A dust-free clean room test console

A test operation table, clean room technology, applied in construction, chemical instruments and methods, building structure, etc., can solve problems such as inconvenient operation of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

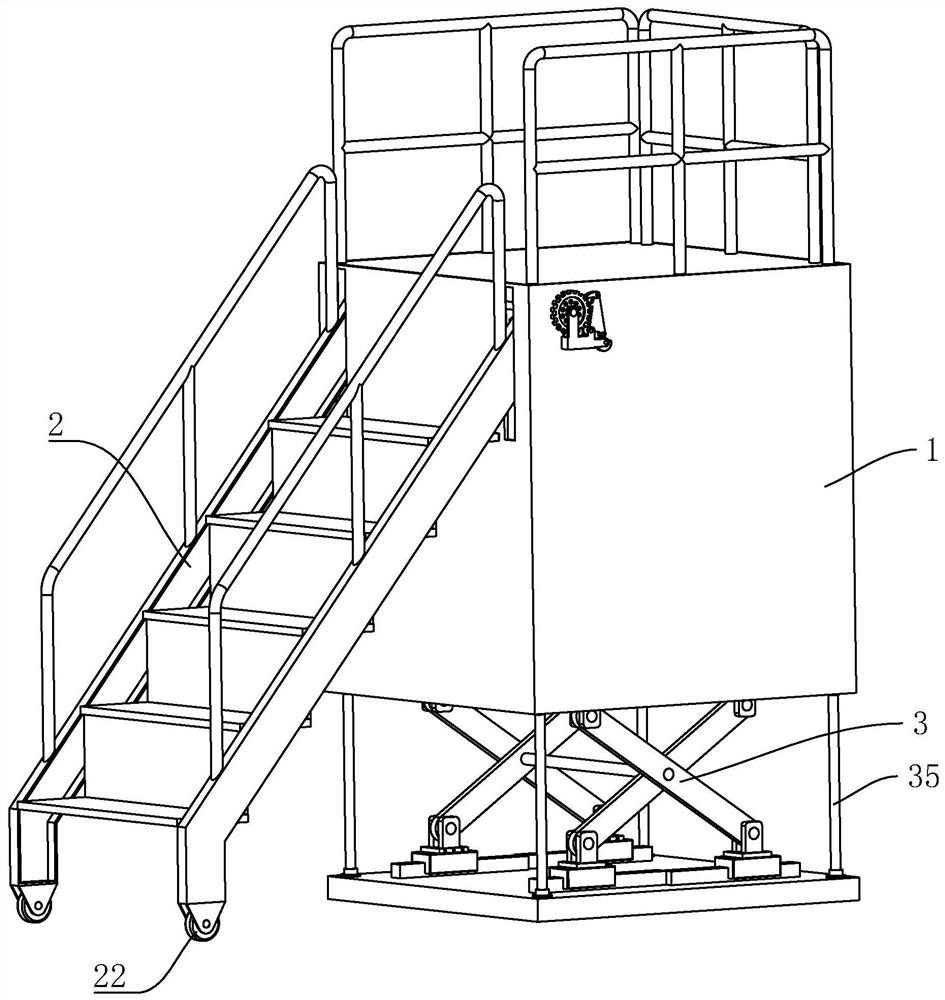

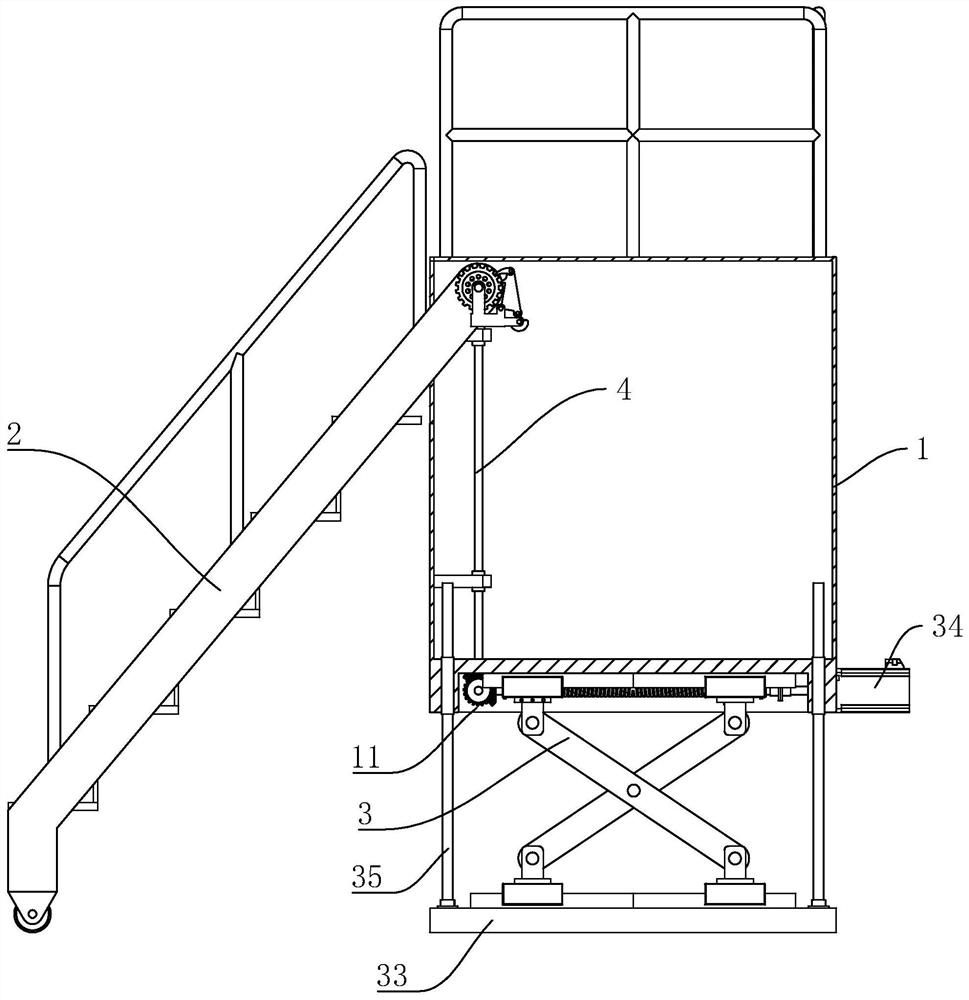

[0046] Embodiment 1: A kind of dust-free clean room test operating platform, such as figure 1 and 2 As shown, a platform 1 is included, and a ladder 2 arranged obliquely is hinged on the platform 1 , and the top of the ladder 2 is hinged to the top edge of the platform 1 . The bottom of the platform 1 is provided with a lifting mechanism 3 for driving the platform 1 up and down, and the platform 1 is also provided with a transmission mechanism 4 for driving the ladder 2 to adjust as the height of the platform 1 rises.

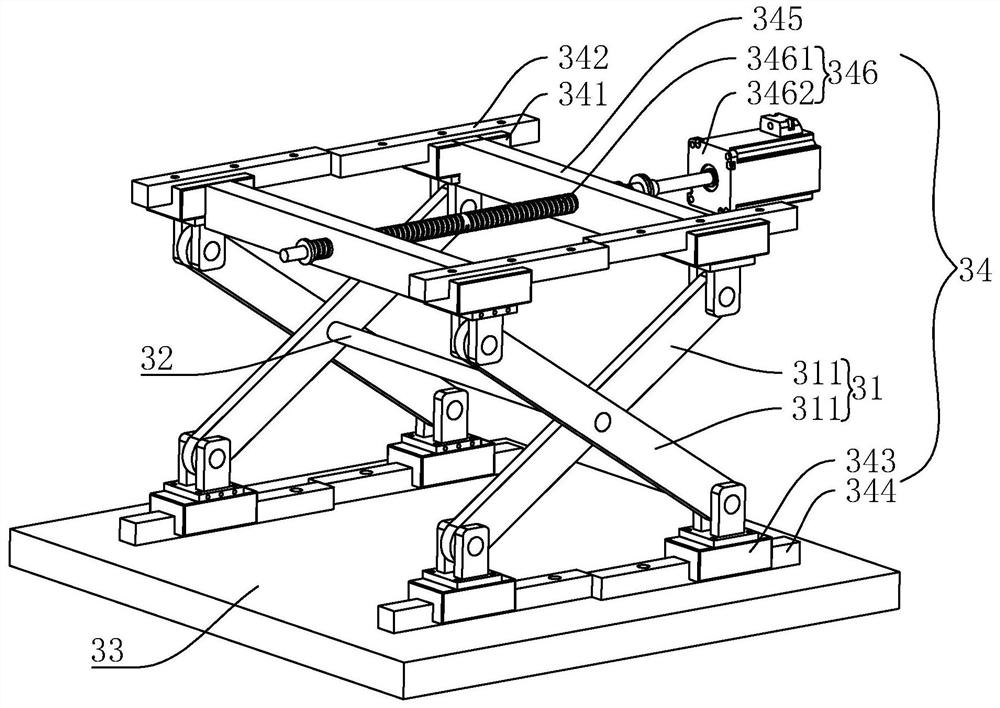

[0047] Such as figure 2 and 3 As shown, the bottom surface of the platform 1 is provided with a receiving tank 11, and the lifting mechanism 3 includes a base plate 33 arranged directly below the platform 1, and two mutually parallel scissor-shaped brackets 31 are arranged between the base plate 33 and the top wall of the receiving tank 11. The bracket 31 is arranged perpendicular to the horizontal plane. The scissor bracket 31 includes two struts 311 arra...

Embodiment 2

[0057] Embodiment 2: A kind of dust-free clean room test operating platform, such as Image 6 As shown, the primary transmission assembly 41 includes a driving bevel gear 413 disposed on the end of the bidirectional threaded rod 3461 facing away from the motor 3462 , and a driven bevel gear 414 meshing with the driving bevel gear 413 is fixedly mounted on the transmission shaft 43 . The motor 3462 drives the two-way threaded rod 3461 to rotate, and the two-way threaded rod 3461 drives the driving bevel gear 413 arranged at its end to rotate, and the driving bevel gear 413 meshes with the driven bevel gear 414 to drive the transmission shaft 43 to rotate.

Embodiment 3

[0058] Embodiment 3: A kind of dust-free clean room test operating platform, such as Figure 7 As shown, the two-stage transmission assembly 42 includes a driving gear 424 arranged at both ends of the transmission shaft 43 and a driven gear 425 at both ends of the hinge shaft 21. A transmission chain 426 is sleeved between the driving gear 424 and the driven gear 425, and the platform 1 ( See figure 1 ) The bottom wall is provided with a through hole for passing through the transmission chain 426 . Transmission shaft 43 is driven by driving assembly 346, and transmission shaft 43 drives driving gear 424 at both ends to rotate while rotating, and driving bevel gear 413 and driven gear 425 are transmitted by transmission chain 426, so just can drive hinge shaft 21 to rotate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap