High-performance ptfe-coated needle-punched felt and preparation method thereof

A high-performance, needle-punched felt technology, applied in the field of needle-punched felt, can solve the problem of low structural strength of PTFE needle-punched felt, and achieve the effect of improving the filtering and dust removal ability, the fixed structure is reasonable and effective, and the use effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

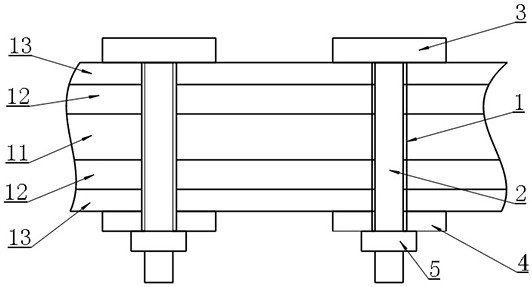

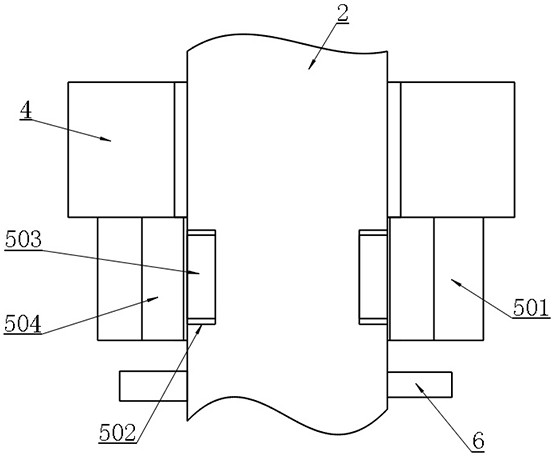

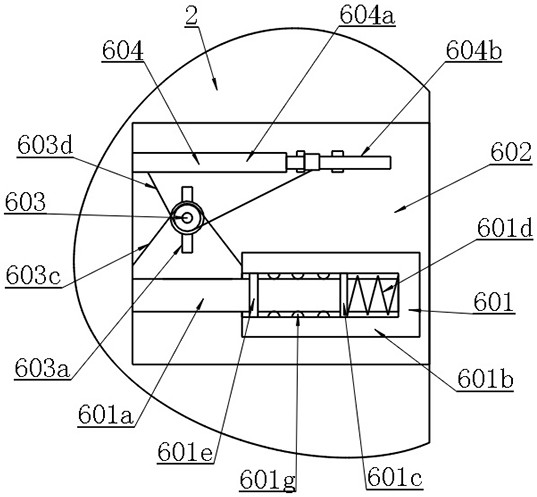

[0027] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Figure 6 As shown, the high-performance PTFE-coated needle-punched felt includes a PTFE net base layer 11, a heat insulation cotton layer 12 arranged on both sides of the PTFE net base layer 11, and a PTFE coating film arranged on the heat insulation cotton layer 12 The layer 13 also includes the socket 1 arranged on the PTFE mesh base layer 11, the heat insulation cotton layer 12 and the PTFE coating layer 13, and inserts the heat conduction column 2 arranged on the socket 1, The fixed heat conduction plate 3 fixedly arranged at one end of the plug-in heat conduction column 2 is sleeved on the insert heat conduction column 2 and clamps the film-coated needle felt together with the fixed heat conduction plate 3 The socketed heat conduction plate 4 is arranged on the plug-in heat conduction column 2 and is used to limit and fix the magnetic force unit 5 of the socket heat conduction plate 4 by means of circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com