Leather shoe fabric tailoring equipment for leather shoe processing

A leather shoe and fabric technology, which is applied in the field of leather shoe fabric cutting equipment for leather shoe processing, can solve the problems of low cutting efficiency, achieve a high degree of automation, and expand the effect of pressing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

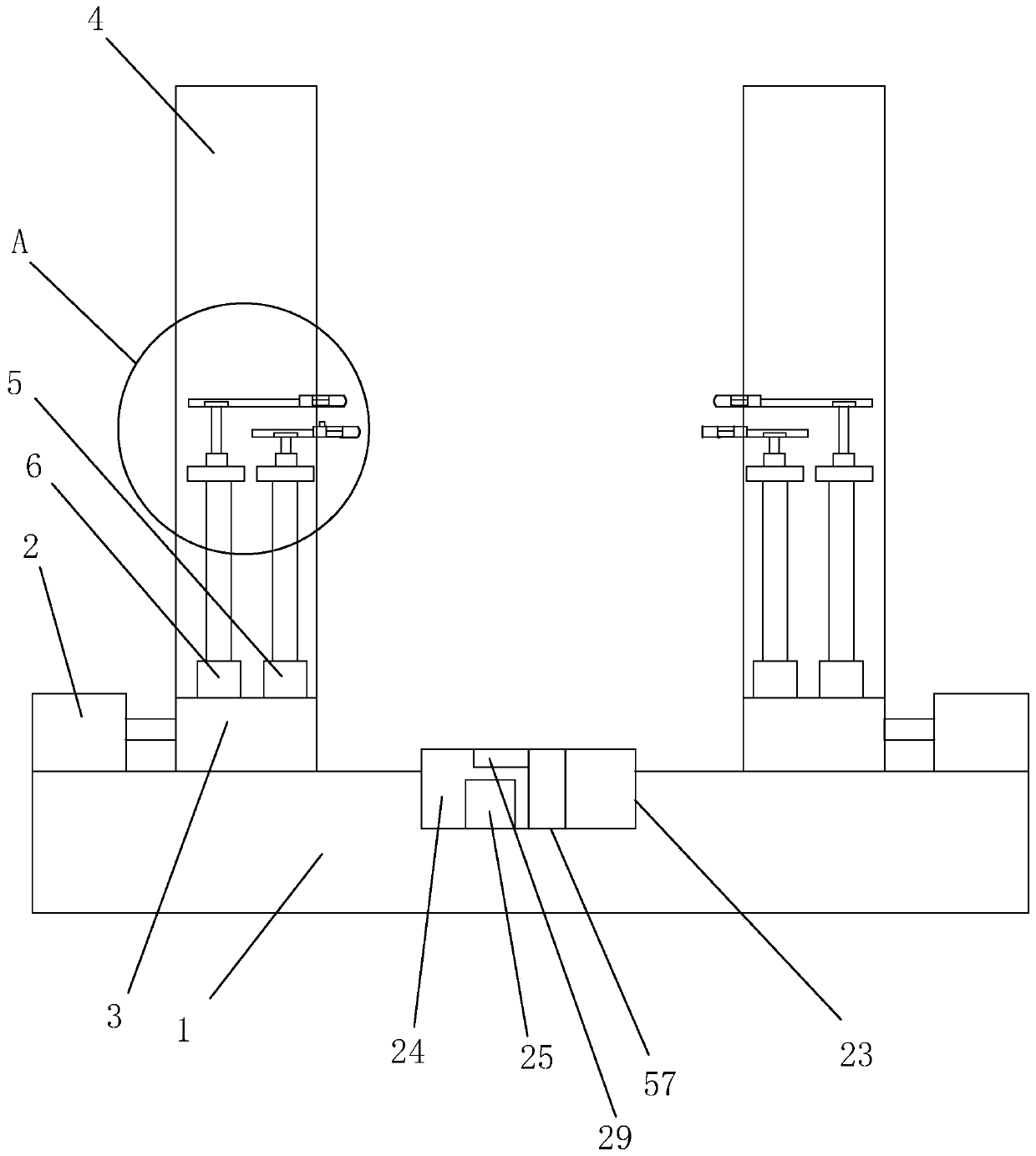

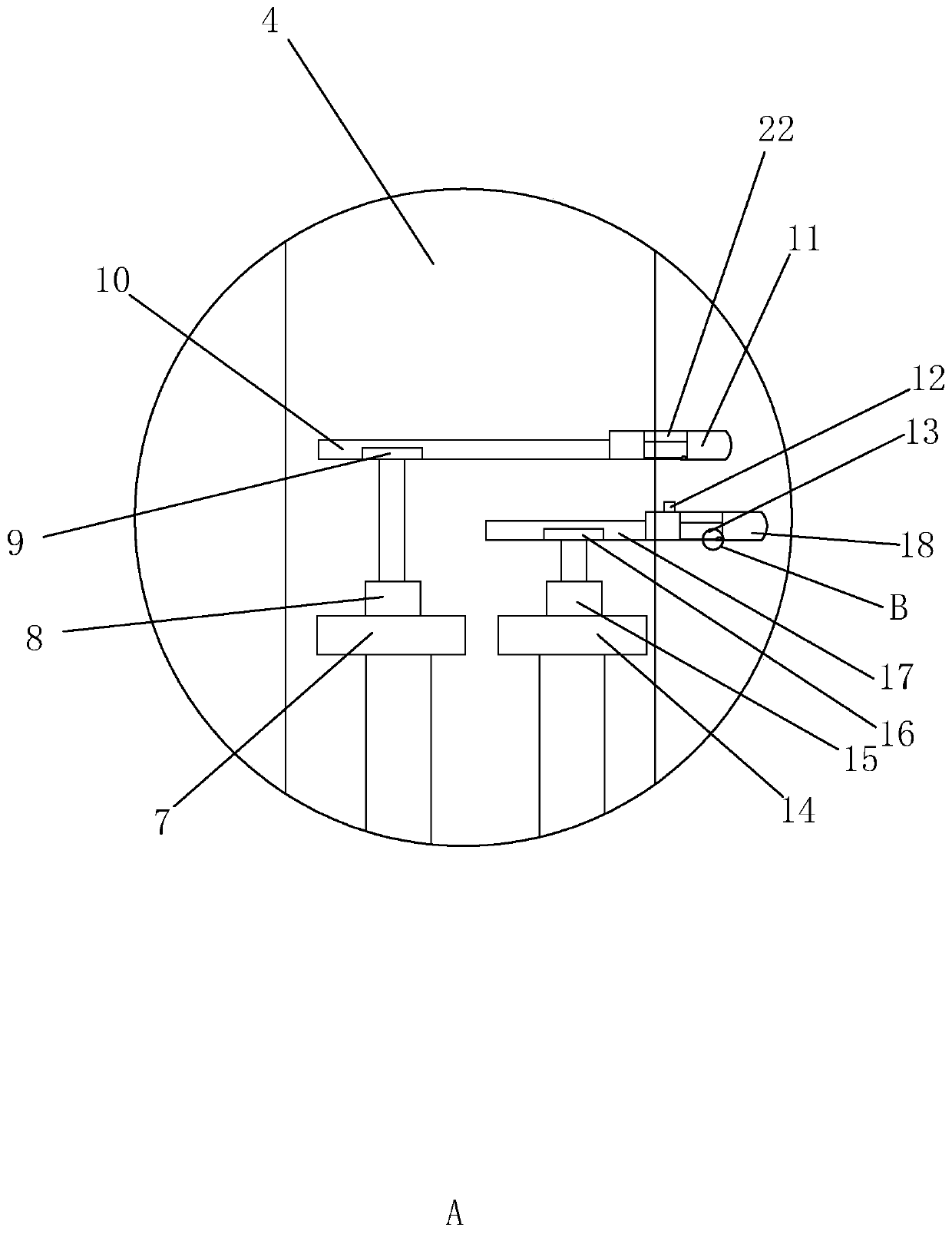

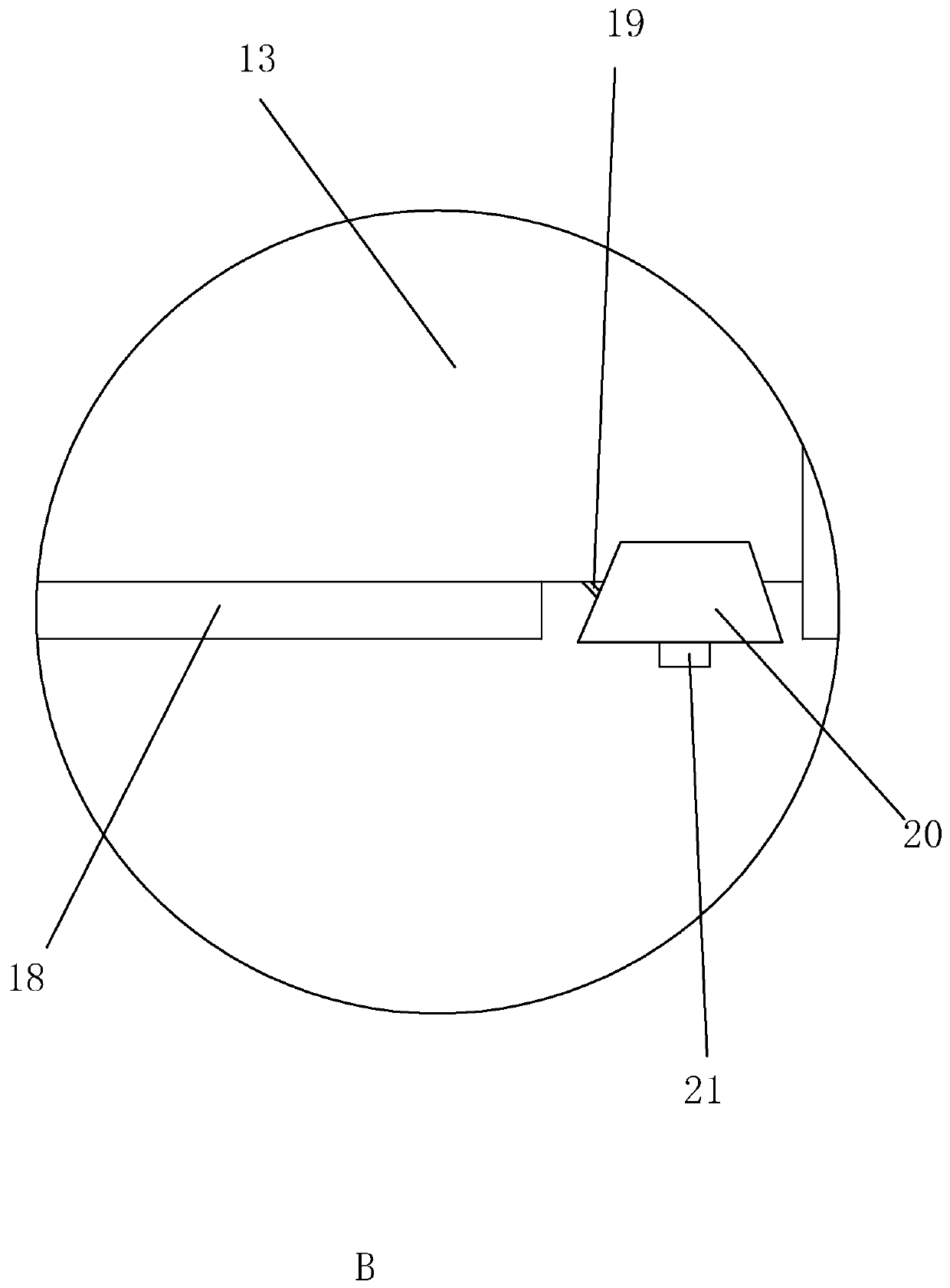

[0028] The present invention will be further described with reference to the accompanying drawings.

[0029] A leather shoe fabric cutting equipment for leather shoe processing, comprising a workbench 30, the workbench 30 is connected with a top plate 31, the top of the top plate 31 is fixedly connected with a lifting cylinder 32, and the lifting cylinder 32 is connected with a pressing device to lift The cylinder 32 can drive the pressing device to move up and down. The pressing device includes four pressing plates 33 connected end to end, and the four pressing plates 33 form a polygonal shape.

[0030] Wherein the two compression plates 33 are integrally connected with a stop rod 34 that runs through the adjacent compression plates 33, the stop rod 34 can play a guiding role, and the one end of the stop rod 34 away from the compression plate 33 is integrally connected to a limited The position disc 35, the limit disc 35 limits the separation of two adjacent pressing plates 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com