A socket type radiator

A radiator, socket-type technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of low production efficiency, long labor hours, long production process routes, etc., to improve contact The effect of improving the connection reliability and improving the performance of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

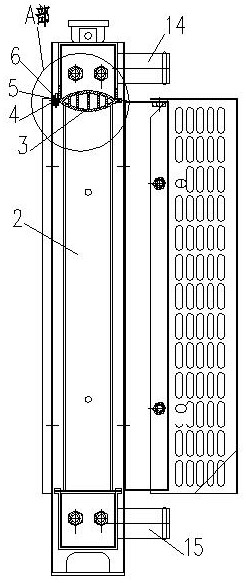

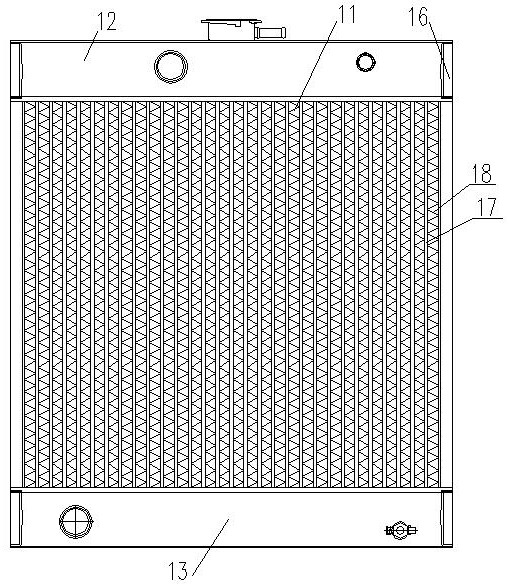

[0021] A socket-type radiator, comprising a core assembly 1, the left and right sides of the core assembly 1 are respectively provided with side plates 2; the core assembly 1 includes a core 11, and a 11 the upper water chamber 12 on the upper part and the lower water chamber 13 at the lower part of the core 11;

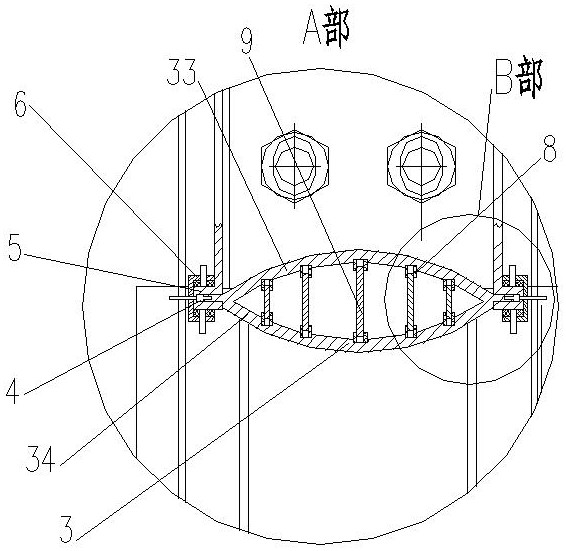

[0022] The upper and lower ends of the core 11 are respectively provided with elastic clamping plates 3, the two sides of the lower end of the upper water chamber 12 and the upper end of the lower water chamber 13 are respectively provided with socket slots 4, and the clamping plates 3 are clamped into the In the socket socket 4;

[0023] The upper water chamber 12 and the lower water chamber 13 have certain elasticity;

[0024] The outer surface of the part of the socket slot 4 forms a card platform 5 in the form of a step structure, and the card platform 5 is provided with a snap ring 6, and the snap ring 6 is provided with a threaded hole 61, and the snap ring 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com