A CNC machine tool machining center fixture

A technology of machining centers and CNC machine tools, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as unfavorable production and development of enterprises, affecting processing accuracy, complicated clamping steps, etc., to achieve easy disassembly and assembly operations. , The effect of high clamping stability and reducing the scrap rate of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

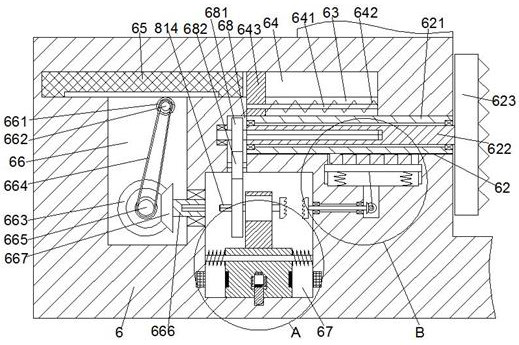

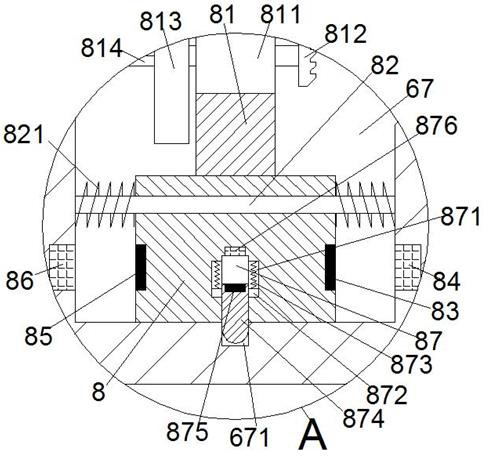

[0028] When the workpiece needs to be clamped, the third electromagnetic coil device 876 is powered on, so that the third electromagnetic coil device 876 and the third magnetic block 875 generate an attractive force, and then the lock slider 874 drives the limit block 872 to overcome the top of the fourth spring 873. The pressure slides upward until the lock slider 874 completely slides out of the lock groove 671. At the same time, the first electromagnetic coil device 86 is controlled to be powered on, so that the first electromagnetic coil device 86 and the first magnetic block 85 generate an attractive force, and then the mobile slide The table 8 slides to the leftmost position in the second inner cavity 67 to the greatest extent against the pressing force of the third spring 821 on the left side. At this time, the second spline shaft 814 is power-fitted with the second inner spline rotary sleeve 666. , at the same time, make the fourth gear 813 and the second gear 682 in a ...

Embodiment 2

[0030] When the workpiece needs to be rotated and processed, the mobile slide table 8 is kept in the initial state, and at the same time, the lock slider 874 and the lock groove 671 are in a locked connection state and the fourth gear 813 is in a meshed connection state with the second gear 682, Then, the rotation of the fourth gear 813 is controlled by the drive motor 811, and then the fourth gear 813 drives the second gear 682 and the first gear 681 to rotate. At this time, the first gear 681 drives the first spline shaft 624 and the first inner When the splined rotating sleeve 622 rotates, the first inner splined rotating sleeve 622 drives the second clamping disc 623 to rotate, and then the workpiece between the second clamping disc 623 and the first clamping disc 611 is driven to rotate.

Embodiment 3

[0032] When the workpiece needs to be taken out, the second electromagnetic coil device 84 is controlled to be powered on, so that the second electromagnetic coil device 84 and the second magnetic block 83 generate an attractive force, and then the movable slide table 8 overcomes the pressing force of the third spring 821 on the right side to the maximum extent. Slide to the rightmost position in the second inner cavity 67. At this time, the second connecting toothed plate 812 on the right side of the support platform 81 is connected with the first connecting toothed plate 6962 in power fit, and at the same time, the left side of the supporting platform 81 The fourth gear 813 is disengaged from the second gear 682, and then drives the second connecting toothed plate 812 to rotate through the driving motor 811, and then the second connecting toothed plate 812 drives the first connecting toothed plate 6962, the rotating shaft 696 and the fourth cone. The gear 6961 rotates. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com