Electrostatic automatic haircutting system and automatic haircutting method based on magnetic fluid shaping grid

A magnetic fluid and static electricity generation technology, applied in metal processing, etc., to avoid long waiting time for haircuts, improve haircut efficiency, and lower operating threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

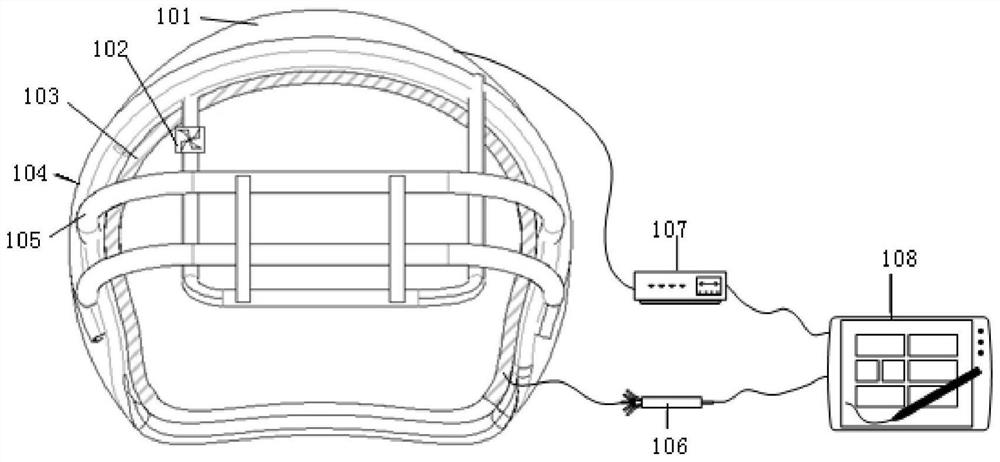

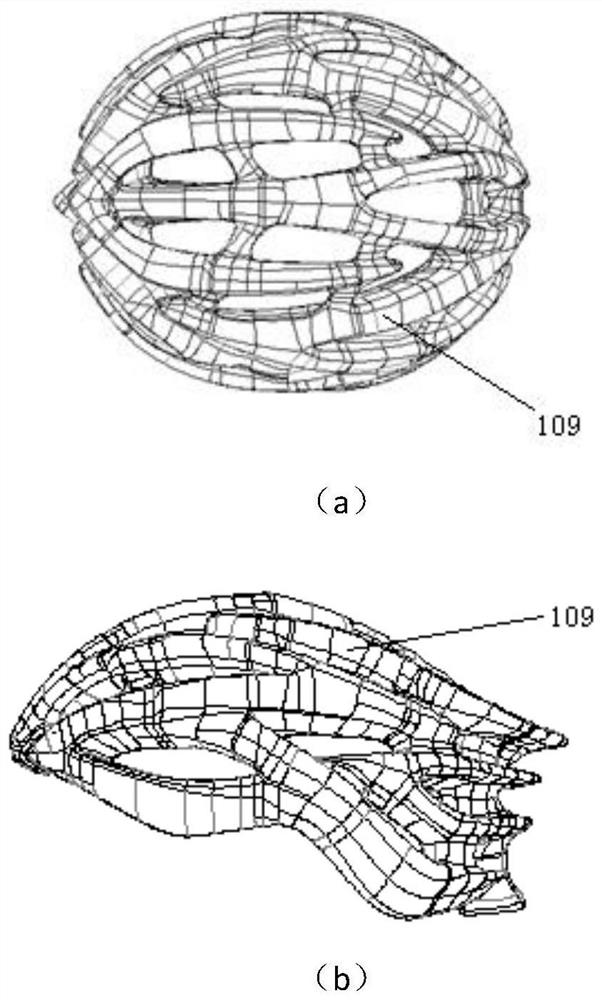

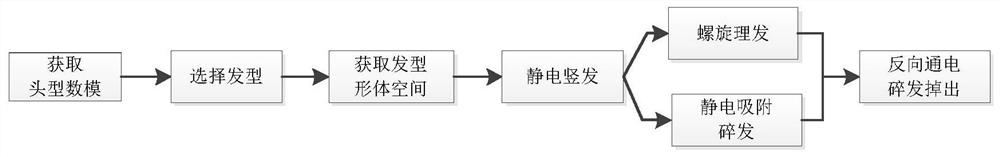

[0026] Such as figure 1 As shown, the electrostatic automatic haircutting system based on the magnetic fluid shaping grid includes a helmet-like shell, an electrostatic generating device 107 and a minimum system 106; The magnetized fluid module 103, the spiral track 105 is located between the housing cover 104 and the magnetic fluid module 103, the housing cover 104 is located at the outermost layer of the helmet-type housing, and is used in conjunction with the hair collector 101; the static electricity generating device 107 is electrically connected to the housing cover 104 Connection can generate static electricity and neutralize static charge. When static electricity is generated, the hair will stand up and the broken hair will be collected. When the charge is neutralized, the broken hair will fall; the cutter assembly 102 and the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com