6XXX series aluminium alloy material containing high manganese and chromium for automobile body and preparation method of

A technology of aluminum alloy material and car body, which is applied in the field of high manganese-chromium-containing 6XXX series aluminum alloy material for automobile body and its preparation field, can solve problems such as inability to meet the requirements, and achieve the effect of easy folding and forming and avoiding crushing test rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

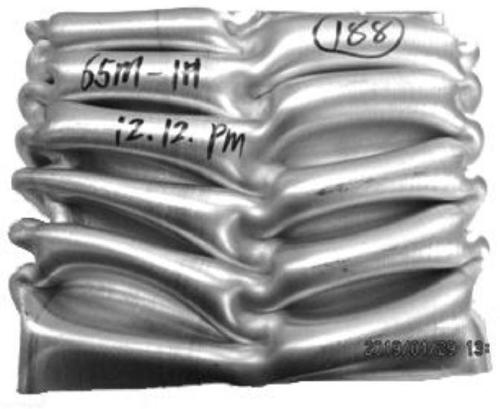

Image

Examples

preparation example Construction

[0026] The invention provides a technical solution: high-manganese-chromium-containing 6XXX series aluminum alloy material for automobile body and its preparation method, including 0.55-0.65% Si, <0.3% Fe, <0.15-0.25% Cu, 0.4 -0.5% Mn, 0.6-0.7% Mg, 0.15-0.2% Cr, <0.15% Zn, 0.02-0.05% Ti, 0.6-0.7% Mn+Cr inevitable impurity elements each <0.05% , and the total amount of unavoidable impurity elements is less than 0.15%, and the balance is aluminum.

[0027] Described preparation method comprises:

[0028] Preparation of materials: Prepare with pure metal aluminum, magnesium, copper, Al-Si master alloy, chromium agent, manganese agent, titanium boron agent, titanium boron wire according to the alloy composition.

[0029] Melting and casting: Put the prepared raw materials into the regenerative natural gas melting aluminum furnace for smelting, first add metallic pure aluminum and Al-Si intermediate alloy, and then add metallic copper after melting; add manganese agent and chromiu...

Embodiment 1

[0035] a. Prepare materials: according to the scope of the alloy composition of the present invention, with pure metal aluminum, magnesium, copper, Al-Si master alloy, chromium agent, manganese agent, titanium boron agent, titanium boron wire, according to the Si of composition 0.59%, the Fe of 0.13% , 0.22% of Cu, 0.41% of Mn, 0.68% of Mg, 0.18% of Cr, 0.02% of Zn, 0.03% of Ti, 0.6% of Mn+Cr, unavoidable impurity elements each <0.05%, and not Avoid the total amount of impurity elements < 0.15%, and the balance is aluminum alloy.

[0036]b. Melting and casting: Put the prepared raw materials into the regenerative natural gas melting aluminum furnace for smelting, first add metal pure aluminum and Al-Si master alloy, after melting, then add metal copper; heat up to 740℃~750℃ and add manganese agent , chromium agent, and pure magnesium metal. After these metals are stirred evenly and fully melted, the temperature is raised to 750-760°C, and then the molten aluminum is treated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com