Distributed inventory scheduling method

A scheduling method and distributed technology, applied in the field of warehousing, can solve the problems of increasing time cost, cargo transportation cost and management cost, unreasonable warehouse allocation, and paralysis of distributed warehousing scheduling, so as to increase the warehousing turnover rate and inventory flexibility, Optimize the allocation or ordering plan and improve the effect of customer service level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

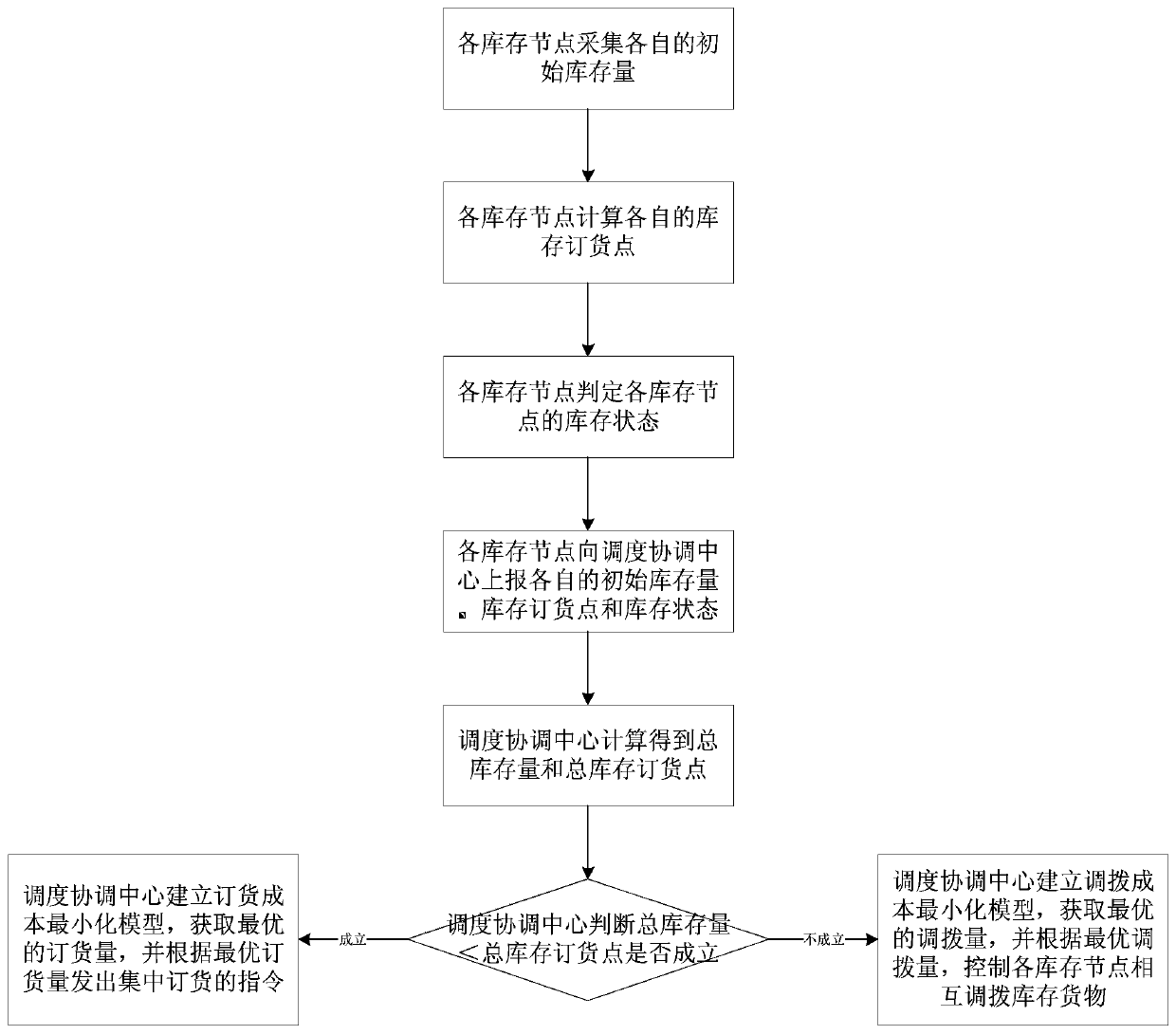

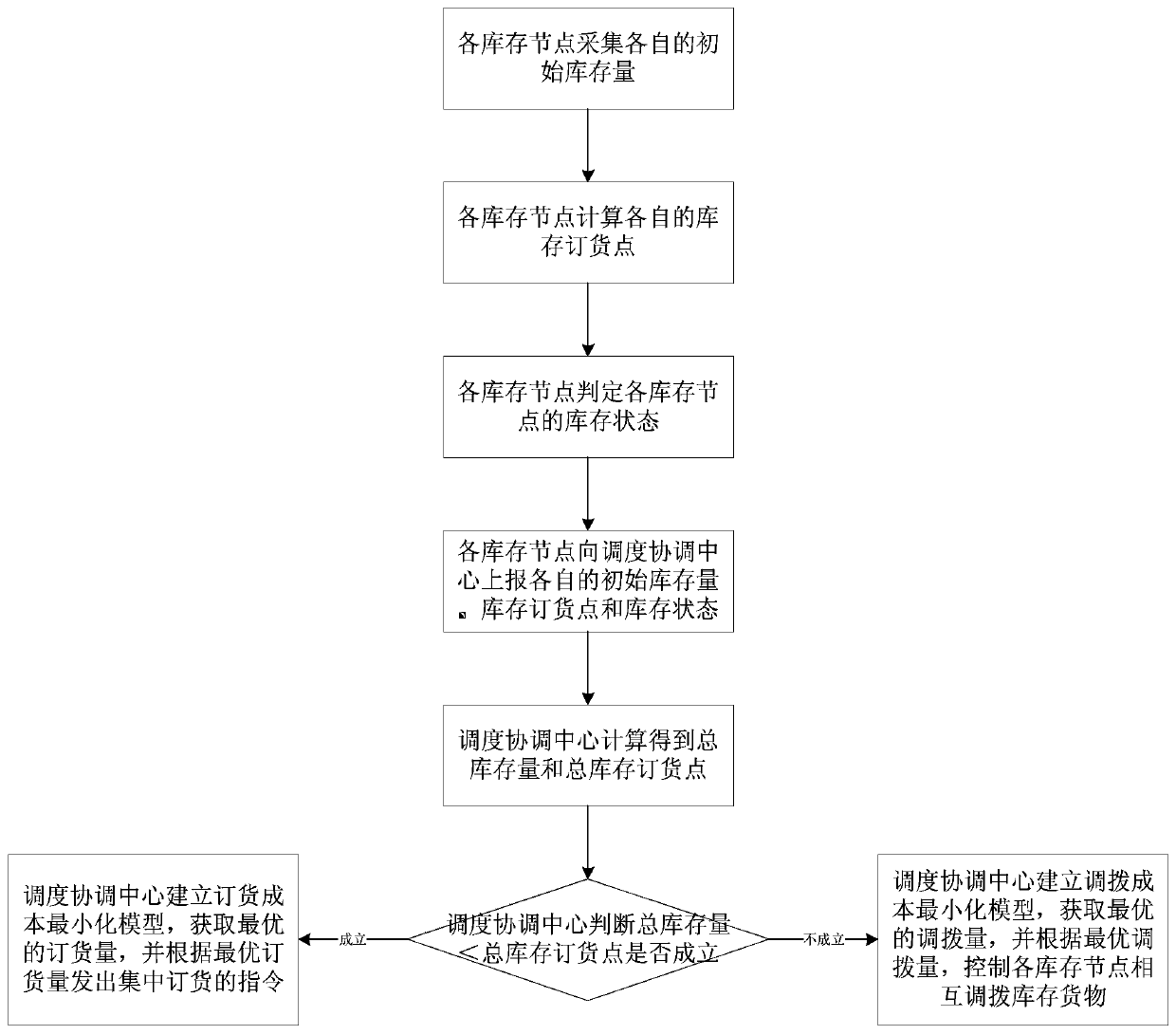

[0043] Such asfigure 1 As shown, a kind of distributed inventory scheduling method provided by the present invention comprises steps:

[0044] S1: Each inventory node collects its own initial inventory; the inventory node represents each warehouse. Each inventory node is equipped with a radio frequency identification module, which can collect real-time inventory information (current inventory of various categories of materials) within the scope. The use of radio frequency identification to collect inventory information within the range (the current inventory of various categories of materials) is an existing technology, and details will not be described here.

[0045] S2: Each inventory node calculates its own inventory order point according to its initial inventory, demand, order lead time, and customer service level; the demand, order lead time, and customer service level of the inventory node are known quantities.

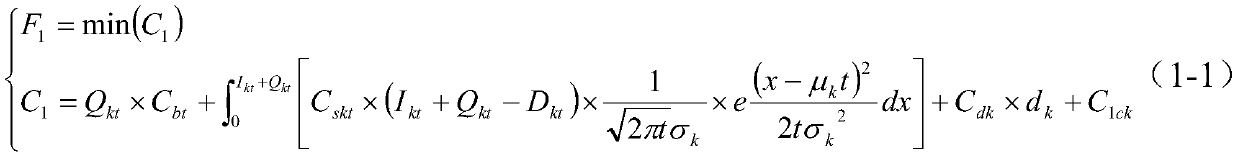

[0046] S3: Each inventory node determines its own invento...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com