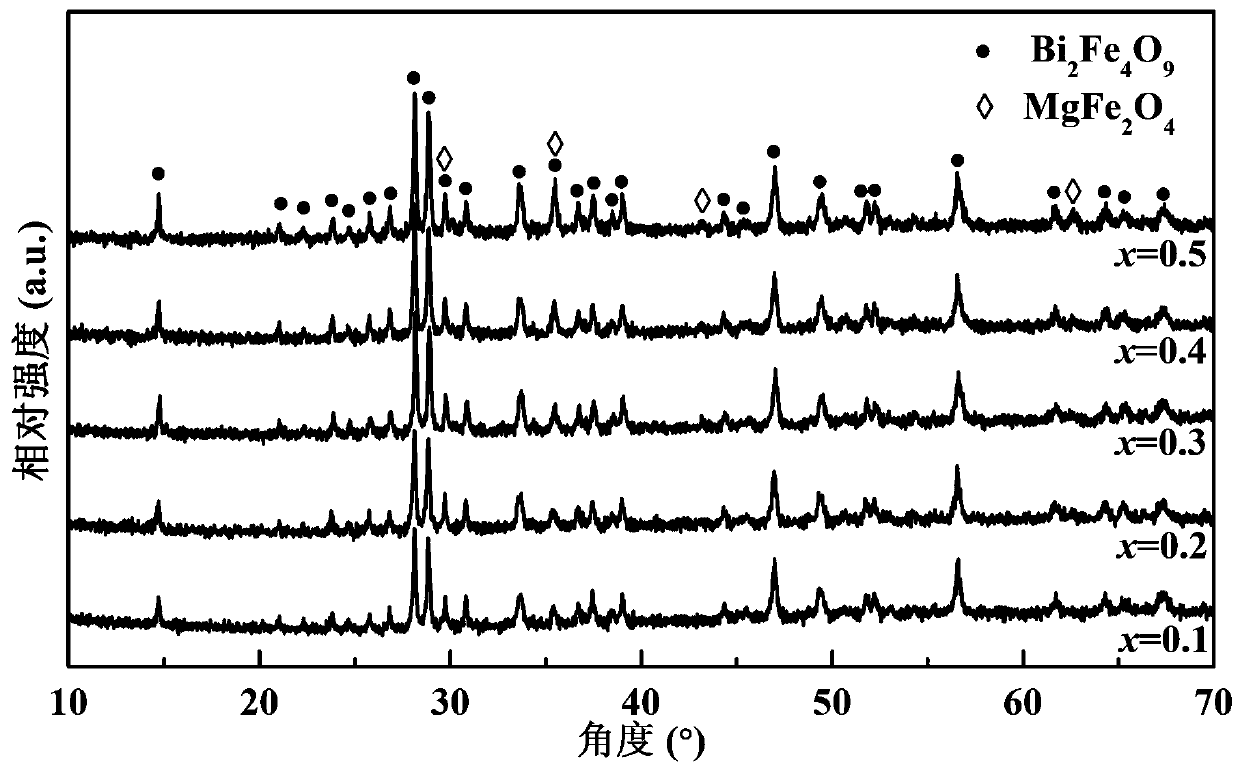

Bi2Fe4O9-MgFe2O4 composite ceramic and preparation method thereof

A technology of bi2fe4o9-mgfe2o4, bi2fe4o9-xmgfe2o9, which is applied in the field of information functional material preparation, can solve the problems such as no records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

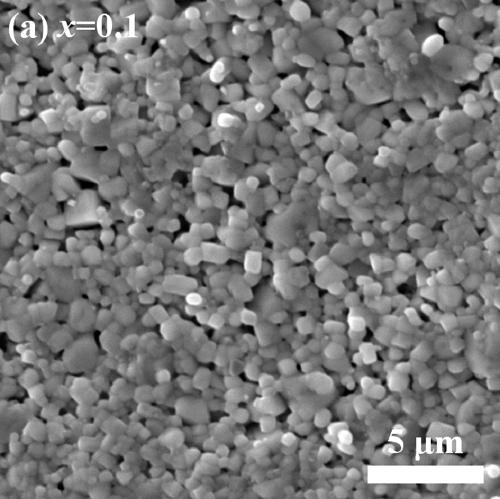

[0025] A Bi 2 Fe 4 o 9 -MgFe 2 o 4 Composite ceramics, the chemical composition of the composite ceramics is expressed as: (1-x) Bi 2 Fe 4 o 9 -xMgFe 2 o 9 , (x=0.1), the composite ceramic is made by the following method:

[0026] 1) Weigh 0.081mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.036mol of Fe(NO 3 ) 3 9H 2 O and 0.018mol Bi(NO 3 ) 3 ·5H 2 O, was dissolved in aqueous citric acid solution under constant stirring to obtain transparent Bi 2 Fe 4 o 9 solution;

[0027]2) Weigh 0.0045mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.002mol of Fe(NO 3 ) 3 9H 2 O and 0.001mol MgCO 3 , was added to aqueous citric acid solution under c...

Embodiment 2

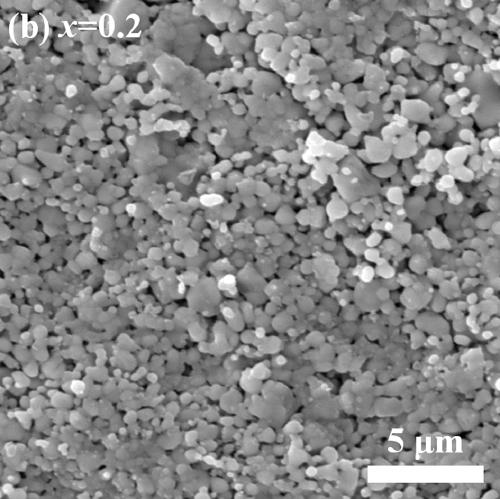

[0031] A Bi 2 Fe 4 o 9 -MgFe 2 o 4 Composite ceramics, the chemical composition of the composite ceramics is expressed as: (1-x) Bi 2 Fe 4 o 9 -xMgFe 2 o 9 , (x=0.2); The composite ceramic is made by the following method:

[0032] 1) Weigh 0.072mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.032mol of Fe(NO 3 ) 3 9H 2 O and 0.016mol Bi(NO 3 ) 3 ·5H 2 O, was dissolved in aqueous citric acid solution under constant stirring to obtain transparent Bi 2 Fe 4 o 9 solution;

[0033] 2) Weigh 0.009mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.004mol of Fe(NO 3 ) 3 9H 2 O and 0.002mol MgCO 3 , and added to the aqueous citric acid solution und...

Embodiment 3

[0036] A Bi 2 Fe 4 o 9 -MgFe 2 o 4 Composite ceramics, the chemical composition of the composite ceramics is expressed as: (1-x) Bi 2 Fe 4 o 9 -xMgFe 2 o 9 , (x=0.3); This composite ceramic is made by the following method:

[0037] 1) Weigh 0.063mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.028mol of Fe(NO 3 ) 3 9H 2 O and 0.014mol Bi(NO 3 ) 3 ·5H 2 O, was dissolved in aqueous citric acid solution under constant stirring to obtain transparent Bi 2 Fe 4 o 9 solution;

[0038] 2) Weigh 0.0135mol of citric acid monohydrate at room temperature and pour it into a beaker with a volume of 100ml, then add 30mL of deionized water, stir to obtain a transparent citric acid aqueous solution, and then weigh 0.006mol of Fe(NO 3 ) 3 9H 2 O and 0.003molMgCO 3 , and added to the aqueous citric acid solution un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com