A computer cooling fan assembly device

A heat dissipation fan and assembly device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as difficult to meet the use of screwing machines, prone to danger, improper operation, etc., to save labor, ensure accuracy, Assembly quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

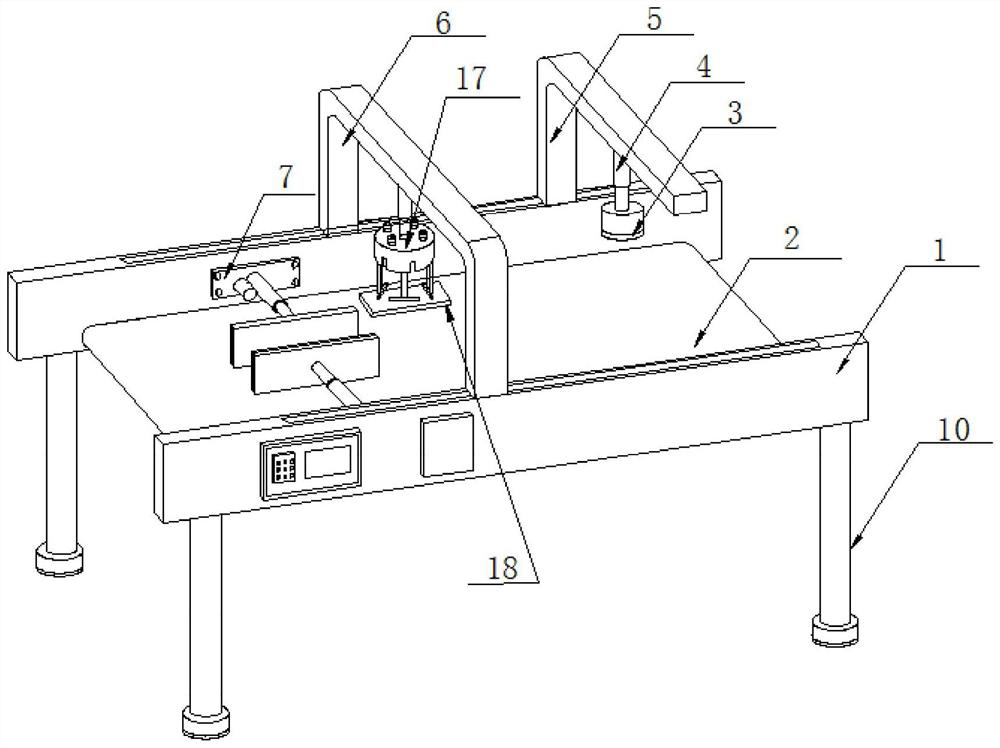

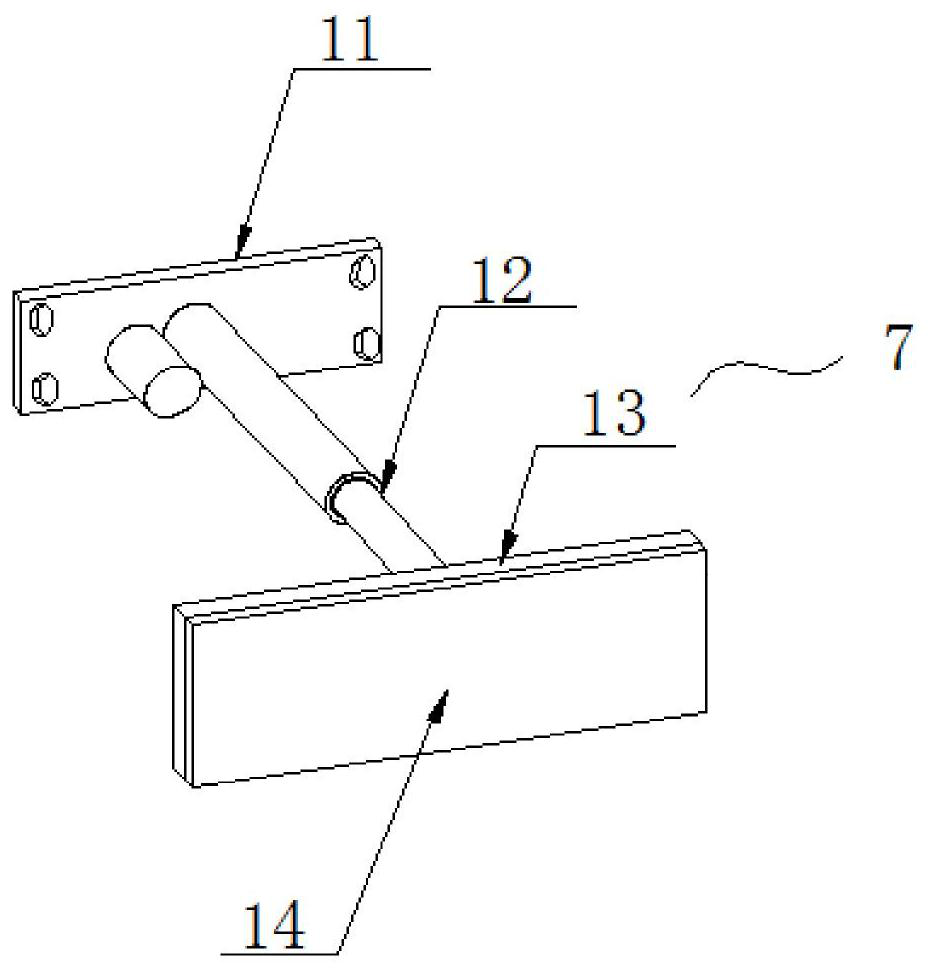

[0029] see Figure 1~4 , in an embodiment of the present invention, a computer cooling fan assembly device includes an assembly platform 2, a chassis positioning mechanism 7, a fan positioning and assembly mechanism 17, and a detection mechanism 3, wherein the assembly platform 2 is fixedly arranged on two supporting carriages 1, and the chassis positioning mechanism 7 is arranged on the assembly platform between the supporting carriages, the fan positioning assembly mechanism and the detection mechanism 3 can be slidably arranged along the extending direction of the supporting carriages; It is characterized in that,

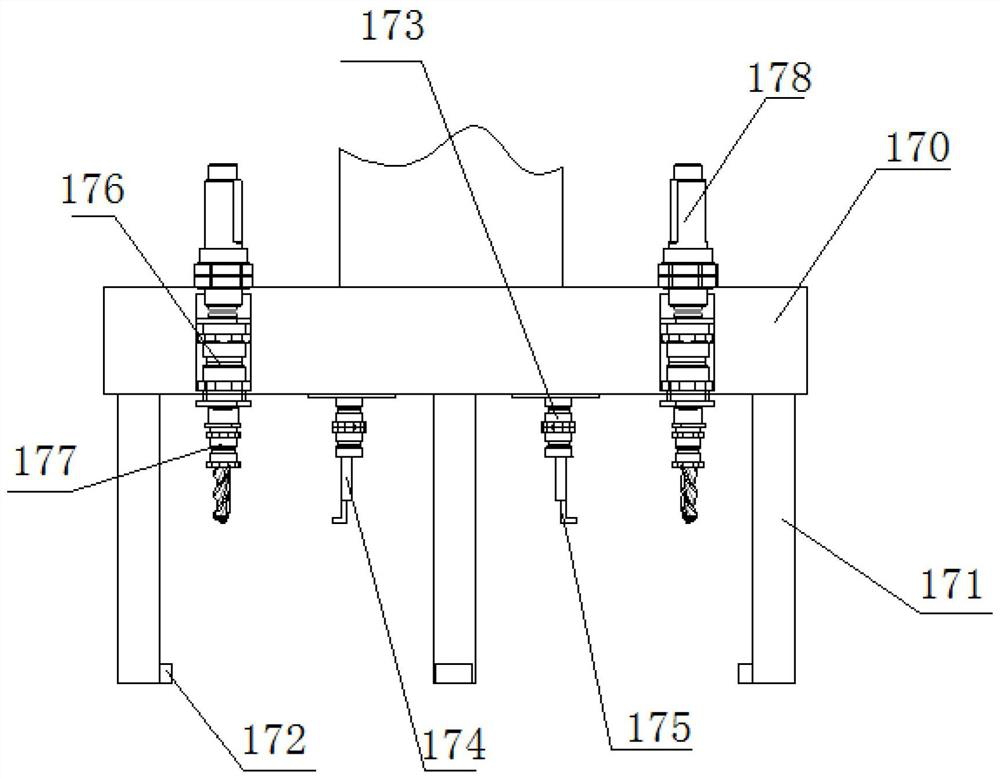

[0030] The fan positioning and assembly mechanism 17 includes a positioning plate 170, a fan positioning and grasping component, an attitude adjustment component and a screwing component, wherein the positioning plate 170 is provided with a fan positioning and grasping component capable of centrally grasping the fan;

[0031] A plurality of screwing assemblies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com