C-shaped steel hole plane connector

A technology of planar connection and C-shaped steel, which is applied in the direction of construction and building construction, etc., can solve the problems that the connectors cannot be connected, and there is no C-shaped steel head-to-head flush connection connector, etc., so as to achieve a firm and stable connection and not easy to bear force Deformation, connection safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

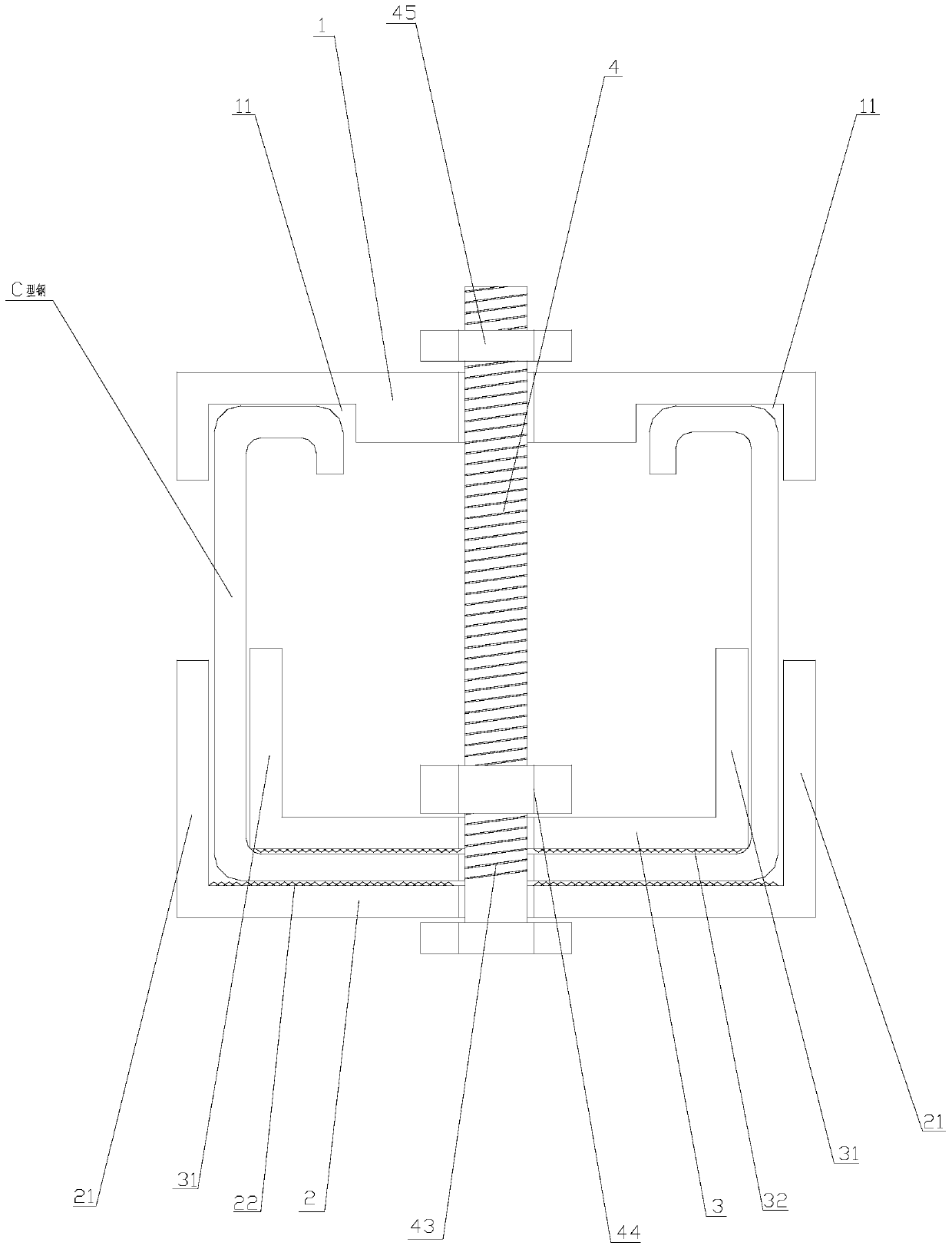

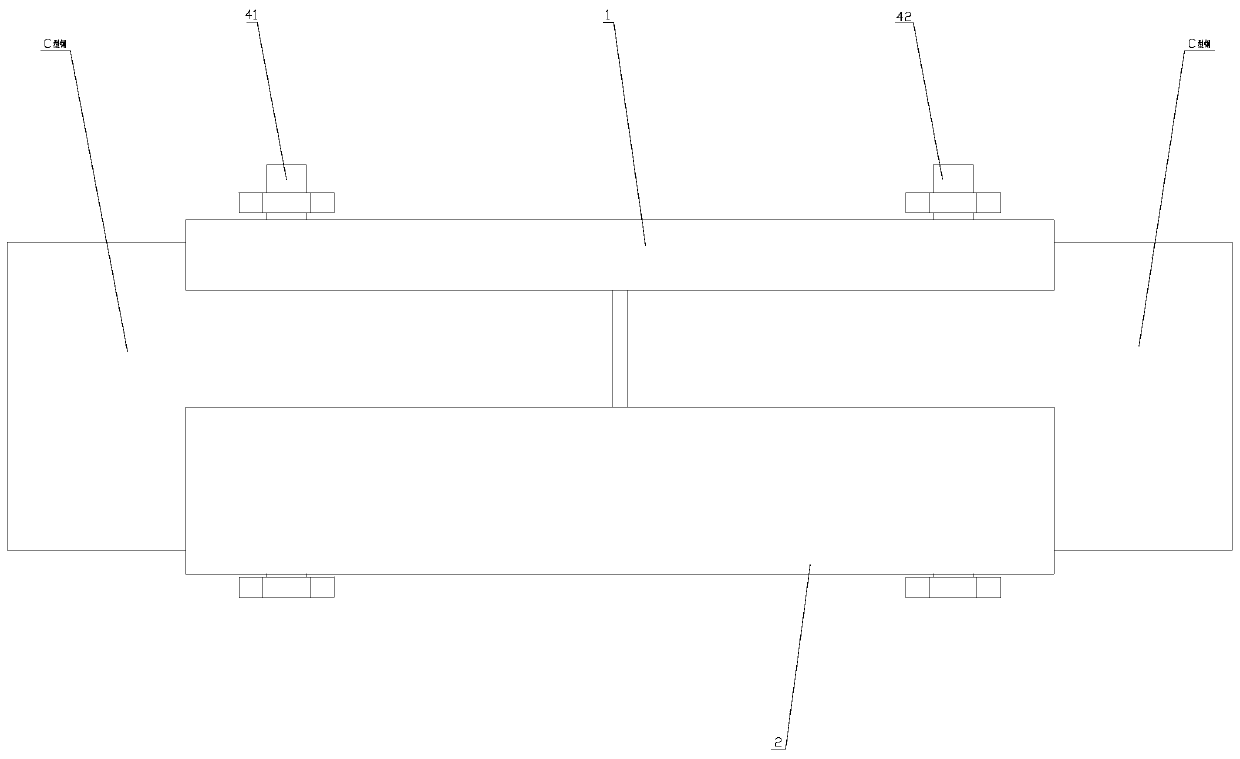

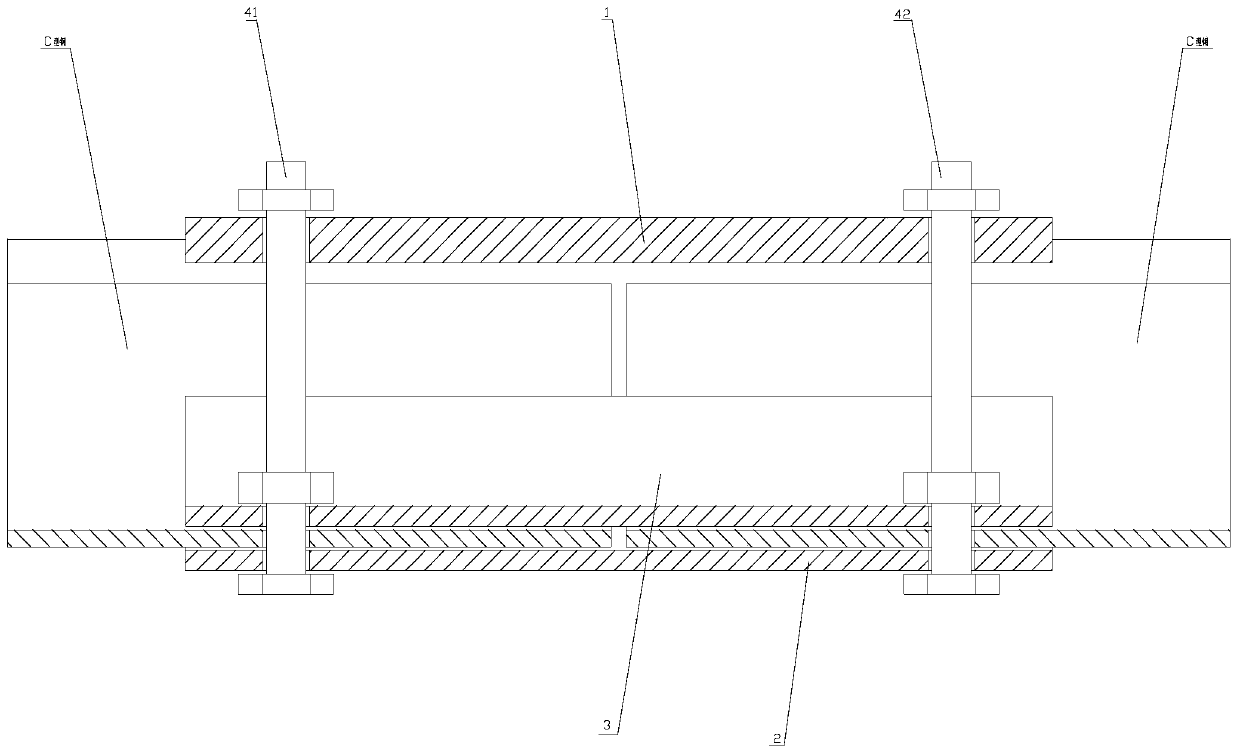

[0022] refer to figure 1 , figure 2 with image 3 , a C-shaped steel hole plane connector of the present invention, comprising an upper cover plate 1 of the connector, a lower bottom plate 2 of the connector, an inner connector 3, and a plurality of fixing bolts 4, the lower bottom plate 2 of the connector can be connected with the lower end surface of the C-shaped steel Cooperate, the upper end of the lower base plate 2 of the connector is provided with an inner connector 3 that can cooperate with the inner lower end surface of the C-shaped steel, and the upper end of the inner connector 3 is provided with an upper cover plate of the connector that can cooperate with the upper end surface of the C-shaped steel 1. The upper cover plate 1 of the connector, the lower bottom plate 2 of the connector, and the two ends of the inner connector 3 are fixedly connected to the C-shaped steel through the first fixing bolt 41 and the second fixing bolt 42 respectively, and the first fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap