Vibratory picking and harvesting device for high spindle tree shaped apple trees

A technology for picking and harvesting apple trees, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of lack of public practicability, inability to achieve the use effect, and low harvesting efficiency, and achieve high efficiency and high quality apples Picking and harvesting, saving working time of fruit growers, and high harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention is designed based on the characteristics of a tall spindle tree-shaped fruit tree with simple structure, few branching stages, and straight trunk. By vibrating the trunk of the fruit tree instead of picking by human hands or manipulators, the whole process of apple picking and harvesting is fully automated.

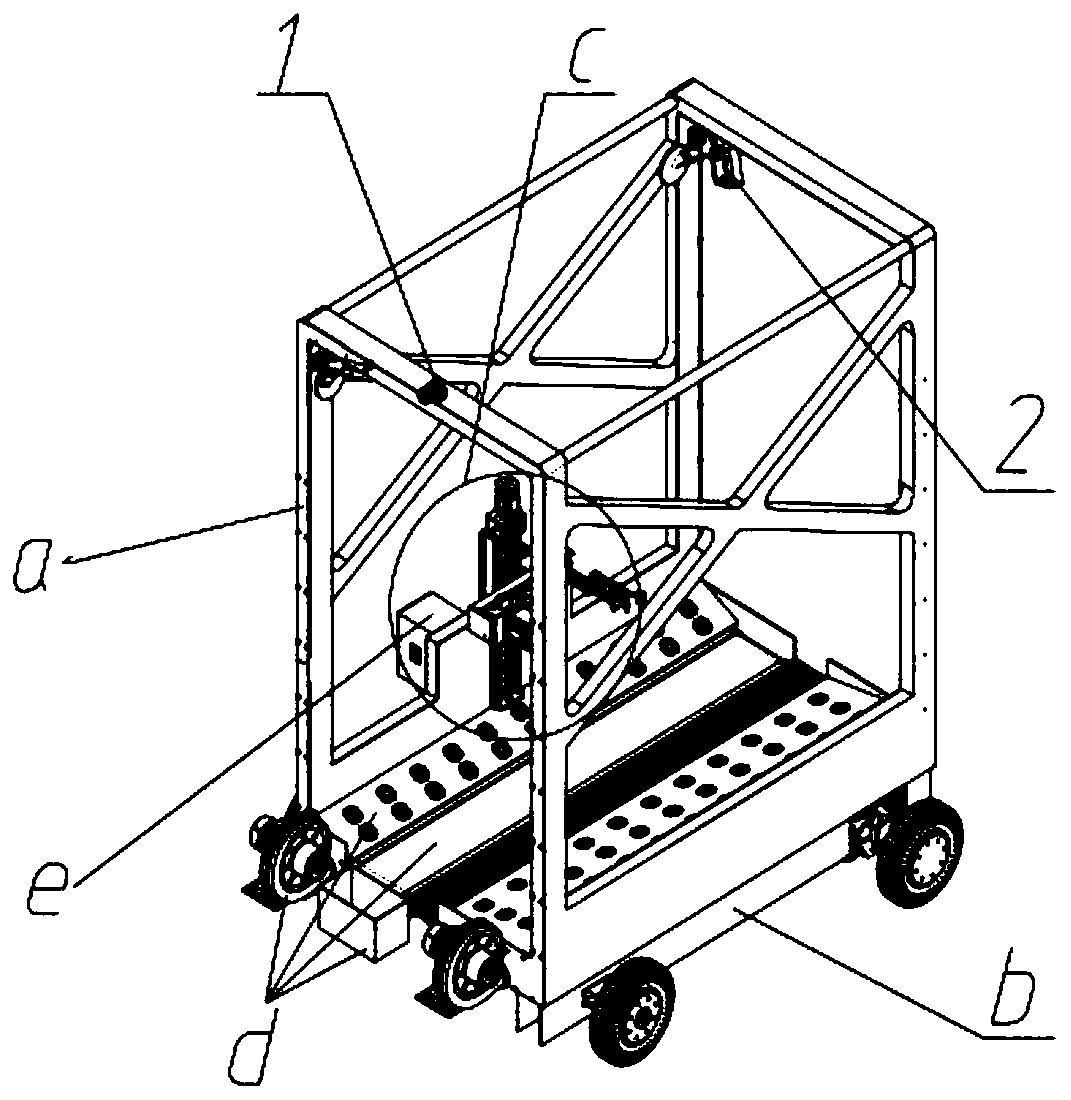

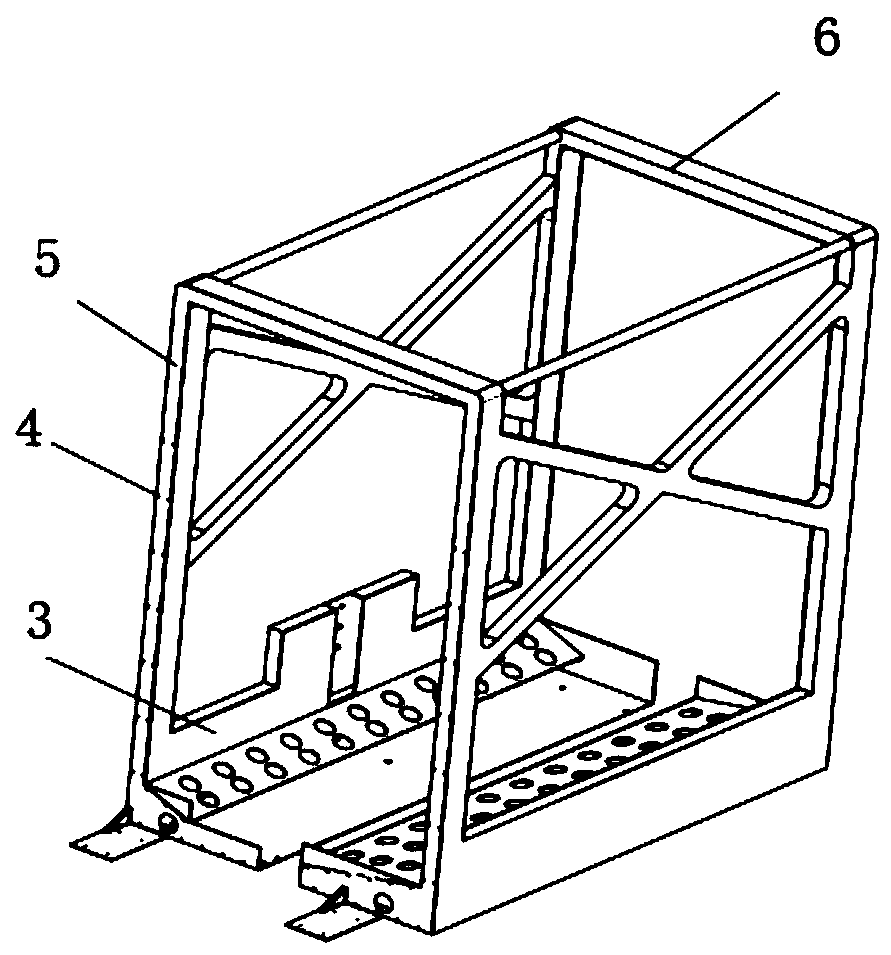

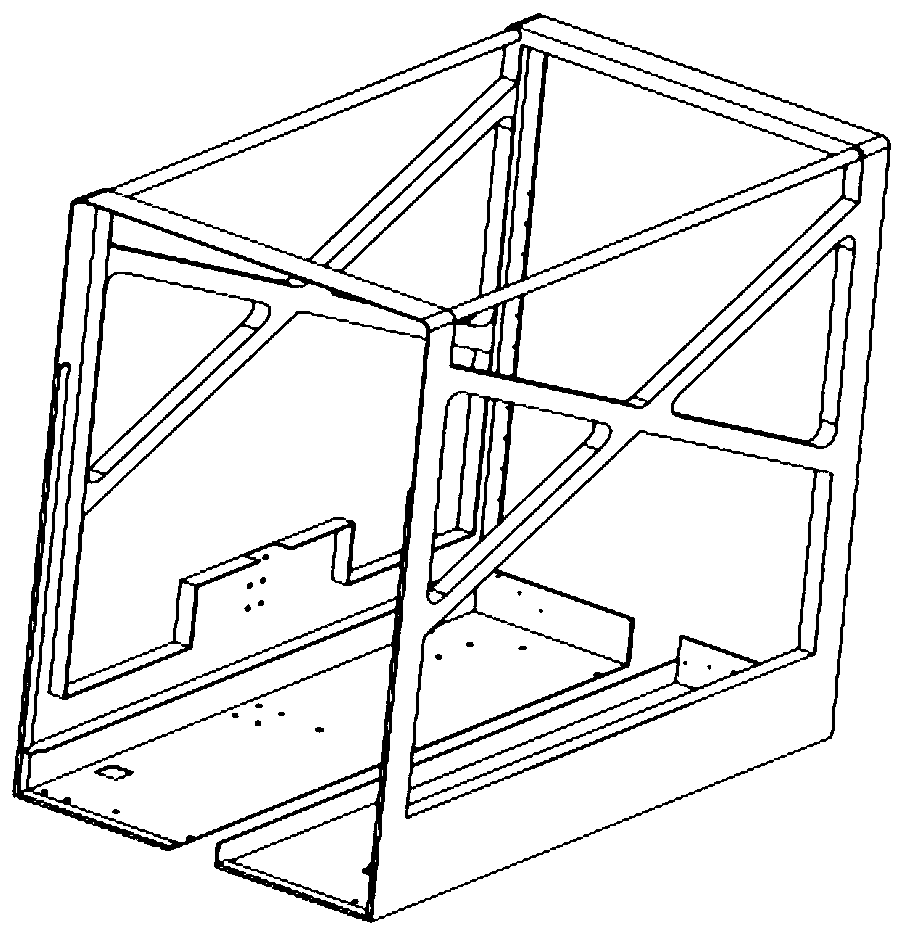

[0040] figure 1 It is shown that the present invention consists of a gantry car body a, a walking device b, a vibrating tree-shaking device c, a buffer collection device d, an electric control cabinet e, a laser scanner 1 and a binocular vision positioning camera 2.

[0041] The gantry car body a is the carrier of the whole device, providing support for each part of the structure; the walking device b can drive the whole device to walk in the orchard for picking operations; the vibration tree shaking device c can vibrate the trunks of fruit trees of different heights to make them mature The apple falls; the buffer collection device d can slow down the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap