Super-bubble biochemical gas cap segregation apparatus and application thereof

A separation device and gas cap technology, applied in application, fish farming, animal husbandry, etc., can solve the problems of high cost and poor effect, and achieve more economical and cost-effective, simple structure, and strong ammonia nitrogen residue processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

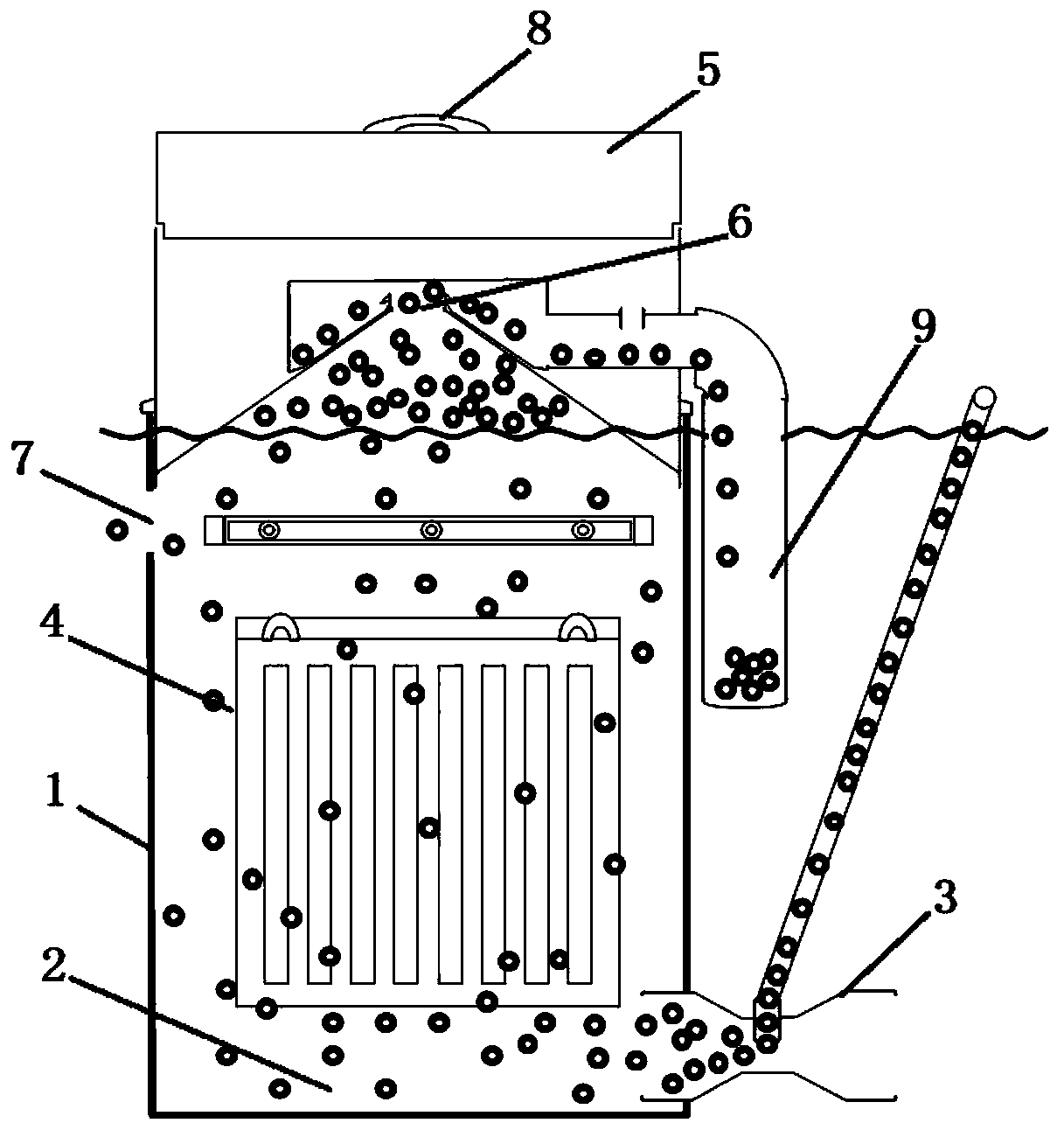

[0031] This embodiment provides a superfoam biochemical gas cap separation device, comprising a container 1, a superbubble mechanism arranged at the bottom of the container 1, a gas cap mechanism arranged above the container 1, and a gas cap mechanism arranged between the superbubble mechanism and the gas cap mechanism Biochemical mechanism, described superfoam mechanism comprises the water tank 2 that is arranged on the bottom of container 1, and the nozzle 3 that communicates with water tank 2, and described biochemical mechanism includes the carrier that is arranged on water tank 2, is arranged on carrier The biochemical filter material 4 on the top, and the beneficial bacteria distributed on the biochemical filter material 4, the air cap mechanism includes an air cap 5 arranged above the container 1, and an air cap is formed between the gas cap 5 and the biochemical filter material 4. The top chamber, the top of the air cap chamber is provided with an air cap overflow port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com