Heat exchange device

A technology of heat exchange device and heat exchange tube, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., and can solve the problem of low heat exchange efficiency of shell side fluid, low utilization rate of Solve the problems of slow flow rate of process fluid and achieve the effects of simple structure, easy processing and improved heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

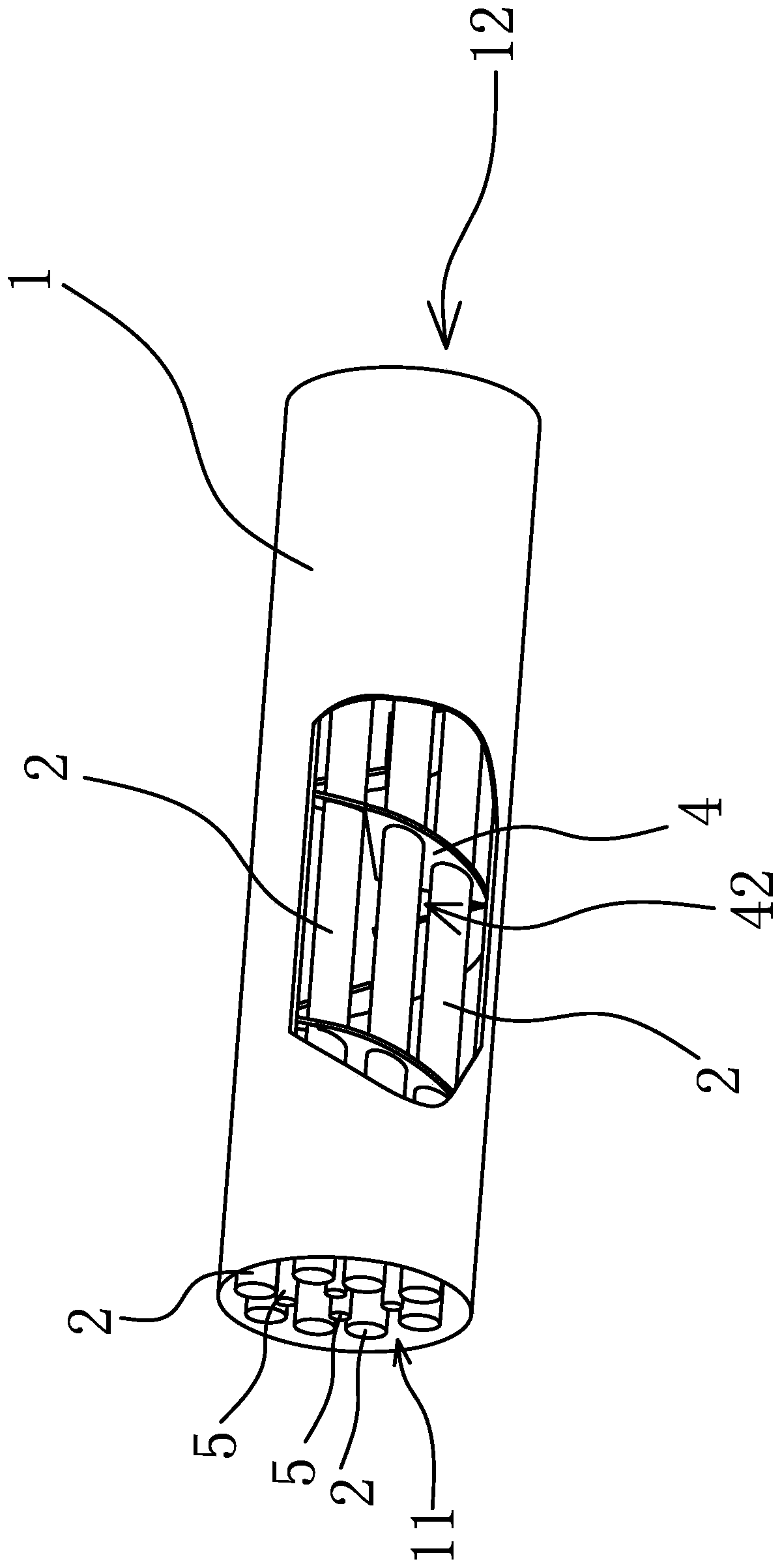

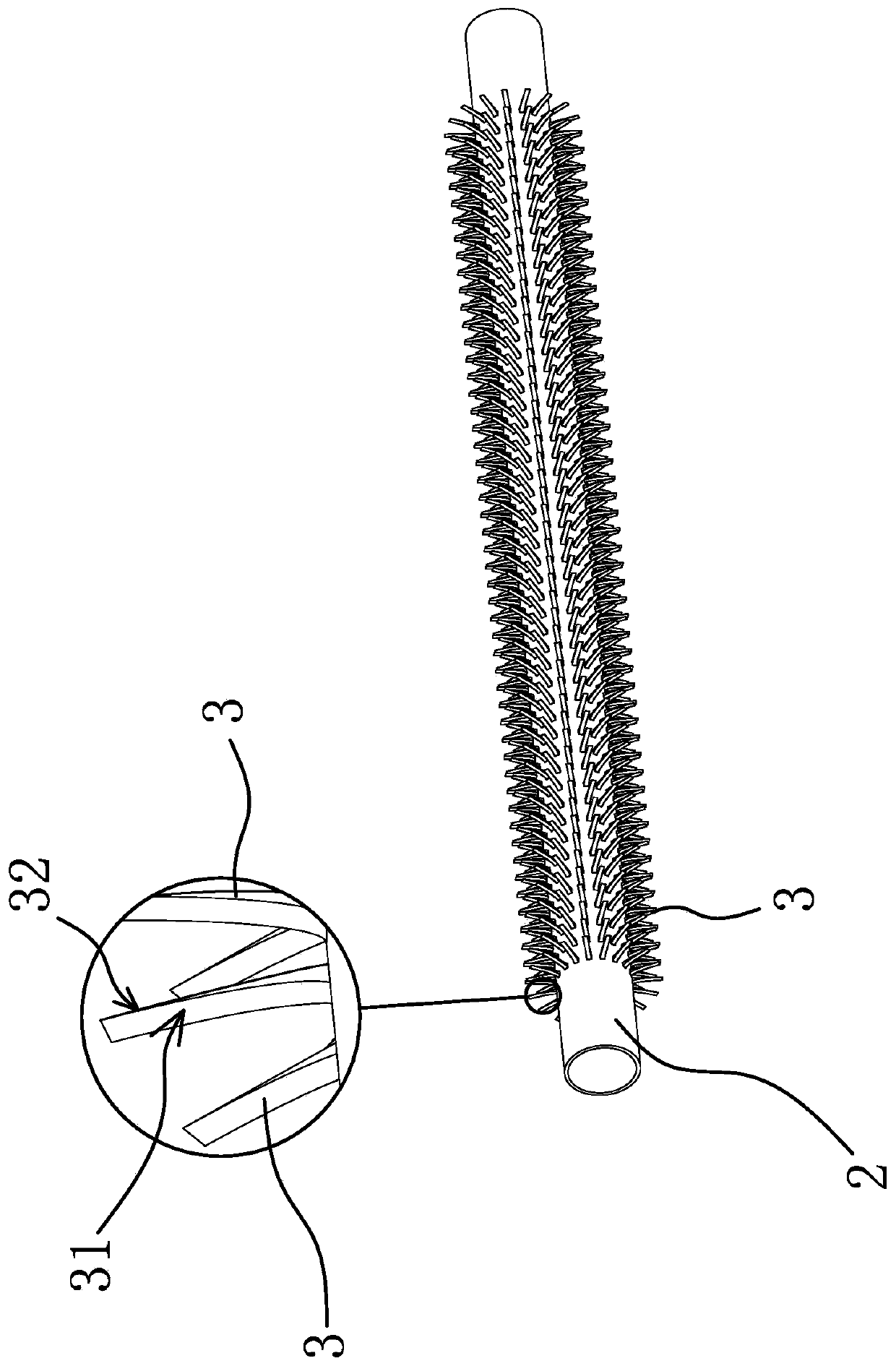

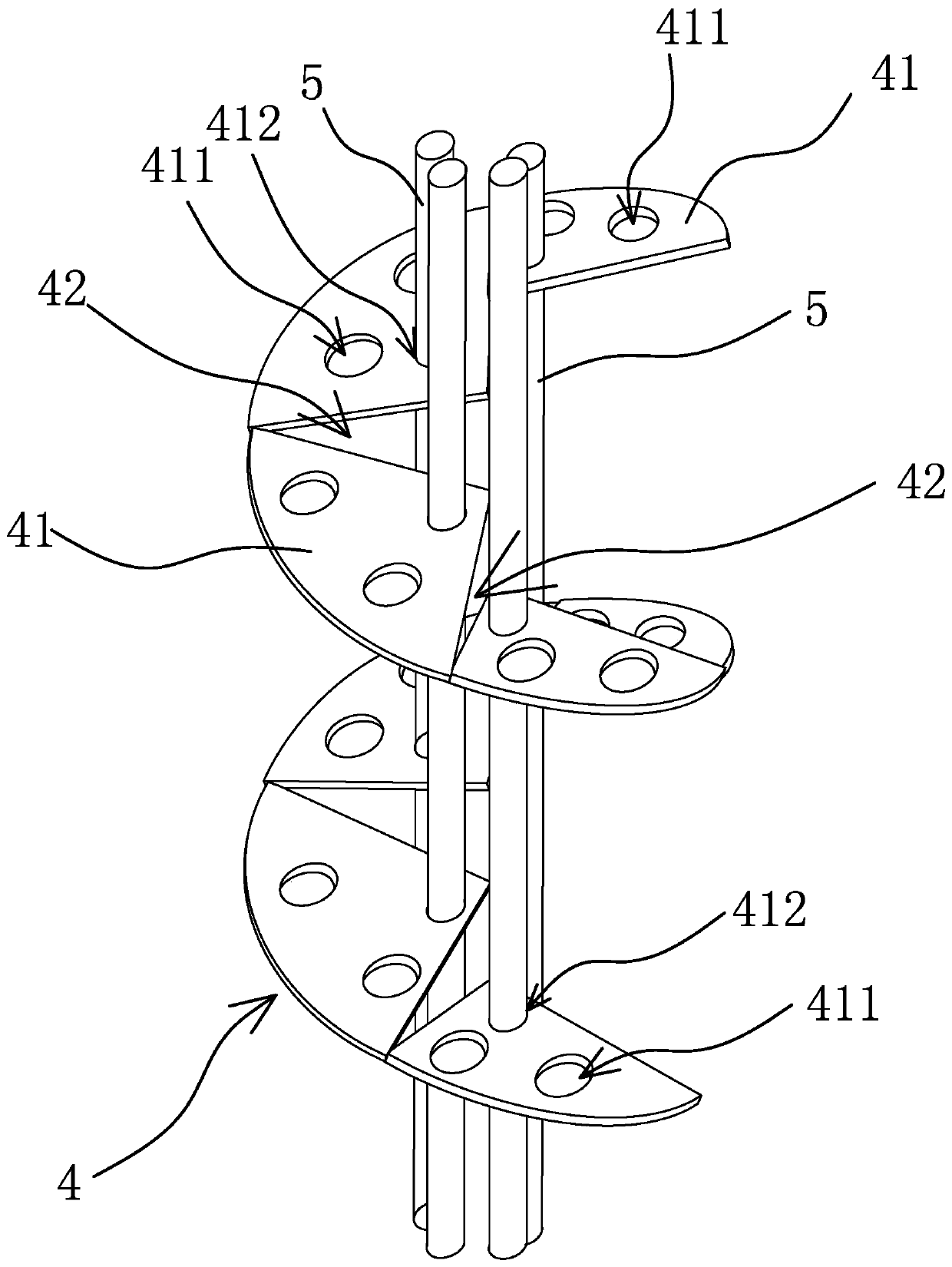

[0028] A heat exchange device such as figure 1 , figure 2 As shown, it includes a shell 1, a baffle plate 4 and a number of heat exchange tubes 2, wherein the shell 1 is cylindrical, one end of the shell 1 has a shell-side fluid inlet 11 and the other end has a shell-side fluid outlet 12, folded The flow plate 4 is spirally arranged in the casing 1 along the length direction of the casing 1, and the heat exchange tube 2 is also arranged in the casing 1 along the length direction of the casing 1. Fins 3, fins 3 have guide surfaces 31 that keep the shell-side fluid away from the heat pipe and form disturbances, and the baffle plate 4 is provided with a plurality of baffles at intervals along its extending direction for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap