Garbage can and dry-wet separation type garbage can

A dry and wet separation, trash can technology, applied in trash cans, garbage collection, waste collection and transfer, etc., can solve problems such as unsanitary and inconvenience, and achieve the effects of preventing rot, convenient operation and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Dry and wet garbage are stored together, and soaking for a long time will accelerate decay, produce peculiar smell, and easily breed bacteria. There are also dry and wet garbage stored separately in the existing trash cans, but no further treatment is carried out on the dry garbage and wet garbage, and the dry garbage and wet garbage are simply stored separately. Dry garbage generally includes paper scraps, fruit peels, etc. Light things are not easy to sink into the bucket automatically, and the part containing dry garbage will be full soon, requiring manual pressing, which is unhygienic and inconvenient; on the other hand, wet garbage contains water and cannot be disposed of in the garbage can If it is, it will also produce peculiar smell and breed bacteria.

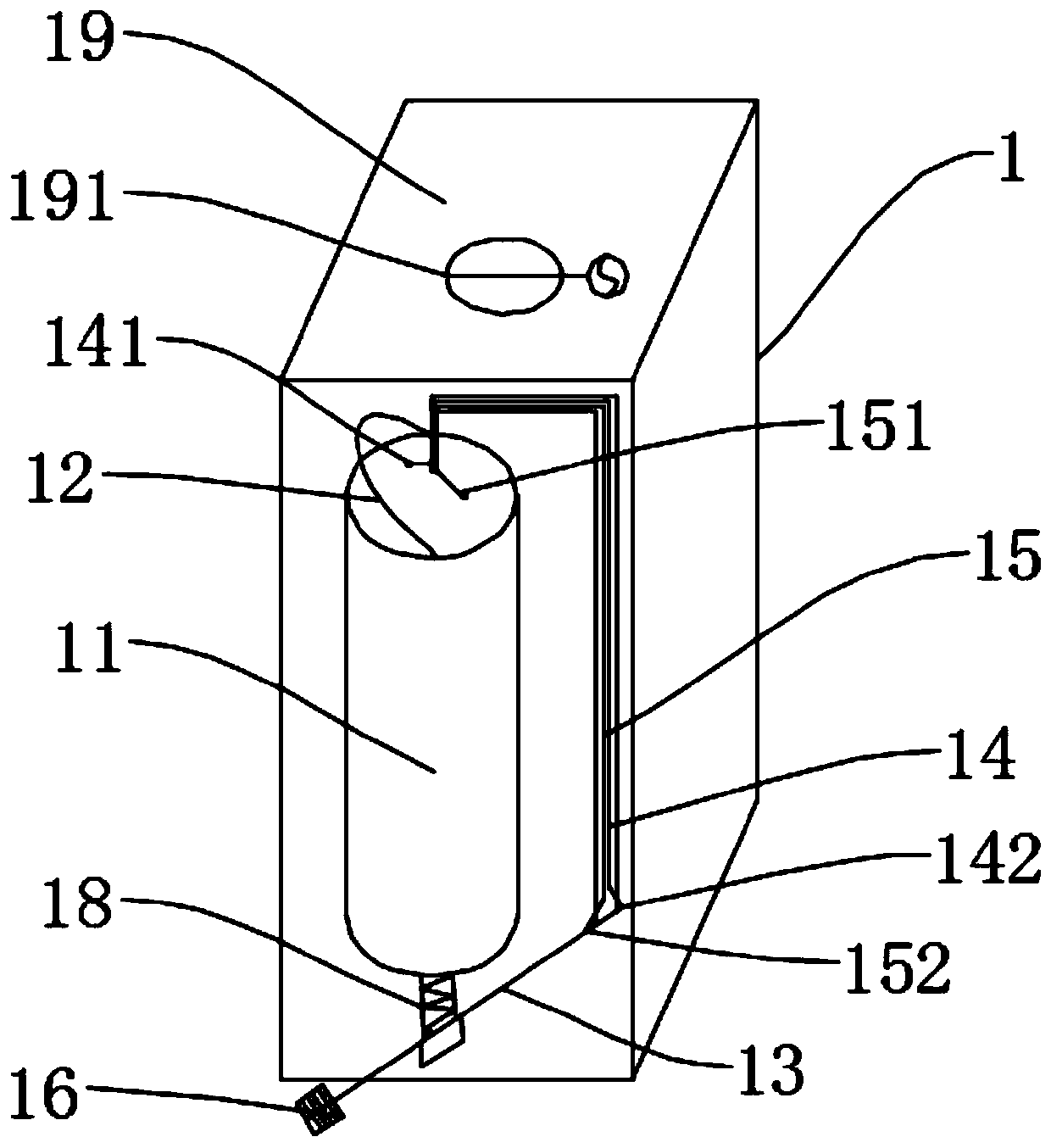

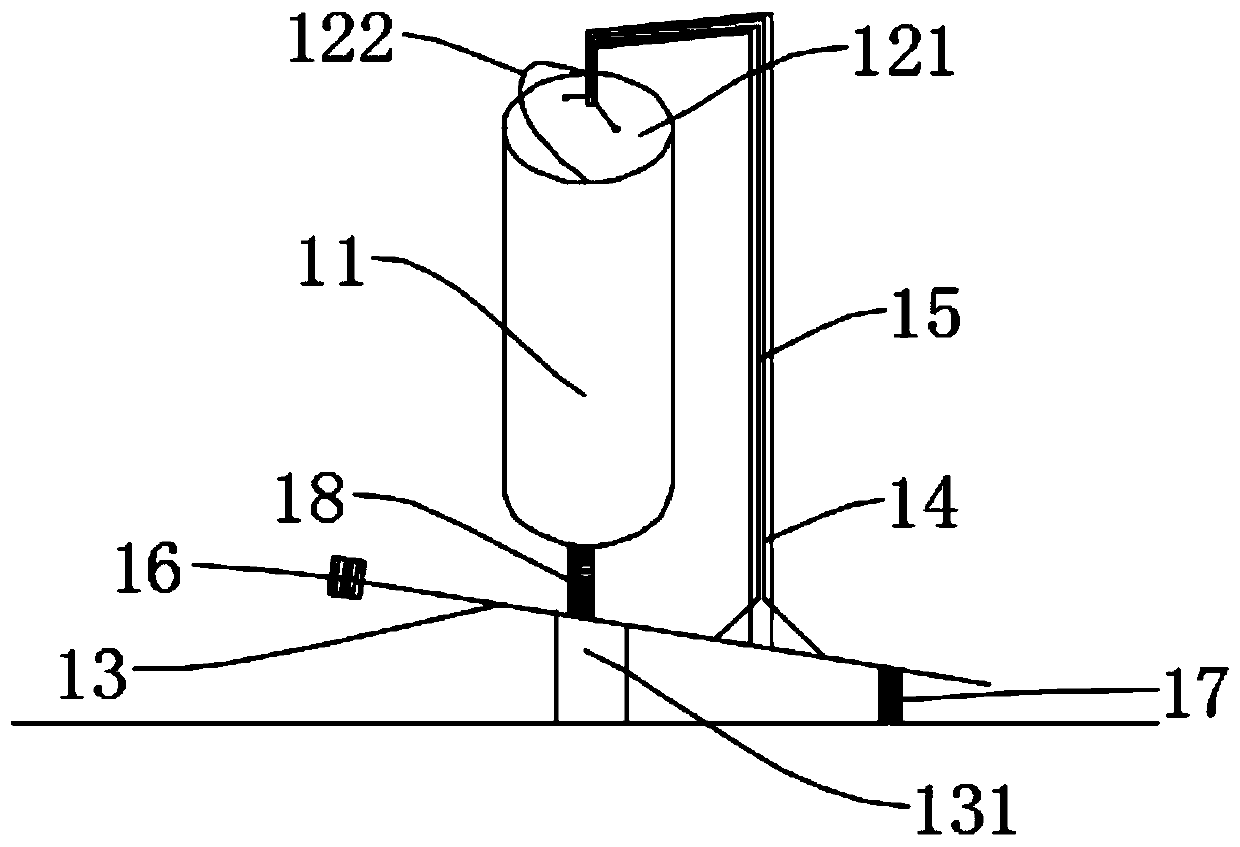

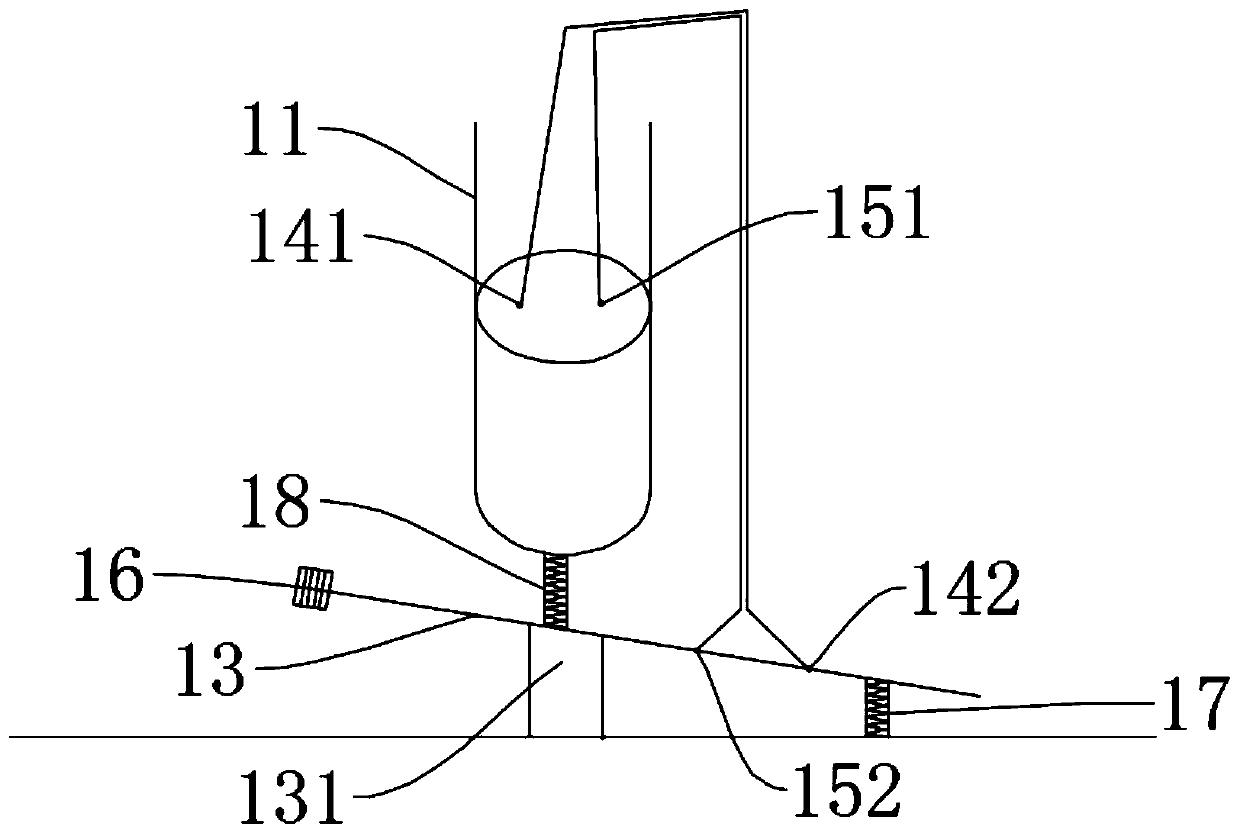

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com