2000 MPa-grade bridge cable galvanized steel wire and preparation method thereof

A technology of galvanized steel wire and manufacturing method, which is applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem of low pass rate of torsion, and achieve the effect of avoiding rapid expansion and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

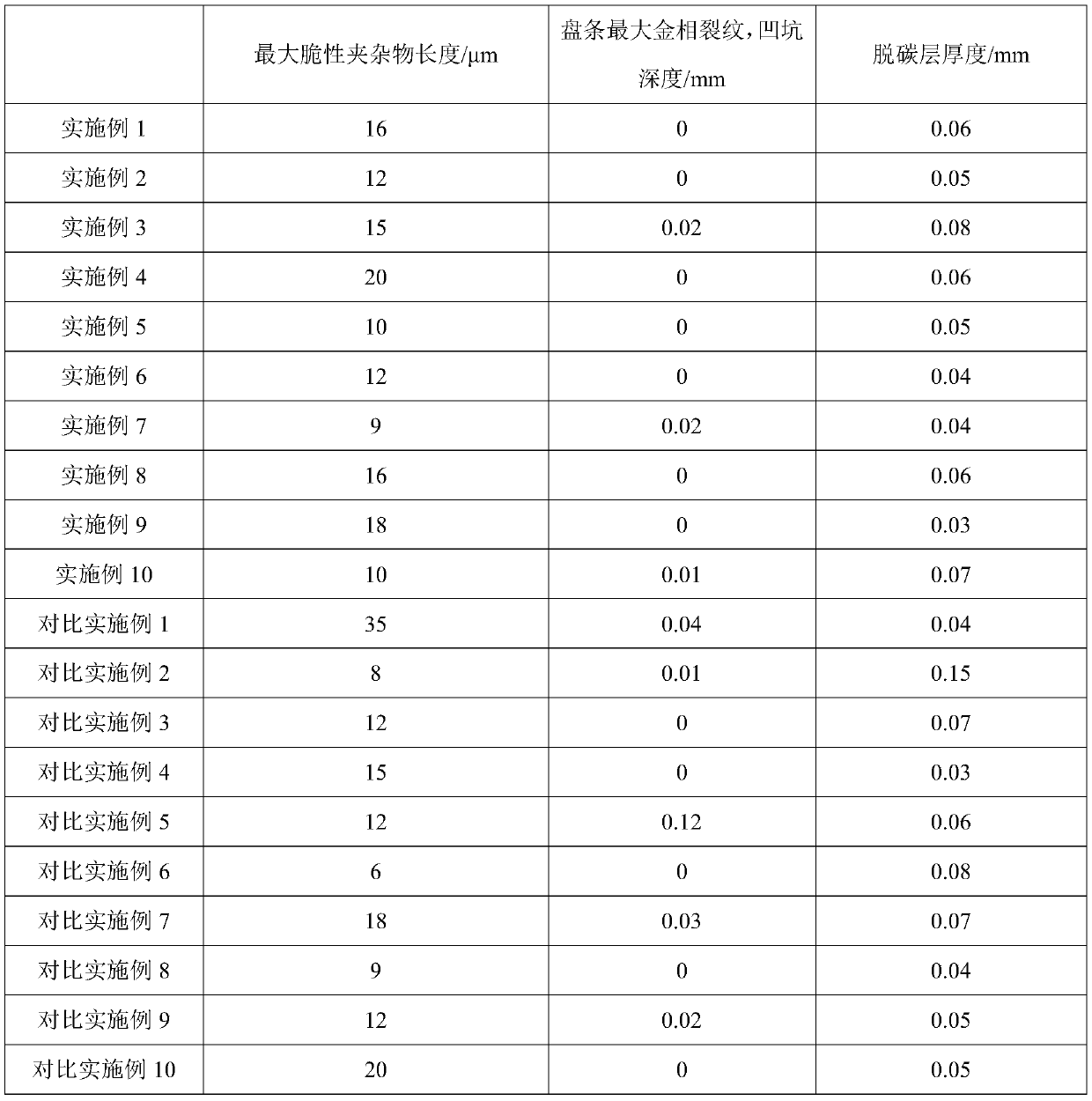

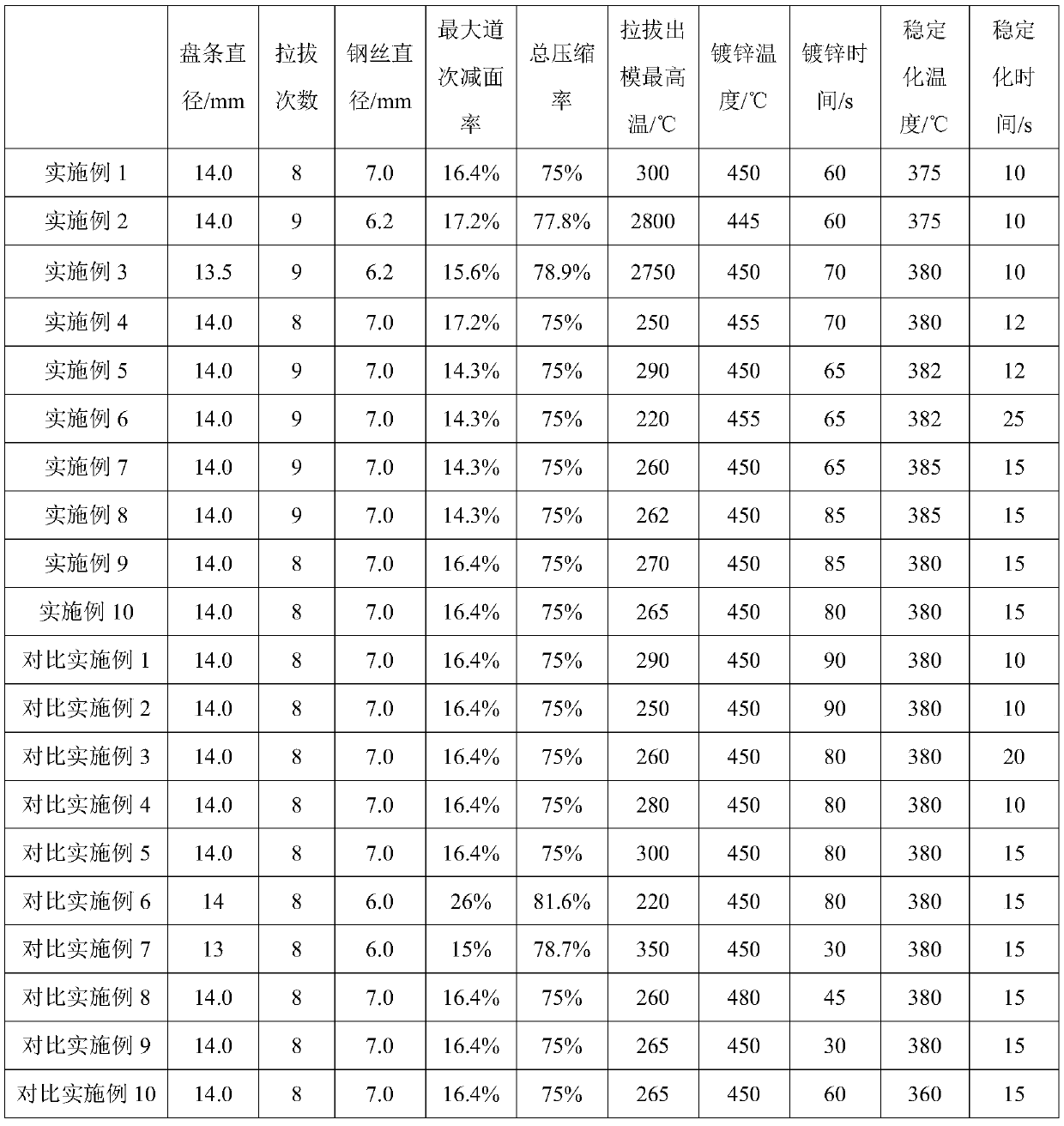

[0045] The 2000MPa bridge cable galvanized steel wire and its manufacturing method in the present invention will be further described below.

[0046] In the present invention, the chemical composition of the 2000MPa bridge cable galvanized steel wire includes: C0.88-0.94%, Si 1.05-1.35%, Mn 0.40-0.50%, Cr 0.25-0.35%, Cu≤0.07%, and the remaining The amount is Fe and unavoidable impurity elements, and the chemical composition also includes any one or more of B 0.0005-0.0015%, Nb 0.01-0.03% and Mo0.01-0.03%.

[0047] The above-mentioned manufacturing method of 2000MPa level bridge cable galvanized steel wire includes selection of wire rod, wire rod pickling, phosphating, wire drawing, galvanizing and stabilization process. The production process is detailed as follows:

[0048] 1. Selection of wire rod

[0049] The wire rod is selected according to the chemical composition, surface quality and inclusion requirements required by the present invention.

[0050] The chemical compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com