Multistage crusher capable of achieving screening

A crusher, a first-class technology, applied in the direction of grain processing, etc., can solve the problems of poor continuous crushing, production interruption, over-crushing, etc., and achieve the effect of convenient disassembly and transportation, avoiding over-crushing, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

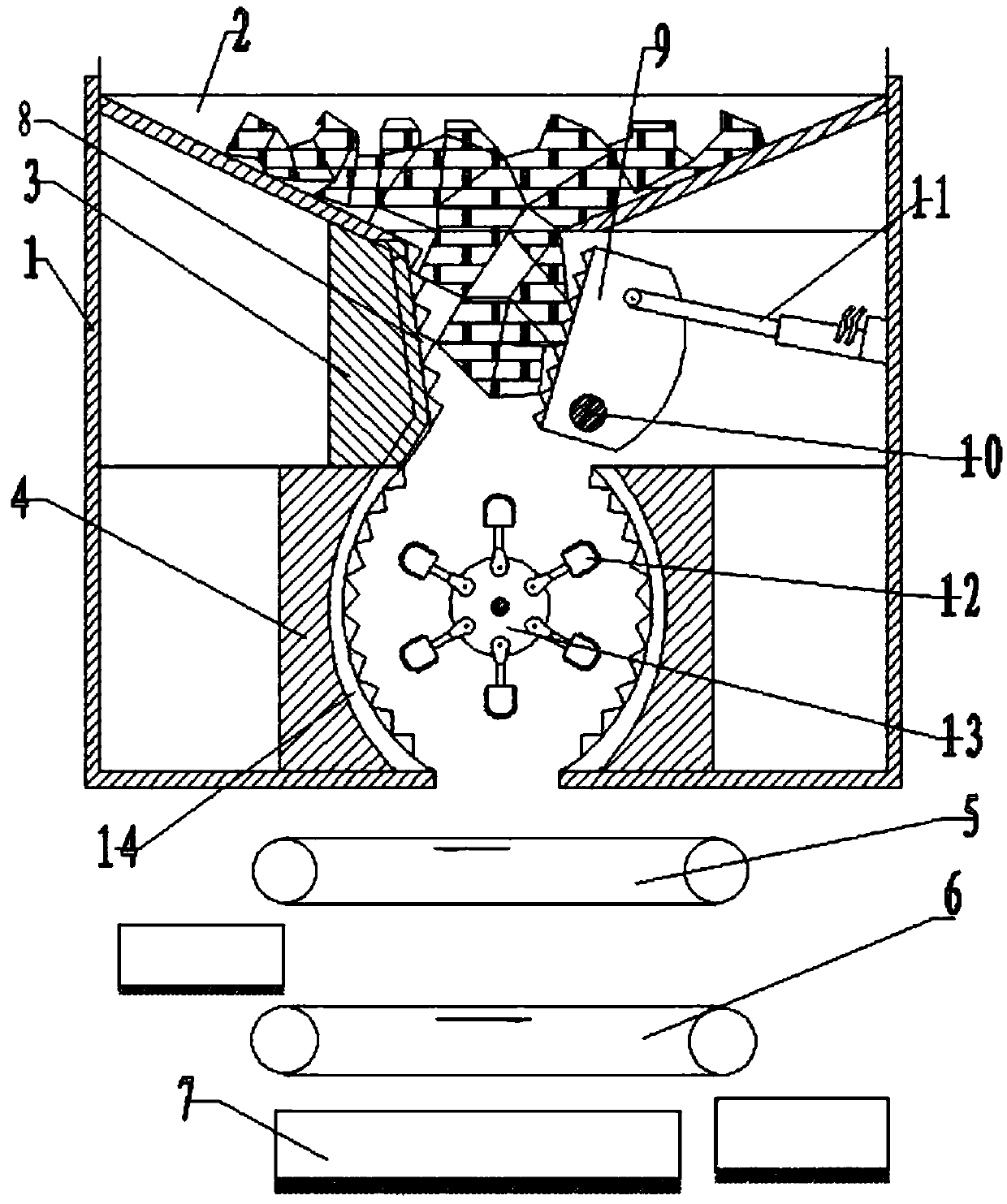

[0009] Such as figure 1 As shown, a multi-stage crushing crusher that can be screened includes a crusher body 1, a collection tank 2, a primary crusher 3, a secondary crusher 4, a large coal block filter 5, and a medium coal block filter 6 And the small coal block collection tank 7, the top of the crusher body 1 is the collection tank 2, the coal block outlet in the collection tank 2 is connected with the primary crusher 3, the coal block directly enters the primary crusher 3 for crushing, and the secondary crusher 4. Below the primary crusher 3, the coals crushed by the primary crusher 3 leak into the secondary crusher 4, where they are further crushed in the secondary crusher 4, and the large coal block screen 5 is crushed in the secondary Below the coal outlet of the machine 4, the medium-sized coal block screener 6 is below the large-sized coal block screener 5, and the coal block leaked from the large-sized coal block screener 5 enters the medium-sized coal block screener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com