A kind of prefabricated bridge pier and its construction method

A prefabricated, bridge pier technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of difficult replacement, poor energy consumption, structural impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

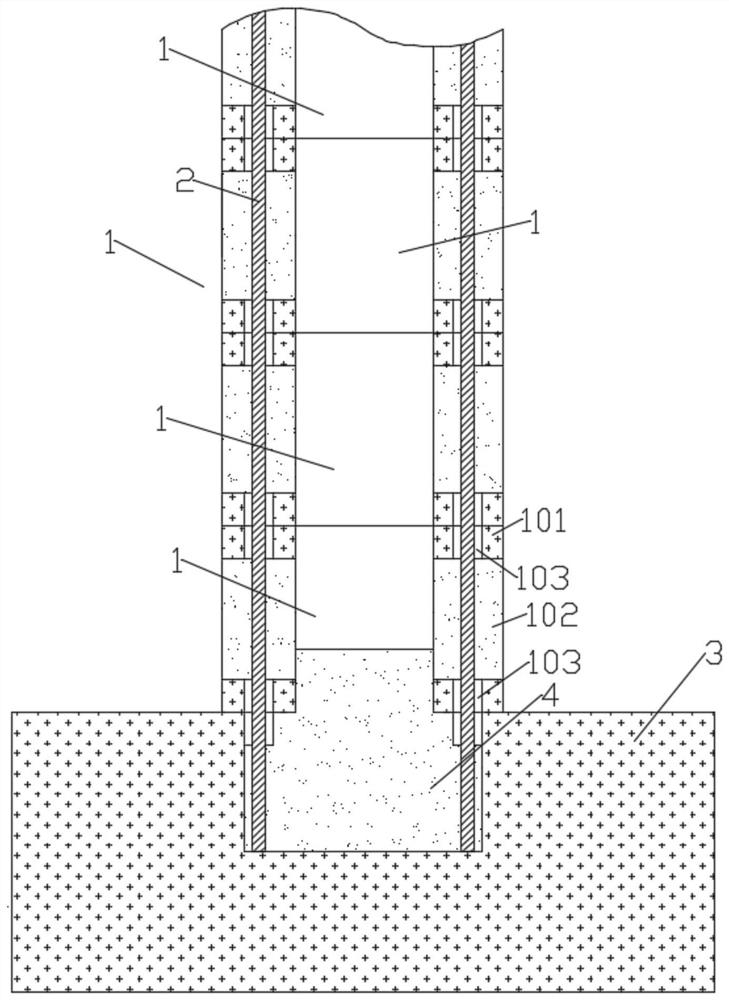

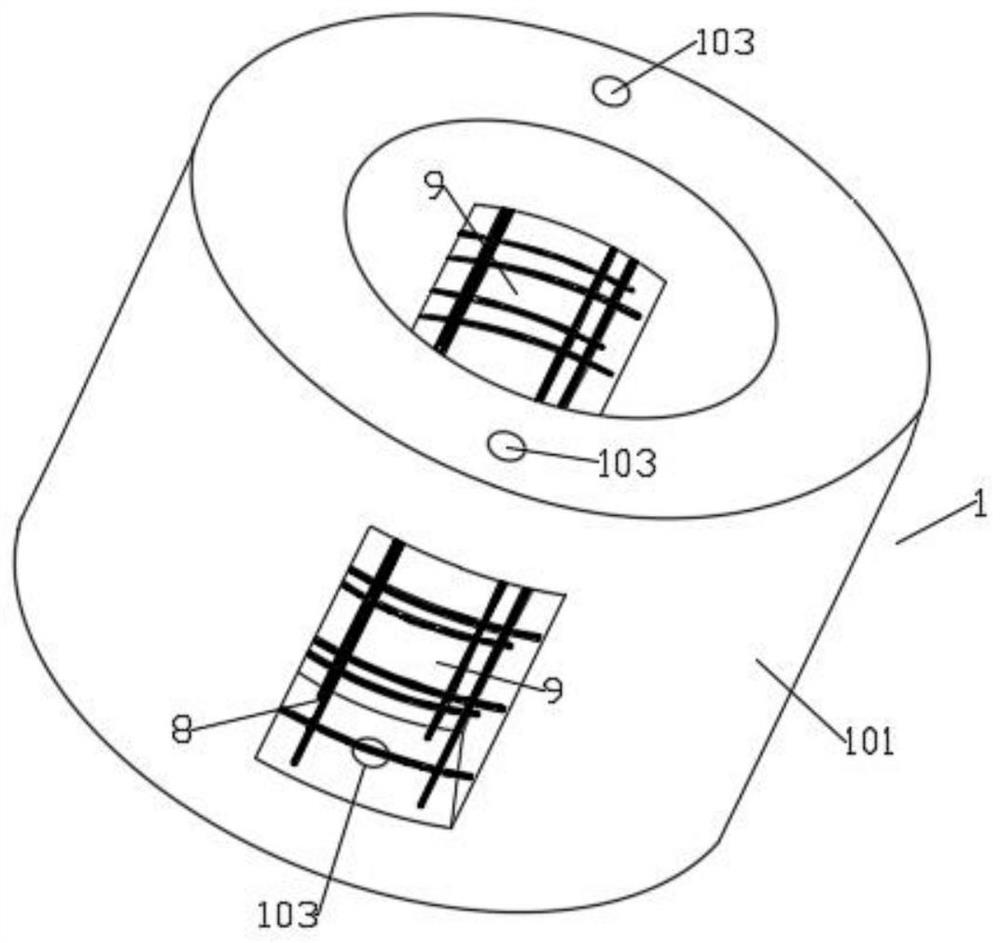

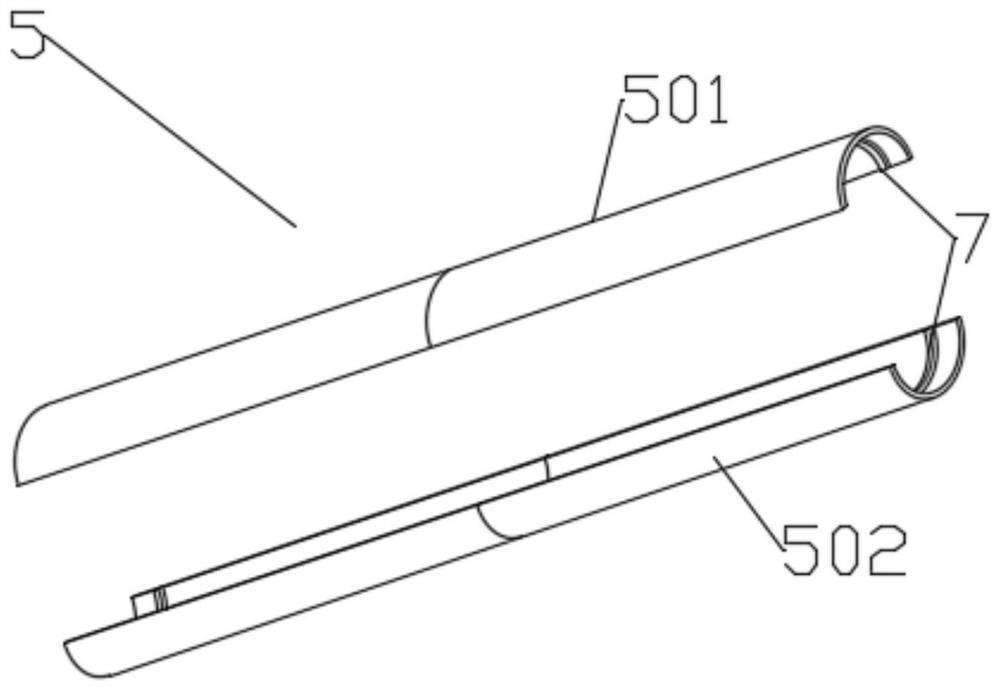

[0021] figure 1 It is the structural representation of the pier of the present invention, figure 2 It is a structural schematic diagram of the segment of the present invention. An assembled bridge pier according to the present invention includes a pier body and energy-dissipating steel bars 2 arranged in the pier body along the axial direction of the pier body. The pier body is formed by assembling several segments 1 sequentially from bottom to top, wherein 4 is the center For pillars, the section 1 includes a section body 101, the side wall of the section body 101 has a hole 9 and forms the cast-in-place part 102 of the section 1 through in-situ casting, and the energy-dissipating steel bar 2 is along the pier body. Axially passing through the several sections 1 sequentially, the energy-dissipating steel bars 2 are respectively gap-conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com