Rotary load smooth control method based on magnetic suspension bearing active stiffness regulation

A magnetic suspension bearing and smooth control technology, applied in attitude control and other directions, can solve problems such as the inability to achieve precise modeling of magnetic suspension bearing stiffness and active regulation of low stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

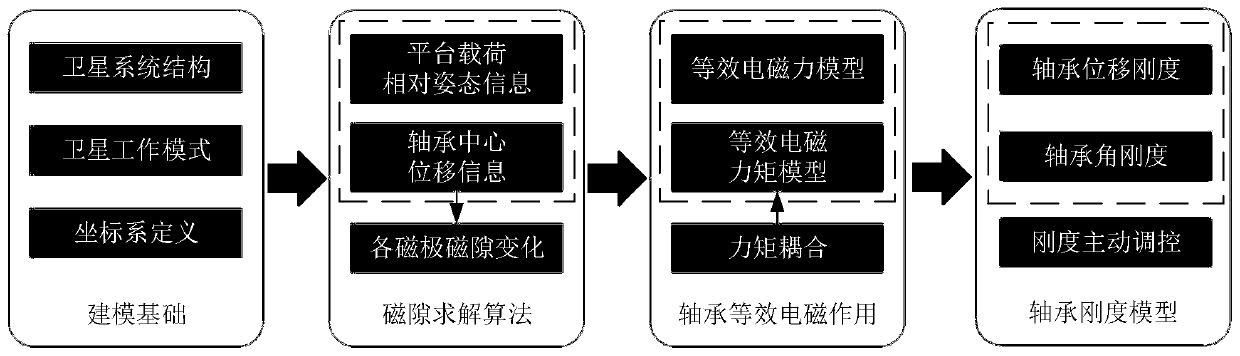

[0022] Specific implementation mode one: combine figure 1 This embodiment will be described. The method for stabilizing rotating loads based on the active stiffness regulation of the magnetic suspension bearing described in this embodiment includes the following steps:

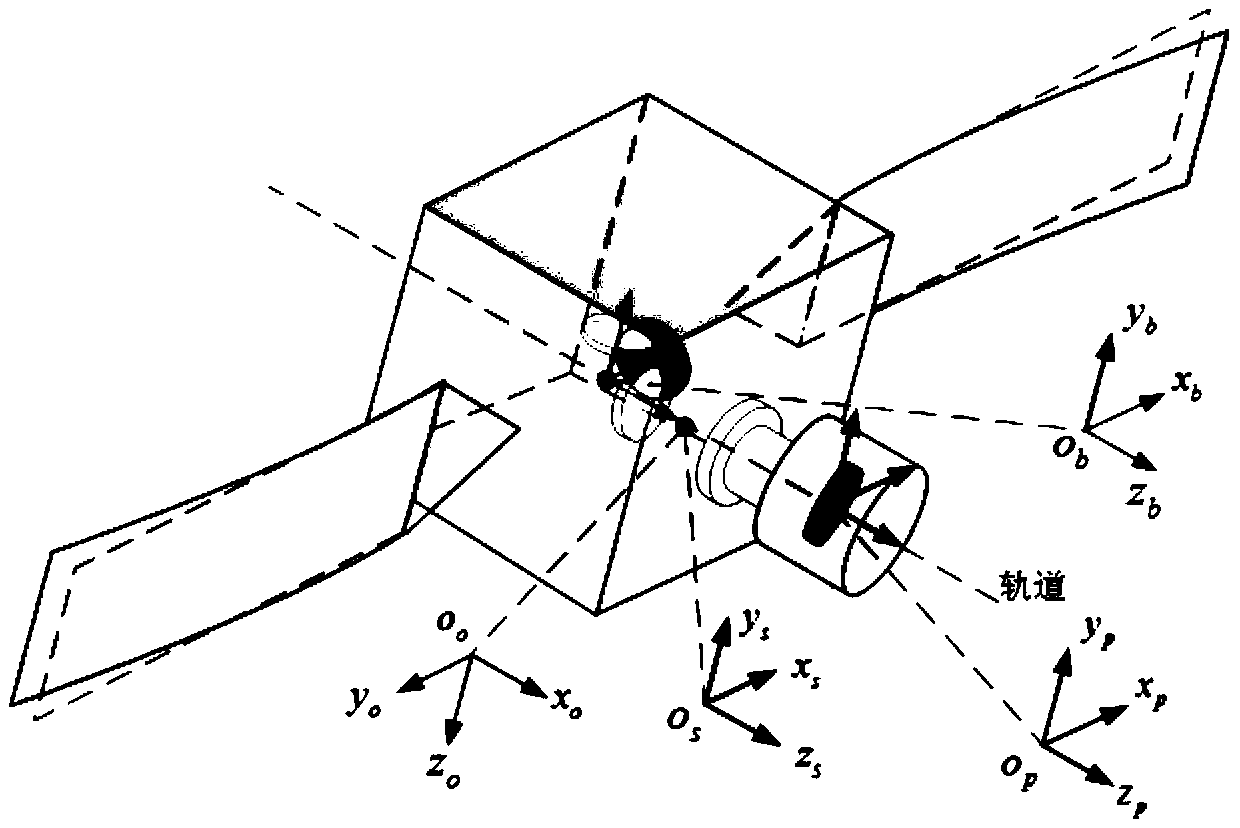

[0023] Step 1. Determine the composition and working mode of the rotating payload satellite system, and define the geocentric equatorial coordinate system oxyz and the orbital coordinate system o o x o the y o z o , The barycentric coordinate system of the rotating payload satellite system o s x s the y s z s , Satellite platform body coordinate system o b x b the y b z b and rotating load body coordinate system o p x p the y p z p ;

[0024] Step 2. According to the spatial relative attitude information of the satellite platform and the rotating load and the displacement information of the center of the magnetic levitation bearing (that is, the center position of the thrust disc or the middle ...

specific Embodiment approach 2

[0031] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the specific process of the step one is:

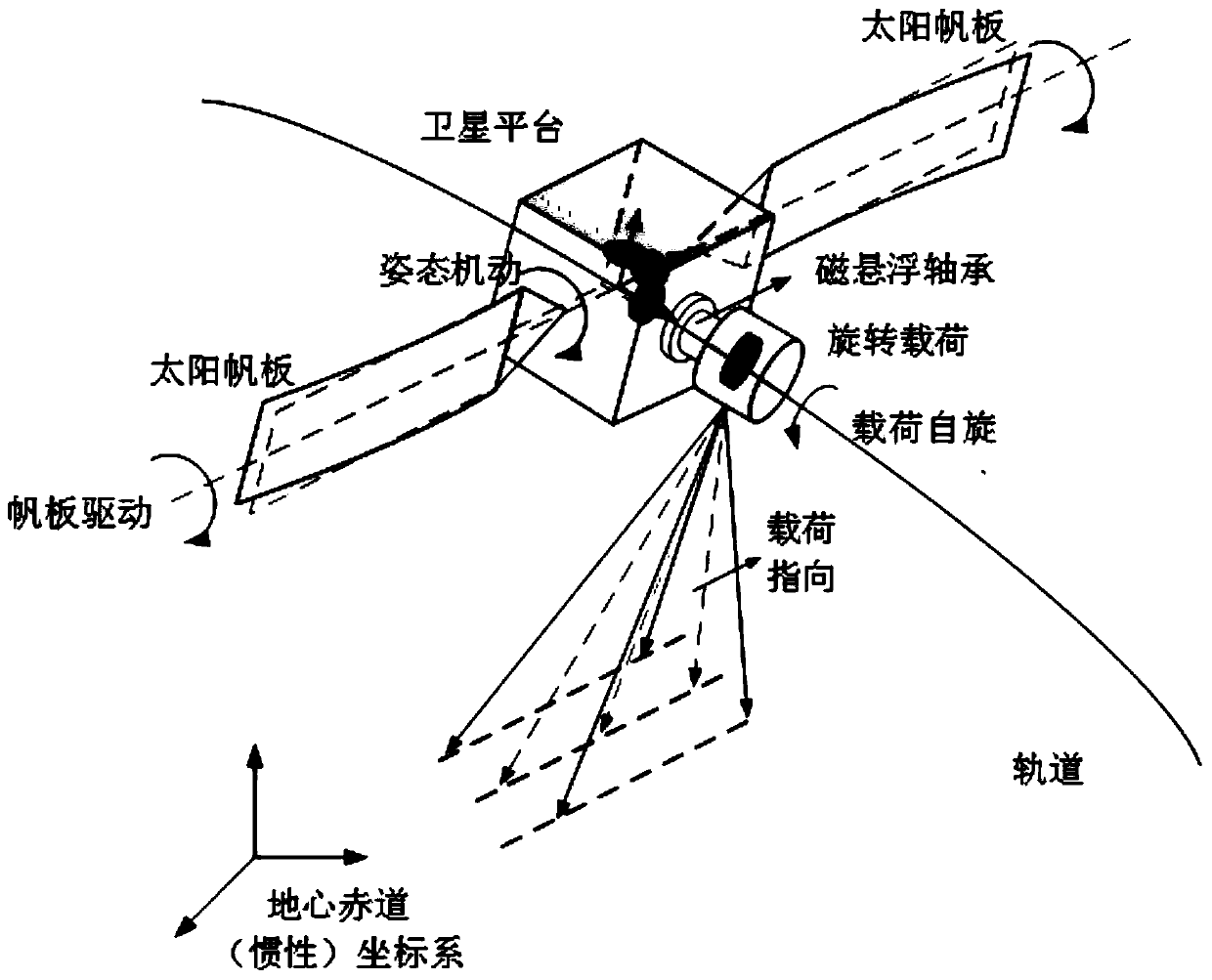

[0032] Such as figure 2As shown, the structure of the satellite system for determining the rotating load includes the satellite platform subsystem, the load subsystem and the rotary joint; the satellite platform subsystem includes: the satellite platform, the platform three-axis orthogonal flywheel and the platform double-sided solar panels; The load subsystem further includes: a rotating load and a flywheel within the load; the rotating joint is a magnetic suspension bearing (and equipped with a mechanical bearing and a drive motor), and the magnetic suspension bearing is composed of a left radial bearing, a right radial bearing, an axial bearing and a rotating shaft Composition, the stator part of the magnetic suspension bearing is fixedly connected with the satellite platform subsystem, and the rotor pa...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 4 This embodiment will be described. The difference between this embodiment and the second embodiment is that the specific process of the second step is:

[0041] Define the vector r 5 Represents the position vector of the desired center of the magnetic suspension bearing pointing to the current center of the magnetic suspension bearing, vector r 6 Represents the position vector of the current center of the magnetic suspension bearing pointing to the action point of the left radial bearing, vector r 7 Represents the position vector where the expected center of the magnetic suspension bearing points to the action point of the left radial bearing, vector r 8 Represents the position vector of the current center of the magnetic suspension bearing pointing to the action point of the right radial bearing, vector r 9 Represents the position vector of the expected center of the magnetic suspension bearing pointing to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com