A pipe winding coating machine and winding coating method thereof

A coating machine and pipeline technology, applied in the direction of metal material coating process, coating, etc., can solve the problems affecting the use of the winding machine, affecting the support of the rollers, etc., to ensure the anti-corrosion effect, avoid bumps, and increase the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

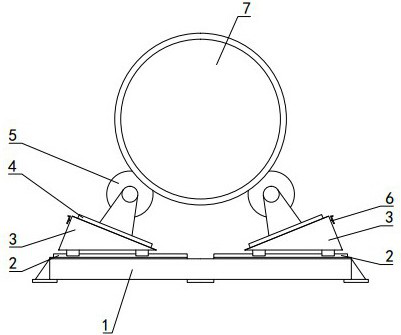

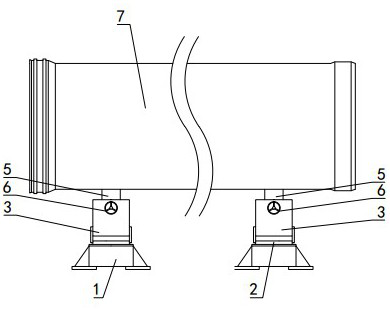

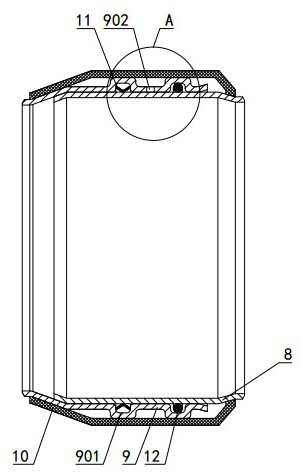

[0037] Figure 1~11 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~11 The present invention will be further described.

[0038] A pipe winding coating machine, comprising a support device and an extruder arranged on one side of the support device, the support device includes a plurality of sets of supporting rollers 5 arranged side by side, a detection device and a translation device, and each set of supporting rollers 5 includes Two symmetrically arranged on both sides of the pipeline 7, each set of idler rollers 5 is connected with a power device that drives it to rotate, each set of idler rollers 5 are rotated and installed on a translation device, and the translation device pushes the idler rollers 5 to move closer to or away from the pipeline 7, each set of rollers 5 is provided with a detection device for detecting the outer diameter of the pipe 7 on the rear side of the feed direction of the pipe 7, and the detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com