Asphalt modifier, preparation method thereof and application in asphalt composition

An asphalt modifier and asphalt composition technology, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of high and low temperature performance, poor water damage resistance, unattainable warm mix asphalt pavement performance, and cost It can improve high temperature performance, reduce mixing and compaction temperature, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention provides, in a second aspect, a method for preparing polyethylene wax with a melting point of 70-120° C. The preparation method includes the following steps:

[0049] (1) Mix 2,6-diacetylpyridine and dichloromethane, add 4-methoxy-2-methylaniline under stirring, add dropwise formic acid, react under heating and reflux conditions, spin dry, to obtain the first product;

[0050] (2) the first product is mixed with anhydrous methanol, and the obtained solid is filtered, washed, and dried in vacuo to obtain the second product;

[0051] (3) the second product is mixed with ferrous chloride tetrahydrate, the mixed system is evacuated with argon, then tetrahydrofuran is added under stirring conditions, and the reaction is maintained under the positive pressure state of argon in the system, and the reaction product is protected by argon Under filtration, the obtained solid is washed and vacuum-dried to obtain a late transition metal catalyst;

[0052] (4...

Embodiment 1

[0064] Mix 0.5 g of 2,6-diacetylpyridine and 30 mL of dichloromethane, add 1.5 mol of 4-methoxy-2-methylaniline under stirring, add 3 drops of formic acid dropwise, and then heat the reaction system to make it The temperature is raised to 50-55° C., and the mixture is refluxed for 48-50 hours, and then spin-dried to obtain a wine-red oil, namely the first product.

[0065] The first product was mixed with frozen anhydrous methanol, and a yellow-green powder was precipitated at this time. The obtained solid powder was filtered, washed with frozen anhydrous methanol, and vacuum-dried at 60° C. to obtain the second product.

[0066] The second product is mixed with ferrous chloride tetrahydrate, and the molar ratio of the two is (1~1.05): 1. The mixed system is evacuated with argon gas, and then tetrahydrofuran is added under stirring condition, and the system maintains the argon gas positive pressure state. After 50-60 minutes of reaction, stop stirring, let stand for 10 minutes...

Embodiment 2

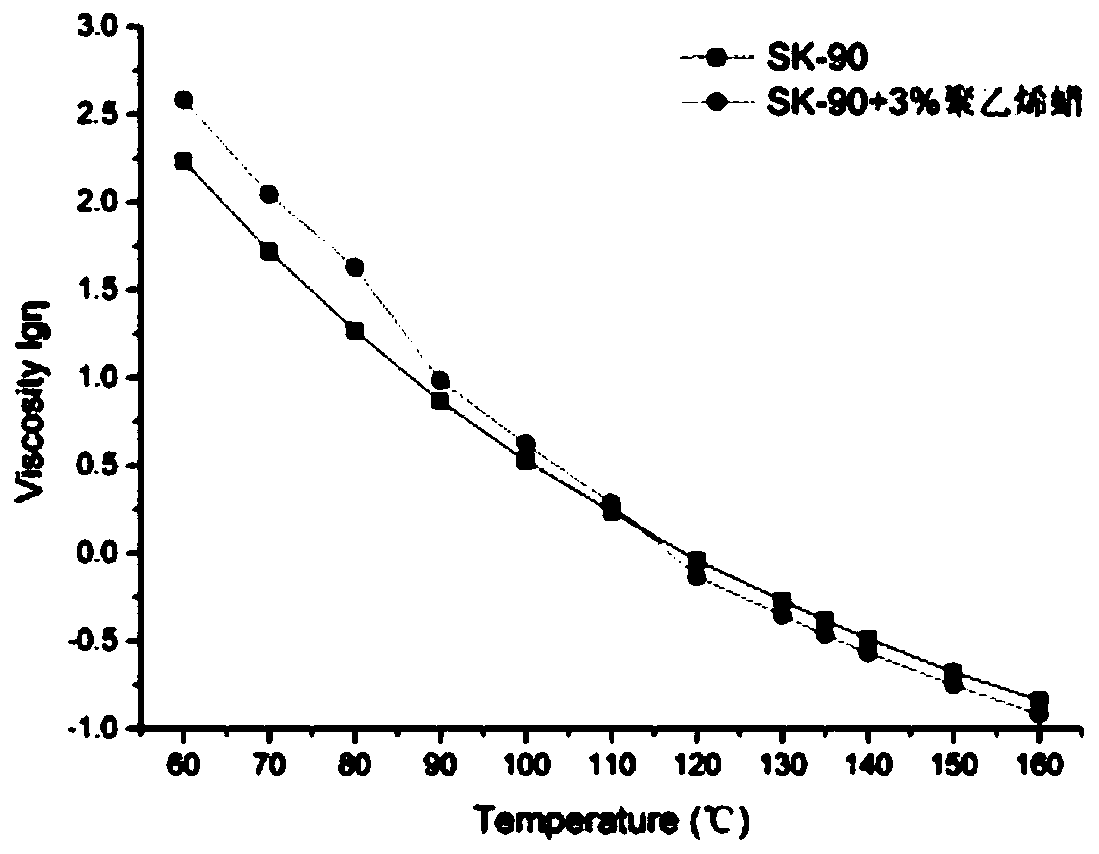

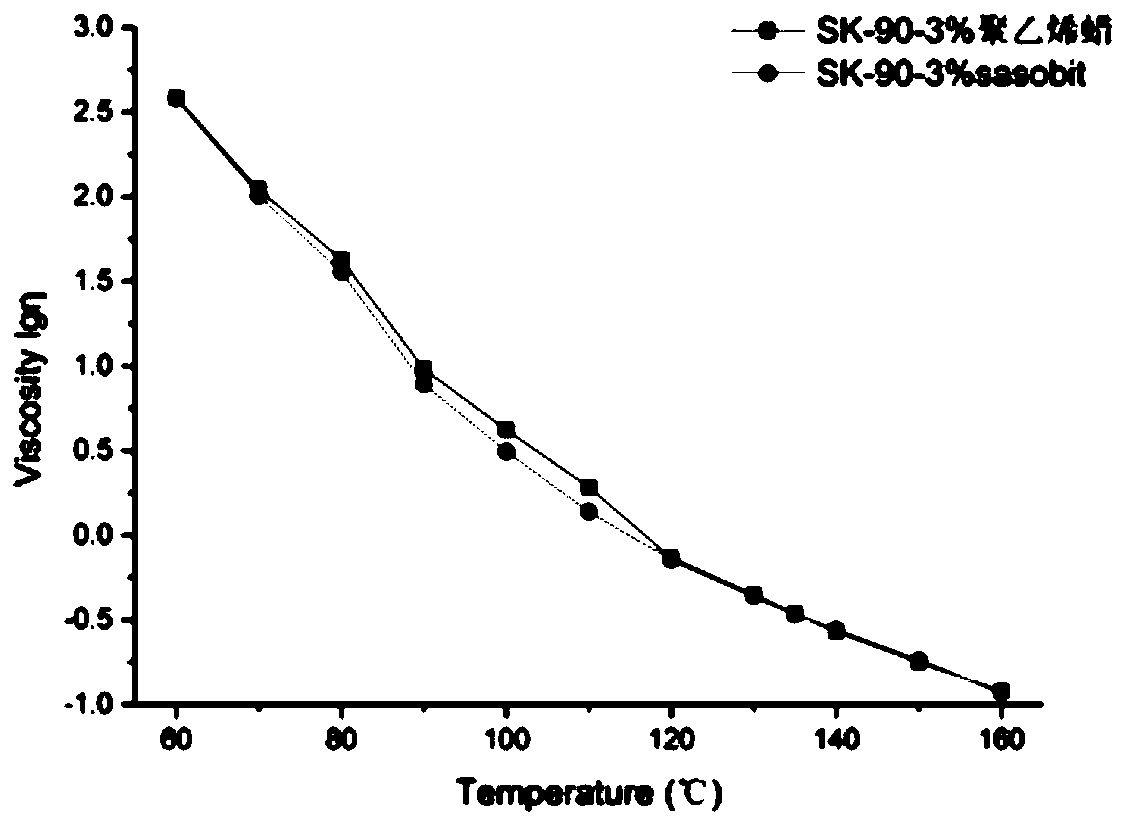

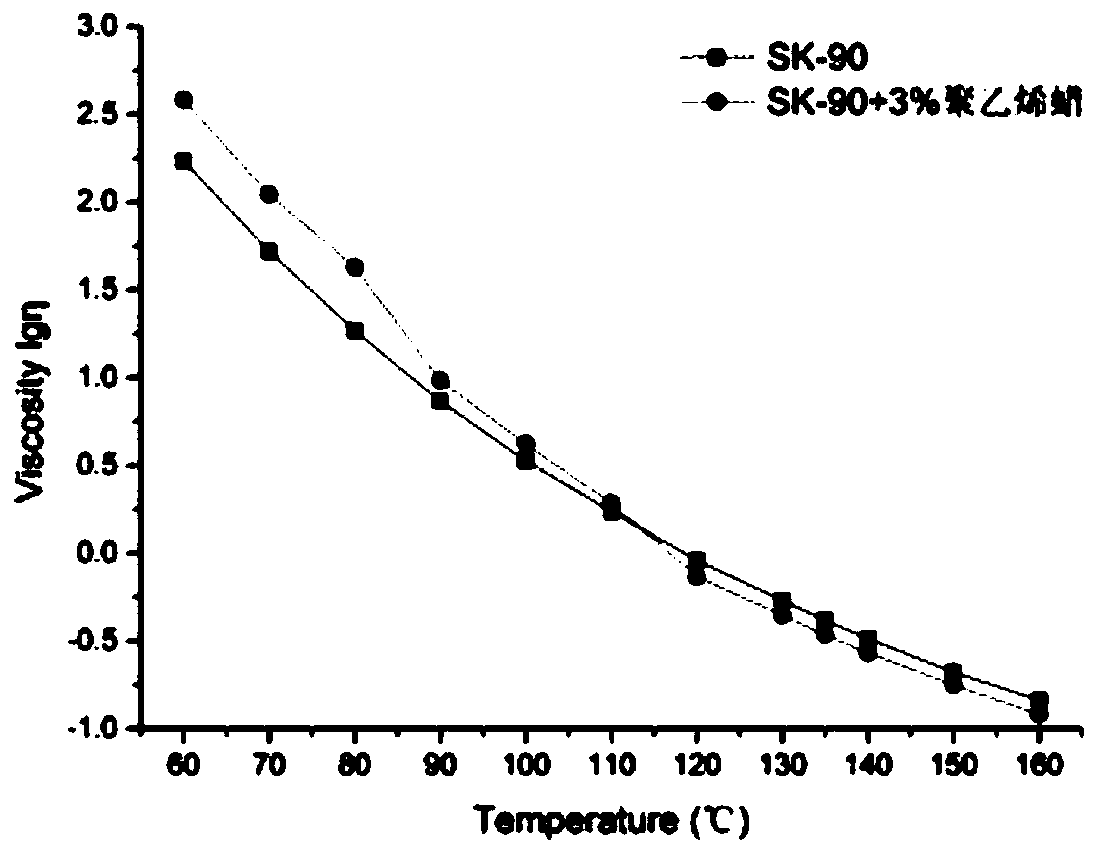

[0069] An asphalt composition comprising the polyethylene wax prepared in Example 1 and SK-90 base asphalt, wherein the mass percentage of polyethylene wax is 3%, and the balance is SK-90 base asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com