Task assignment and path planning method for multi-layer som heterogeneous welding robot

A welding robot and path planning technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low efficiency, harsh operating environment, and inability to guarantee quality, achieve good robustness, optimal path cost, and improve Effects of Robustness and Versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

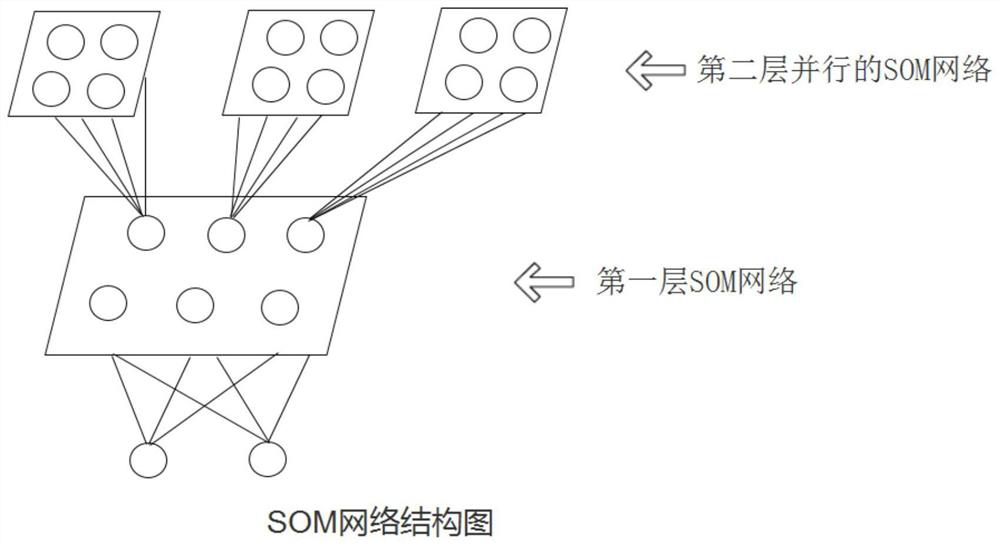

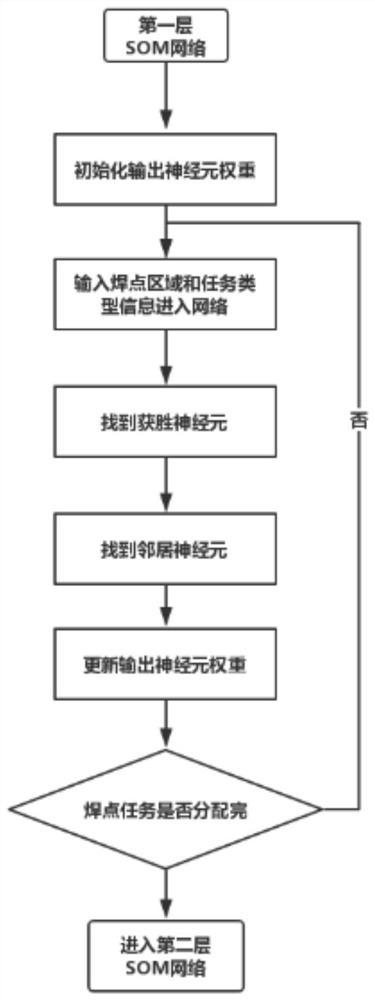

[0060] Such as figure 1 , 2 As shown, the task allocation and path planning method of the multi-layer SOM heterogeneous welding robot disclosed in this embodiment, the specific implementation steps are as follows:

[0061] Step 1: Establish the first-layer SOM neural network model according to the task type of the solder joint, the position area information of the solder joint and the welding robot, train the first-layer SOM neural network model, and complete the rough task assignment of the heterogeneous welding robot system, Output the welding task points required by various types of heterogeneous welding robots to improve the robustness and versatility of the heterogeneous welding robot system.

[0062] Step 1.1: According to the coordinate positions of welding task points and heterogeneous welding robots, the welding task points and heterogeneous welding robots are divided into regions.

[0063] Table 1 Welding task points

[0064]

[0065]

[0066] Table 2 Hetero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com