Ceramic or purple sand electric ceramic stove

An electric ceramic stove and purple sand technology, applied in the field of electric ceramic stoves, can solve the problems of long-time cooling panel, heating heat dissipation, slow heating speed, etc., and achieve the effect of suppressing heat loss, improving heating speed and efficiency, and preventing thermal interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

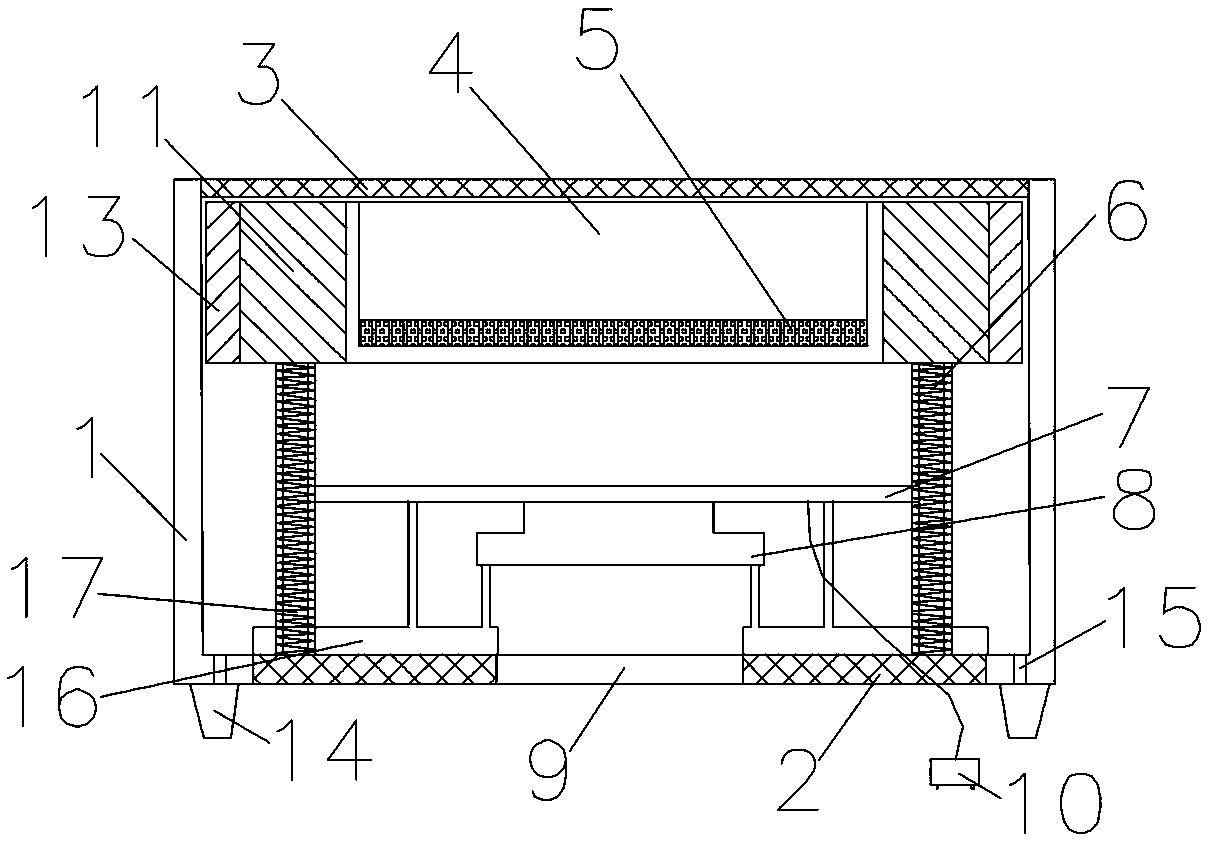

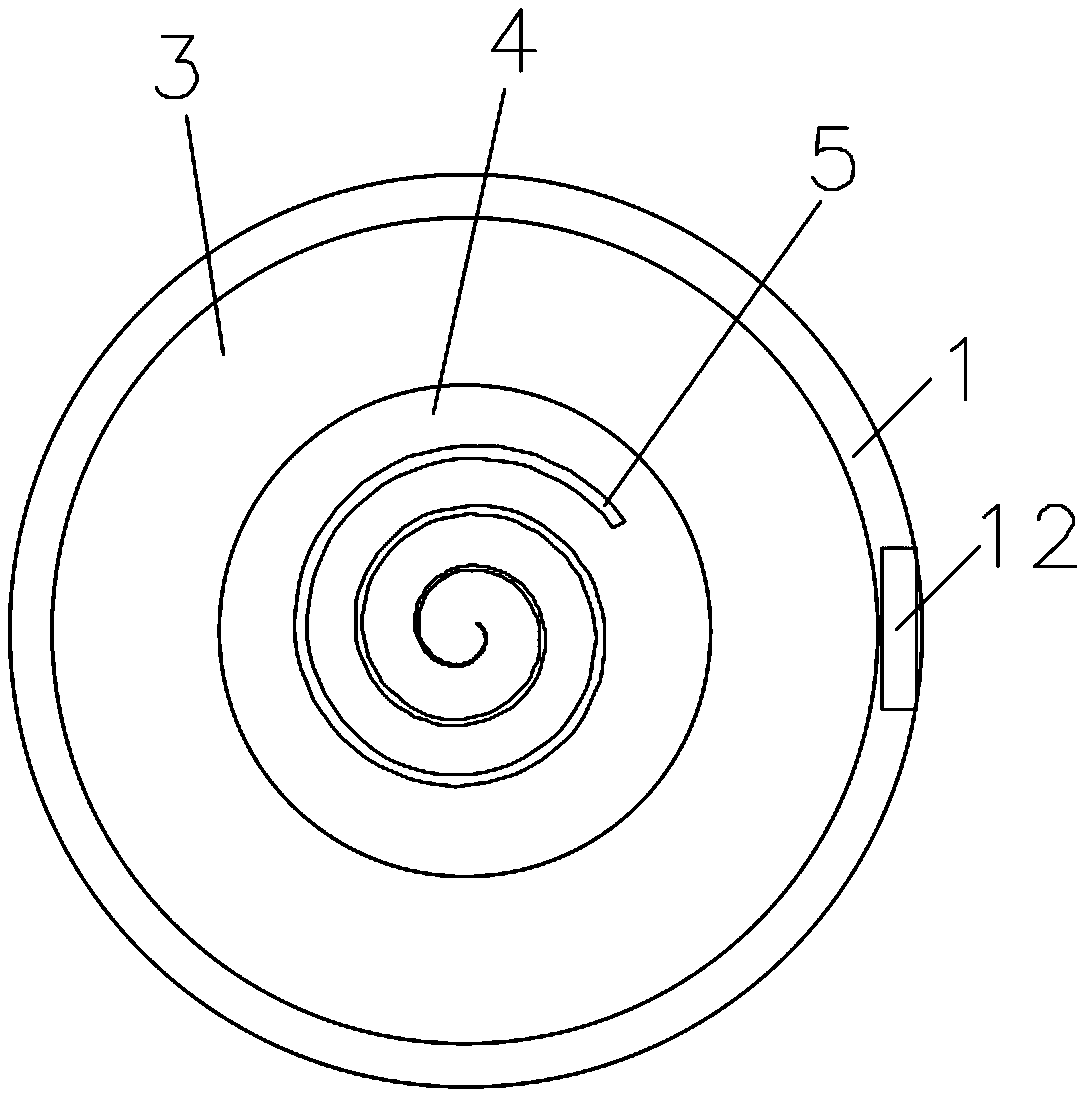

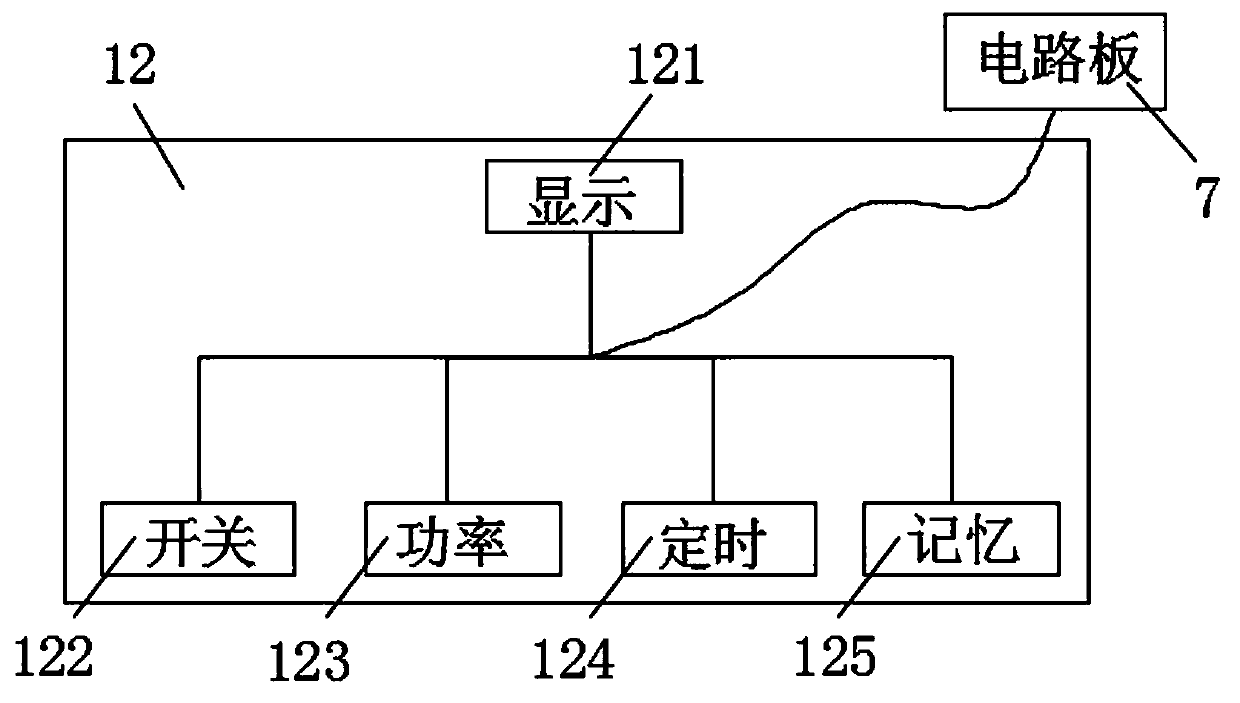

[0020] like Figure 1-2 As shown, a ceramic or purple sand electric ceramic furnace includes a hollow furnace body 1 which is integrally fired and formed, and its material is purple sand, ceramics or stoneware. Feet 14, a number of heat dissipation holes 15 are provided on the furnace body 1 between the adjacent pads 14, a base plate 2 is installed at the bottom of the furnace body 1, a panel 3 is installed on the top of the furnace body 1, and a heating furnace tray 4 is arranged below the panel 3, and the heating furnace A heating furnace core 5 is arranged inside the pan 4, and the heating furnace pan 4 is fixed above the base plate 2 through a plurality of support rods 6. A circuit board 7 and a fan 8 are coaxially installed between the heating furnace pan 4 and the base plate 2 from top to bottom, and the circuit The plate 7 and the fan 8 are fixed on the same circular plastic disk 16 by bolts, and the circular plastic disk 16 is sheathed on each support rod 6, and each s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap