A kind of graphene porous fiber and continuous preparation method thereof

A porous fiber and graphene technology, applied in the field of fibers, can solve the problems of high temperature, limited preparation methods of graphene porous fibers, and difficulty in continuous preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of continuous preparation method of graphene porous fiber, concrete steps are:

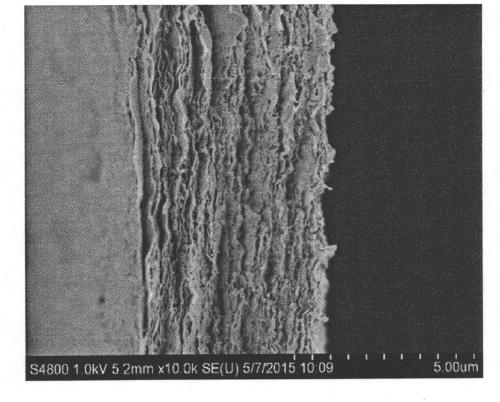

[0025] A coil of copper wire with a diameter of 5 μm and a length of 1000 meters was selected. The copper wire is pulled out continuously and immersed in a lithium perchlorate solution of graphene oxide, wherein the mass percentage of lithium perchlorate is 0.5%, and the mass percentage of graphene oxide is 0.1%. Then electrochemically plate graphene on the copper wire surface by a three-electrode system, the working electrode of the three-electrode system is a copper wire, the counter electrode is a platinum wire with a length of 1 meter, the reference electrode is a silver / silver chloride electrode, and the platinum The wire and the copper wire are arranged in parallel, and the distance between them is 2mm. The silver / silver chloride electrode was placed in a lithium perchlorate solution of graphene oxide at the midpoint of the length of the platinum wire, close to but not in cont...

Embodiment 2

[0027] A kind of continuous preparation method of graphene porous fiber, concrete steps are:

[0028] A coil of copper wire with a diameter of 5 μm and a length of 1000 meters was selected. The copper wire is pulled out continuously and immersed in a lithium perchlorate solution of graphene oxide, wherein the mass percentage of lithium perchlorate is 0.2%, and the mass percentage of graphene oxide is 1%. Then electrochemically plate graphene on the copper wire surface by a three-electrode system, the working electrode of the three-electrode system is a copper wire, the counter electrode is a platinum wire with a length of 1 meter, the reference electrode is a silver / silver chloride electrode, and the platinum The wire and the copper wire are arranged in parallel, and the distance between them is 2mm. The silver / silver chloride electrode was placed in a lithium perchlorate solution of graphene oxide at the midpoint of the length of the platinum wire, close to but not in contac...

Embodiment 3

[0030] A kind of continuous preparation method of graphene porous fiber, concrete steps are:

[0031] A coil of copper wire with a diameter of 20 μm is selected and the length is 1000 meters. The copper wire is pulled out continuously and immersed in the hydrochloric acid solution of graphene oxide, wherein the mass percentage of hydrochloric acid is 0.6%, and the mass percentage of graphene oxide is 1%. Then electrochemically plate graphene on the copper wire surface by a three-electrode system, the working electrode of the three-electrode system is a copper wire, the counter electrode is a platinum wire with a length of 1 meter, the reference electrode is a silver / silver chloride electrode, and the platinum The wire and the copper wire are arranged in parallel, and the distance between them is 2mm. The silver / silver chloride electrode is placed in the hydrochloric acid solution of graphene oxide, and its placement position is at the middle point of the length of the platinu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com