A material distribution device of a double-screw packaging machine

A technology of a material distribution device and a packaging machine, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, etc., can solve the problems affecting the feeding at the inlet, material accumulation, and whether there are bags at the outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

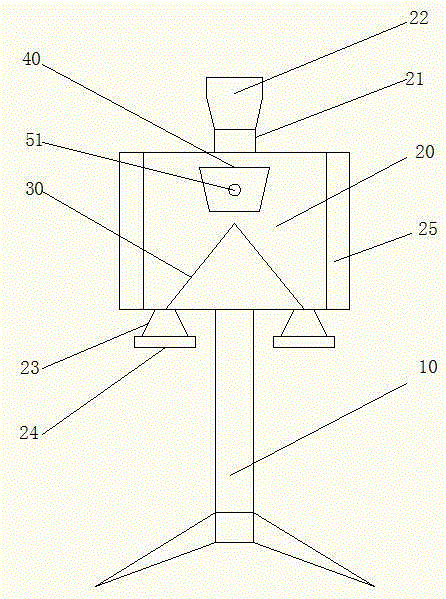

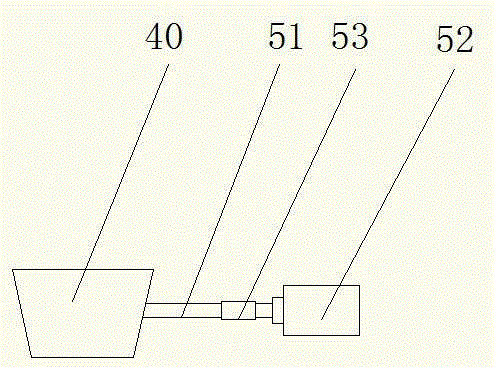

[0018] Such as figure 1 with figure 2 As shown, a distributing device of a double-screw packaging machine is used to divide the material poured in from the inlet 21 to two outlets 23. The double-screw packaging machine includes a frame 10 with a storage bin 20 , the feed port 21 of the storage bin 20 is provided with a feed hopper 22, and the two discharge ports 23 are provided with a discharge nozzle 24 communicating with the discharge port 23, and the storage bin 20 is provided with two opposite discharge ports. The "︿" shape distribution plate 30 of 23 is used to lead the materials to the two discharge ports 23 respectively, and the storage bin 20 is provided with a feeder 40 between the material inlet 21 and the distribution plate 30 for The material entering through the material inlet 21 is transferred to the material distribution plate 30 , and the storage bin 20 is also equipped with a driving device for driving the feeder 40 to swing to the two material outlets 23 . ...

Embodiment 2

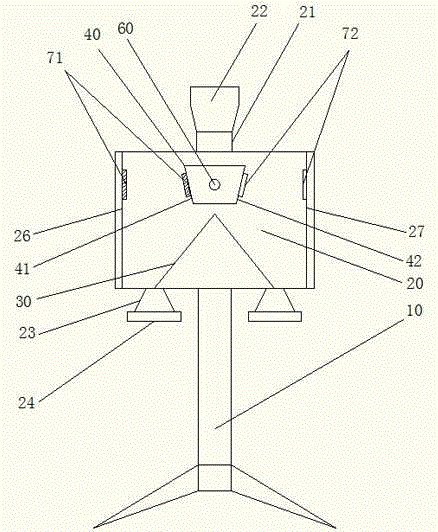

[0022] Such as image 3 As shown, a distributing device of a double-screw packaging machine is used to divide the material poured in from the inlet 21 to two outlets 23. The double-screw packaging machine includes a frame 10 with a storage bin 20 , the feed port 21 of the storage bin 20 is provided with a feed hopper 22, and the two discharge ports 23 are provided with a discharge nozzle 24 communicating with the discharge port 23, and the storage bin 20 is provided with two opposite discharge ports. The "︿" shape distribution plate 30 of 23 is used to lead the materials to the two discharge ports 23 respectively, and the storage bin 20 is provided with a feeder 40 between the material inlet 21 and the distribution plate 30 for The material entering through the material inlet 21 is transferred to the material distribution plate 30 , and the storage bin 20 is also equipped with a driving device for driving the feeder 40 to swing to the two material outlets 23 .

[0023] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com