Visible soil destruction mode capture device

A failure mode and capture device technology, applied in the field of geotechnical engineering, can solve the problems of lack of accuracy in manual sand spreading, lack of multi-directional loading conditions, single loading method, etc., to achieve uniform and flexible arrangement of colored sand, efficient and labor-saving sand spreading , the effect of diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

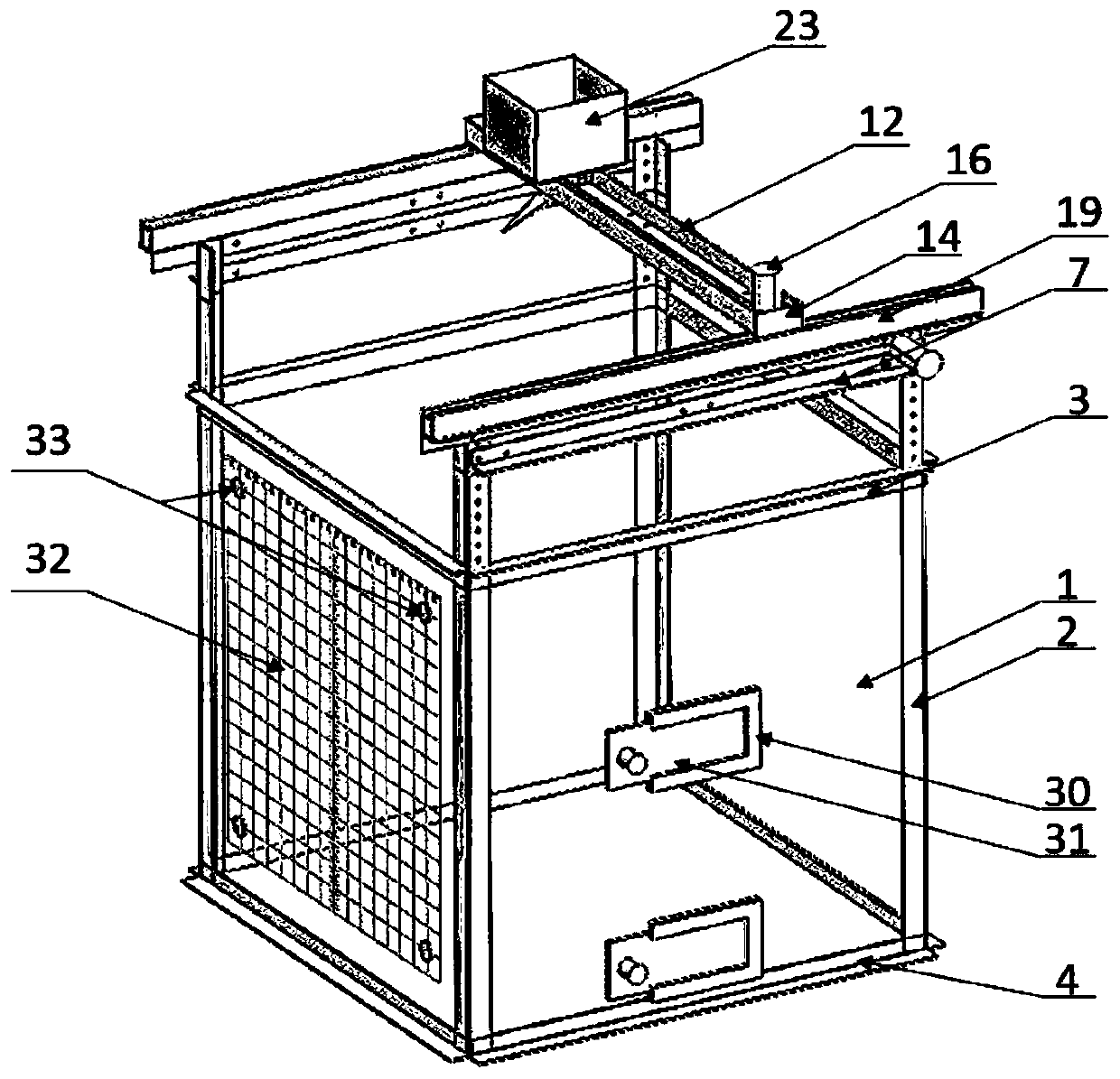

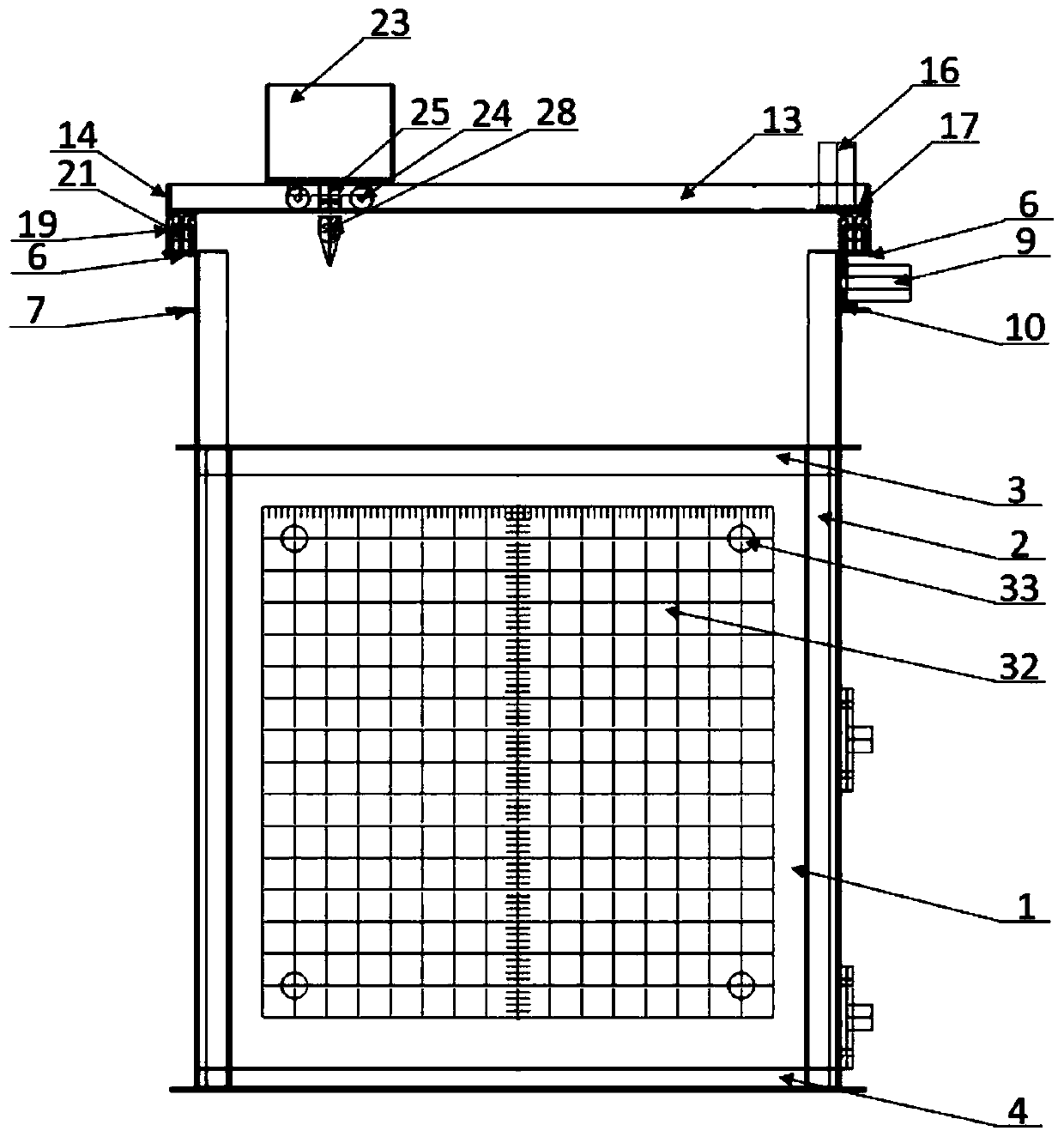

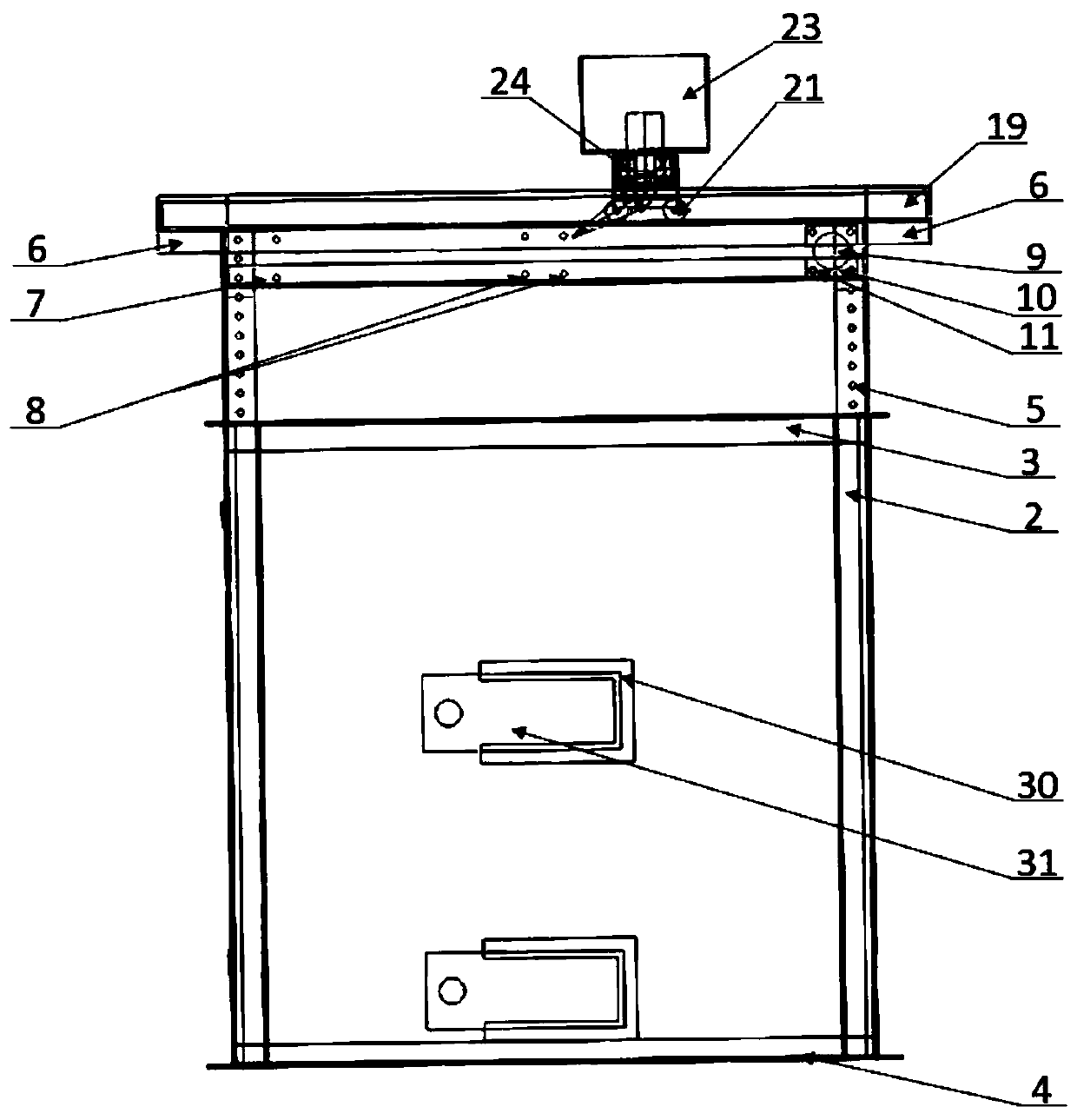

[0040] A visual soil failure mode capture device, which consists of a soil model box, a loading system, a sand spreading device, a sand unloading device and a magnetic scale plate. The loading system and the sand spreading device are arranged above the soil model box. The loading system includes a horizontal The loading device, the vertical loading device, the sand unloading device and the magnetic scale plate are respectively arranged on the adjacent two sides of the model box, and the sand spreading device can move left and right, front and rear above the soil model box and sprinkle sand into the model box. The horizontal loading device relies on the first separate short-type hydraulic jack to push the piston rod forward through pressurization, thereby applying pressure to the model, and forming a reaction force structure through the interaction of the outer support frame to maintain its own stability. The vertical loading device relies on the second separated short hydraulic...

Embodiment 2

[0047] This embodiment is based on Embodiment 1, and further optimizes the visual soil failure mode capture device. The structural diagram of the visual soil failure mode capture device is as follows figure 1 As shown, specifically, the soil model box is composed of a box body and an outer support frame. The box body 1 is composed of 5 transparent square transparent polyester resin boards with a thickness of h. The area of the 5 polyester resin boards is L×L, and each of the bottom, front, rear, left and right sides is glued together. A cube without a cover on the upper part is formed to accommodate the model soil. The outer support frame is composed of 12 angle steels, which are welded to form a space cube that is tightly wrapped around the box to prevent the box from being damaged by force and provide counterforce support for the loading system. like figure 2 and image 3 As shown, four vertical angle steels 2 are arranged at the four corners of the model box, the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com