PCB marking printing quality detection method based on deep learning

A PCB board and deep learning technology, applied in image data processing, image enhancement, instruments, etc., can solve the problems of high detection cost, detection accuracy cannot be effectively guaranteed, and manual detection efficiency is low, achieving high recognition accuracy, anti- Strong ability to resist background interference and light conditions, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

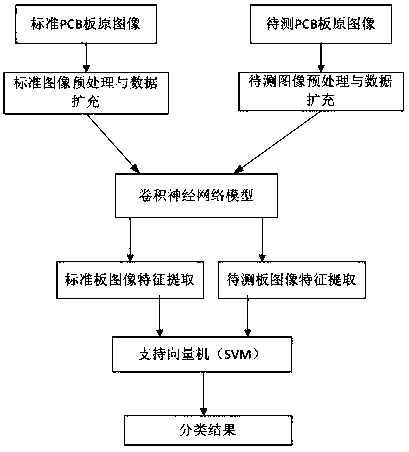

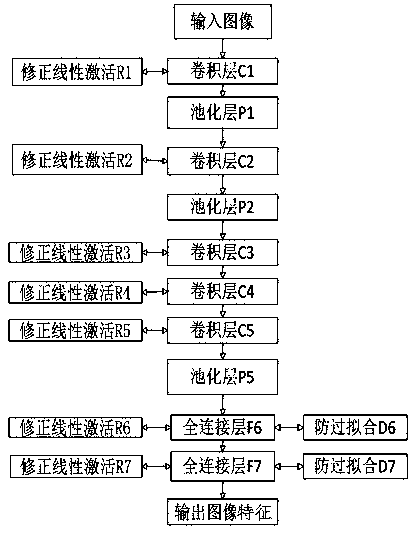

[0027] refer to Figure 1-3 , a method for detecting the printing quality of printed circuit board labels based on deep learning, including the following steps:

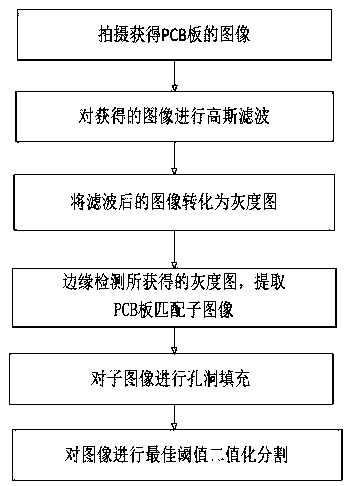

[0028] (1) Preprocessing the standard PCB board image: the specific sub-steps are as follows:

[0029] Step 1.1), select the PCB board without silk screen defects as the standard PCB board, use the color camera to capture the standard PCB board image, and perform Gaussian filtering on the standard PCB board image to obtain the filtered image;

[0030] Step 1.2), converting the filtered image into a grayscale image to obtain a filtered grayscale image;

[0031] Step 1.3), obtain the boundary of the PCB board matching area in the grayscale image through edge detection, and obtain the PCB board matching sub-image from the filtered image according to the boundary;

[0032] Step 1.4), use the hole filling algorithm to fill the image of the pad and other interference information data;

[0033] Step 1.5), use the Otsu al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com