Chamfering device for polyethylene plastic lined composite pipe

A technology of chamfering device and composite pipe, which is applied in metal processing and other directions, can solve the problems of reducing work efficiency, low water absorption, increasing production cost and working time, etc., and achieves the effect of accelerating rounding cutting and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

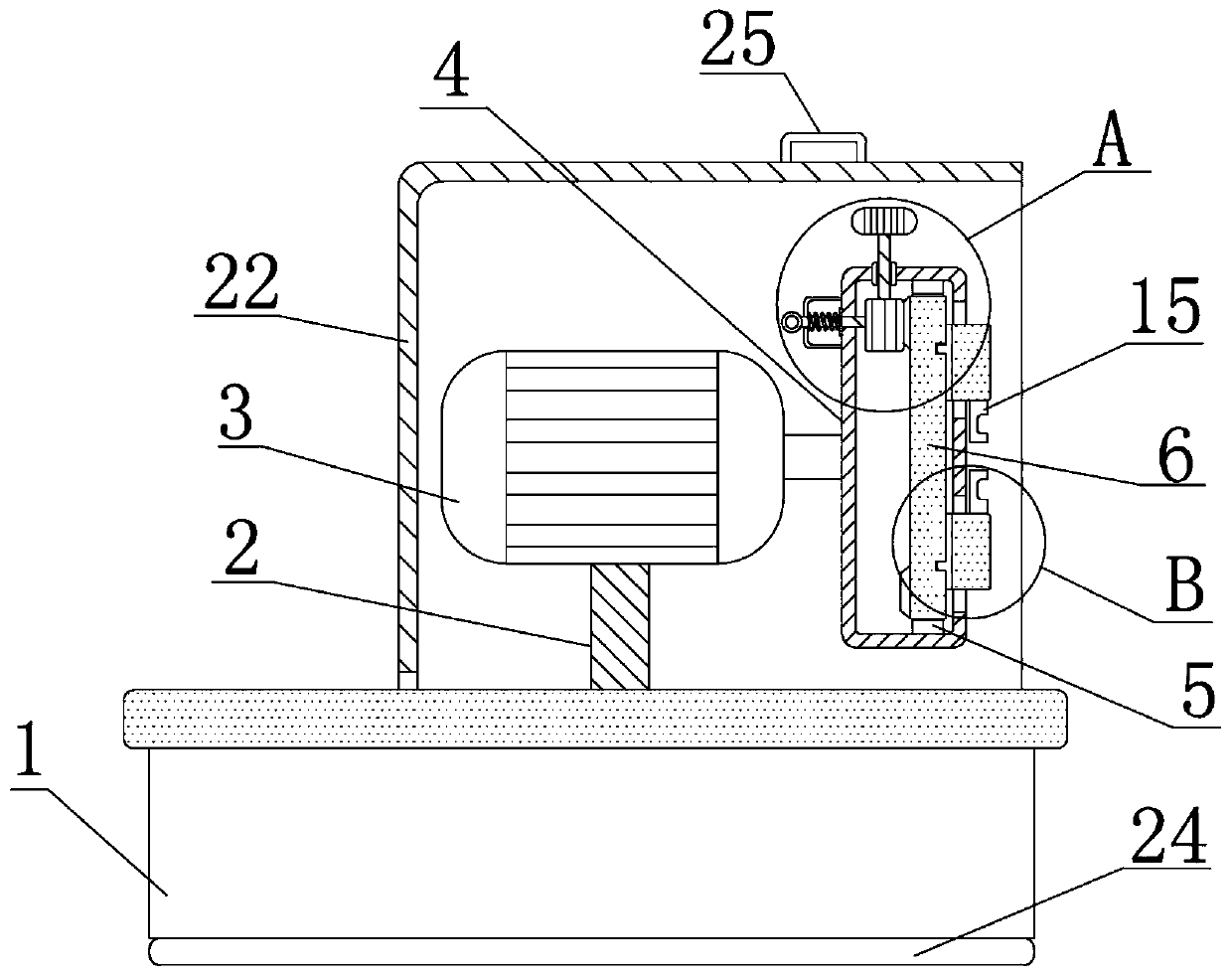

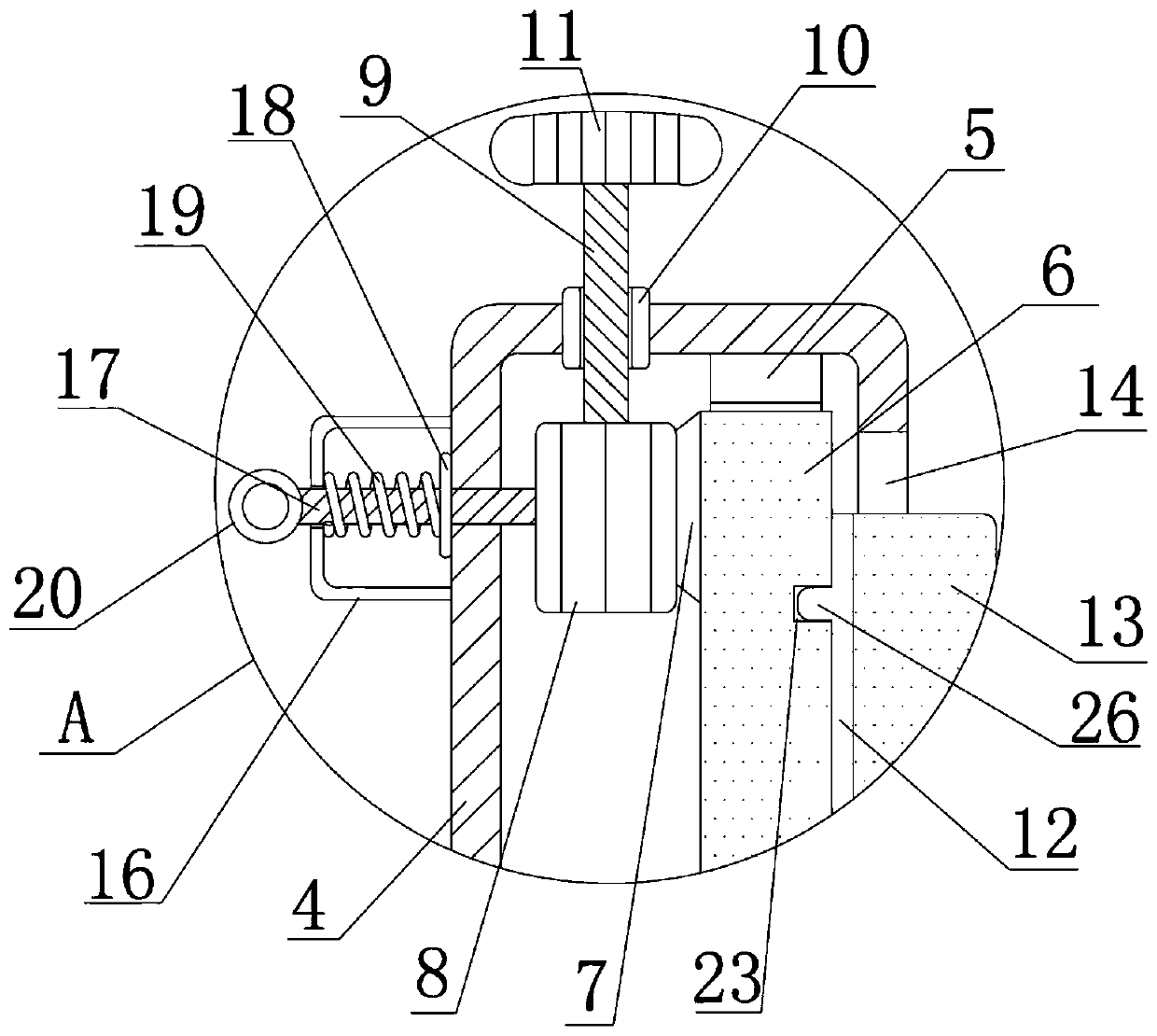

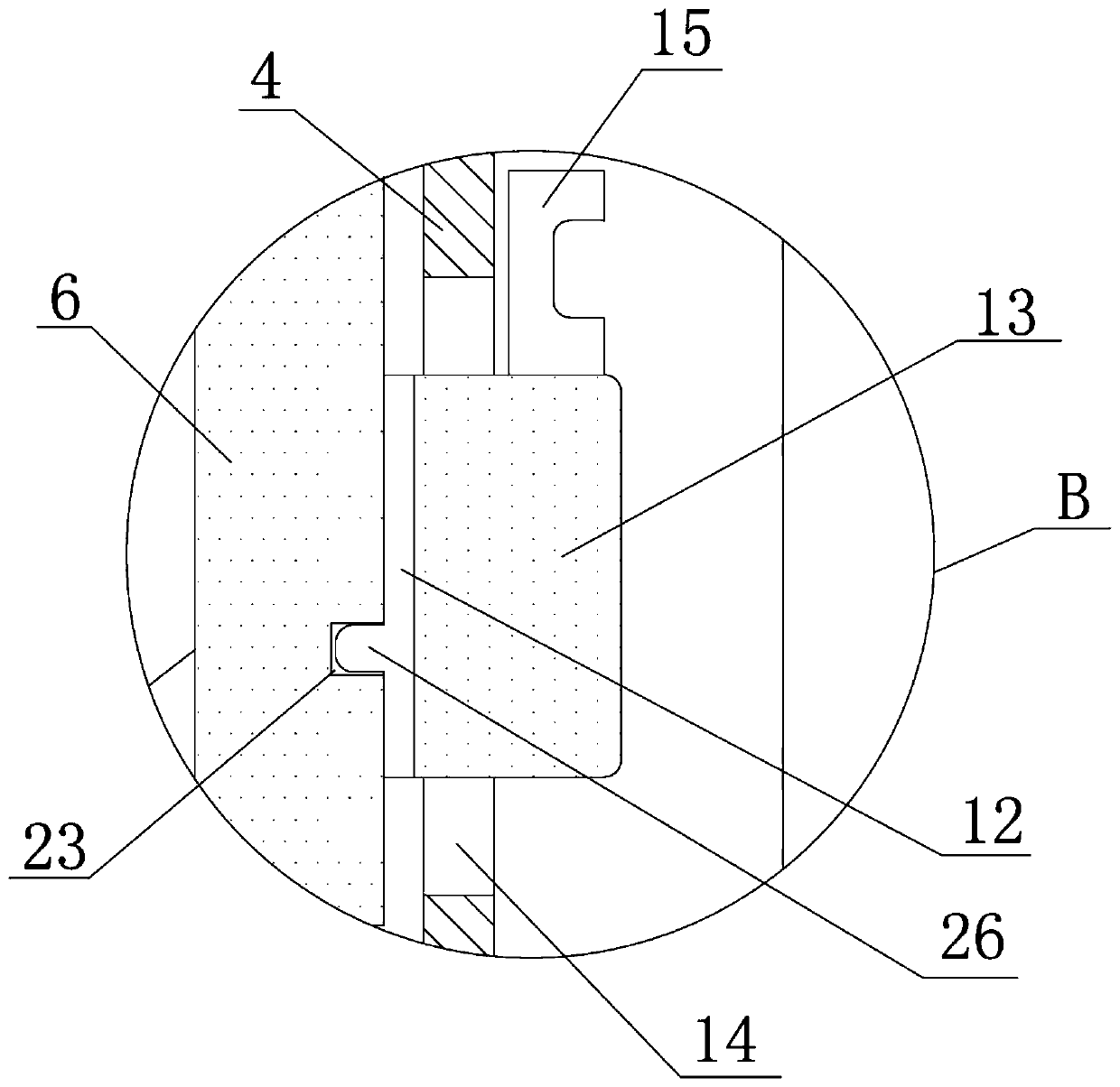

[0033] See Figure 1-6 , A polyethylene lined plastic composite pipe chamfering device, including a base 1, the bottom of the base 1 is processed with a rubber pad 24, the rubber pad 24 is used to prevent the device from moving, making the device more stable during operation, the top of the base 1 is processed with The inner wall of the mounting groove 21 is slidably clamped with a top cover 22, the top cover 22 is used to protect the device from dust, and the top of the top cover 22 is fixedly connected with a curved rod 25, which makes the top cover 22 easy to slide. The top of the base 1 is fixedly welded with a bracket 2, and the top of the bracket 2 is fixed with a motor 3. The model of the motor 3 is ECMA-E11320RS, the output end of the motor 3 is fixed with a round box 4, and the motor 3 rotates to drive the round box 4 to rotate As a primary transmission, the inner wall of the round box 4 is rotatably connected with a circular plate 6 through the first bearing 5. The bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap