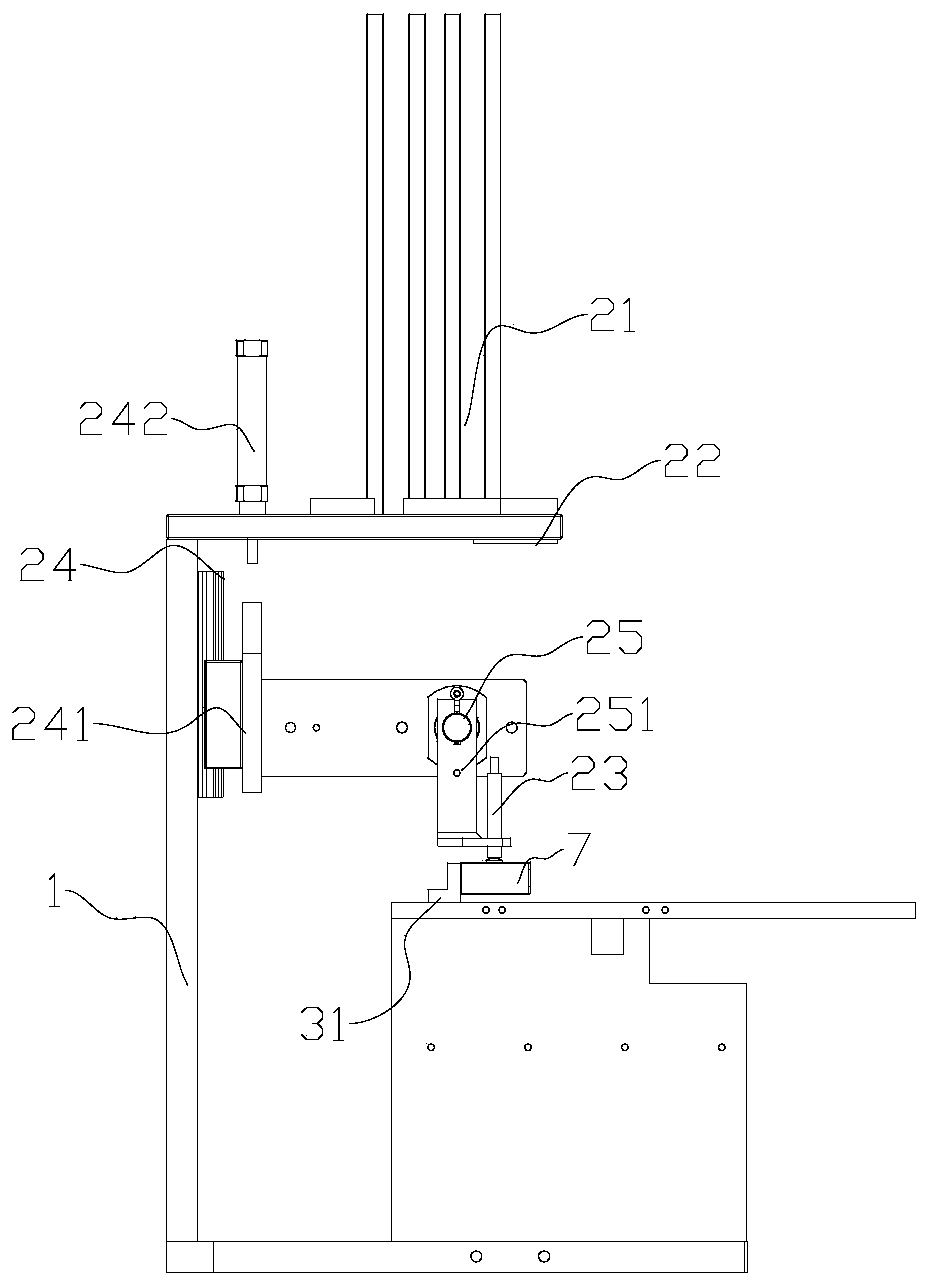

[0029] Such as Figure 2-8The shown automatic box-packing equipment includes a frame 1, and a carton pick-up device, a box-opening device, a box-filling device, a box-packing conveying device, and a sealing device that are sequentially arranged on the frame 1 along the processing sequence. The carton retrieving device is used to feed the carton in the flat state, and transports the carton to the box opening device, and the carton opening device is used to open the carton in the flat state to form a three-dimensional box body 7, The box loading device is used to send the workpiece into the three-dimensional box body 7, the box-packing conveying device is used to transport the three-dimensional box body along a specific track, and the sealing device is used to press the box cover into the box body 7.

[0030] The specific execution structure and movement steps of the carton retrieving device, box opening device, carton loading device, box packing conveying device and sealing dev...

Embodiment 2

[0062] The specific scheme of this embodiment is as Figure 9 As shown, the automatic box-packing equipment in this embodiment adopts a multi-station scheme on the frame (the description of this paragraph does not include the fine pressing station); in embodiment 1, the box opening station and the sealing work are included in the scheme Both the unpacking device and the packing device work on the unpacking station. In this scheme, a box-opening station, a box-packing station, front and rear wings are used for sealing, and a multi-station structure of the sealing station is adopted. Work on the box station. Through the above improvements, the box unpacking device and the box loading device can run synchronously without sequence, improving the working efficiency of the automatic box packing equipment. Therefore, the difference between the solution of this embodiment and the solution of Example 1 is only the change in the increase of the above-mentioned box-filling station, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap