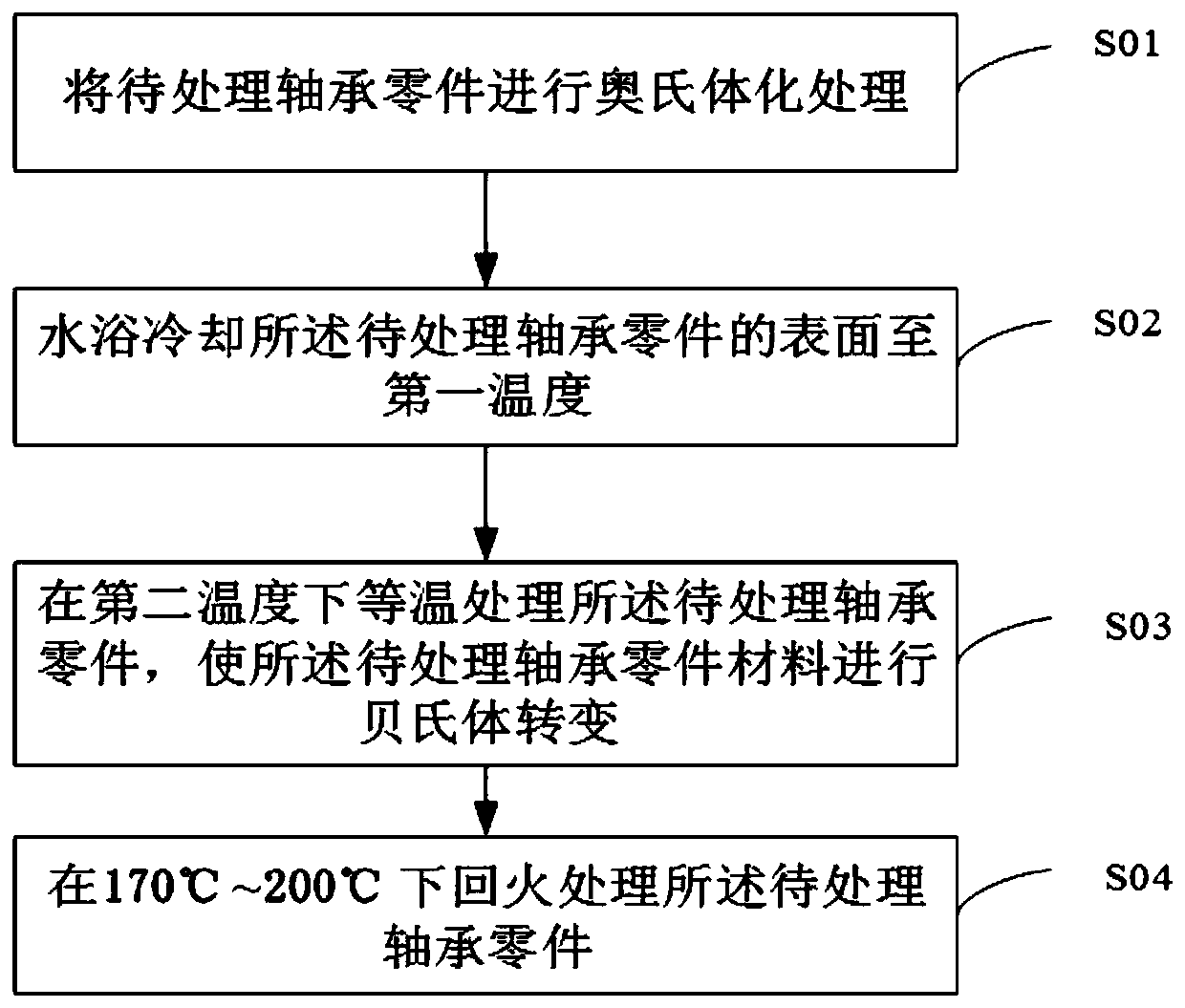

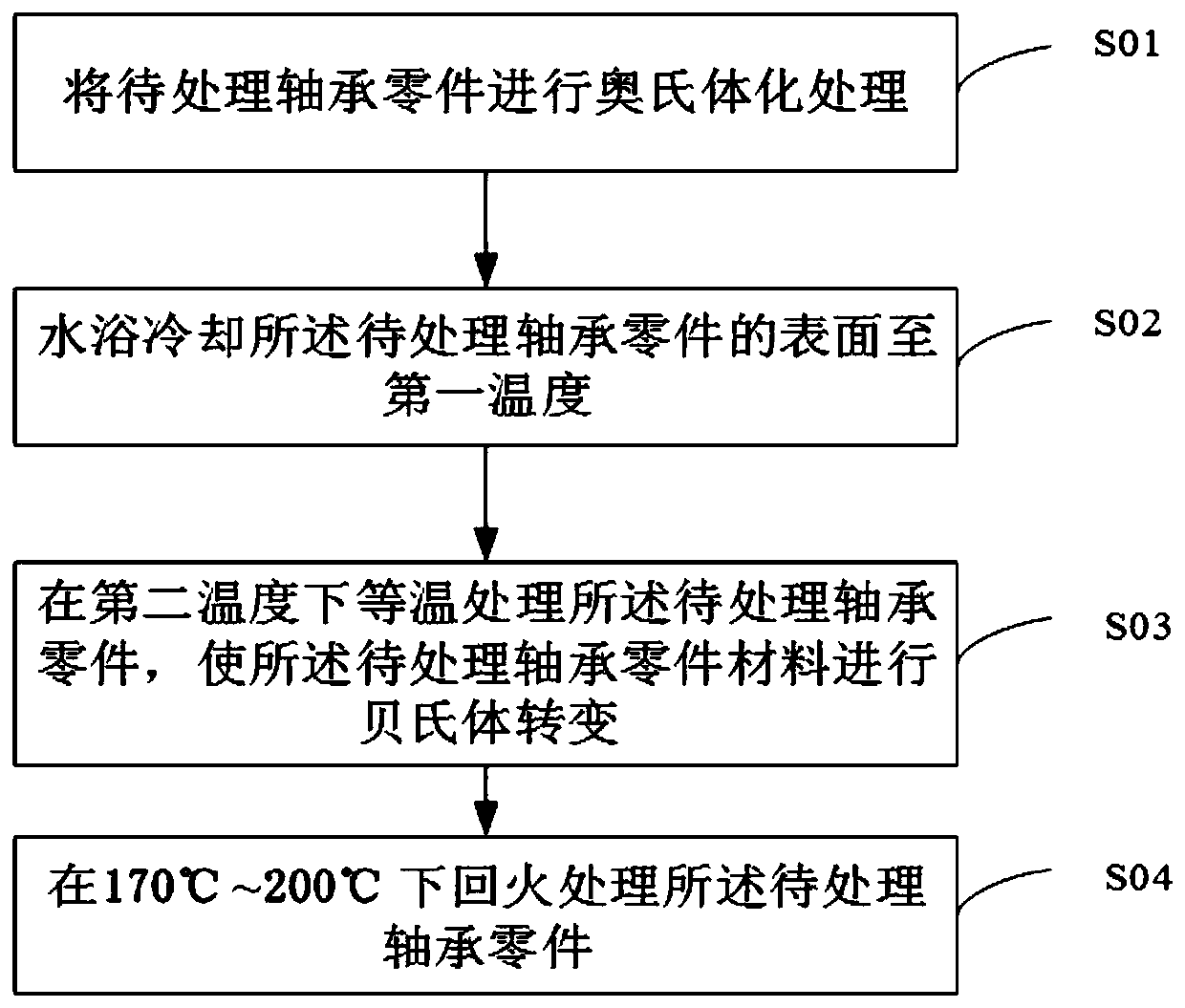

Thermal treatment method of nano-bainite bearing and bearing manufactured by adopting thermal treatment method

A technology of nano-bainite and heat treatment method, applied in the field of bearing manufacturing, can solve problems such as environmental pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0048] Example 1: Using a high-carbon chromium nano-bainite bearing steel, the main chemical composition mass percentages are, C: 0.92, Si: 1.51, Mn: 0.45, Cr: 1.42, Mo: 0.20. After the bearing steel is spheroidized and annealed, it is processed into bearing parts with a wall thickness of 40mm. Then heat the bearing parts to 830°C for 40 minutes, put them in 70°C warm water for 10 seconds and then take them out. After standing for 65 seconds, add water again and cool for 6 seconds. After the surface temperature reaches 135°C, put the bearing ring into 200°C inert Isothermal treatment is carried out in an atmosphere furnace. After holding for 3.5 hours, the bainite formation content reaches 50%. It is taken out and cooled, and finally it is held in a furnace at 175°C for 1 hour for tempering. After this method, the surface hardness of the bearing ring is 62.5HRC, the core hardness is 58.6HRC, and the unnotched impact toughness is 68J / cm. 2 .

Example

[0049] Example 2: Using a carburized nano-bainite bearing, the main chemical composition mass percentages are: C: 0.23, Si: 1.46, Mn: 0.62, Cr: 1.56, Ni: 0.59, Mo: 0.25. The bearing steel is processed into bearing parts, and the wall thickness of the bearing ring is 85mm. Then carburizing treatment is carried out, and the C content on the surface after carburizing reaches 0.95 wt.%. The carburized bearing parts are spheroidized and tempered at high temperature. Then heat the bearing parts to 865°C for 60 minutes, put them in 50°C warm water for 25s, then take them out, let stand for 100s and then add water to cool for 10s, the surface temperature reaches 155°C, put the bearing ring into 185°C inert Isothermal treatment is carried out in an atmosphere furnace. After holding for 7.5 hours, the amount of bainite produced reaches 65%, then it is taken out and cooled, and finally it is held in a furnace at 180°C for 1 hour for tempering. After being processed by this method, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heart hardness | aaaaa | aaaaa |

| Heart hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com