Construction method of lock catch steel tubular pile cofferdam suitable for high water head of estuary

A technology of locking steel pipes and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in ensuring construction period requirements and enterprise benefit requirements, low rigidity, difficulty in ensuring construction safety, and large turnover loss, etc., to achieve Improve turnover utilization, save labor and equipment costs, and ensure continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

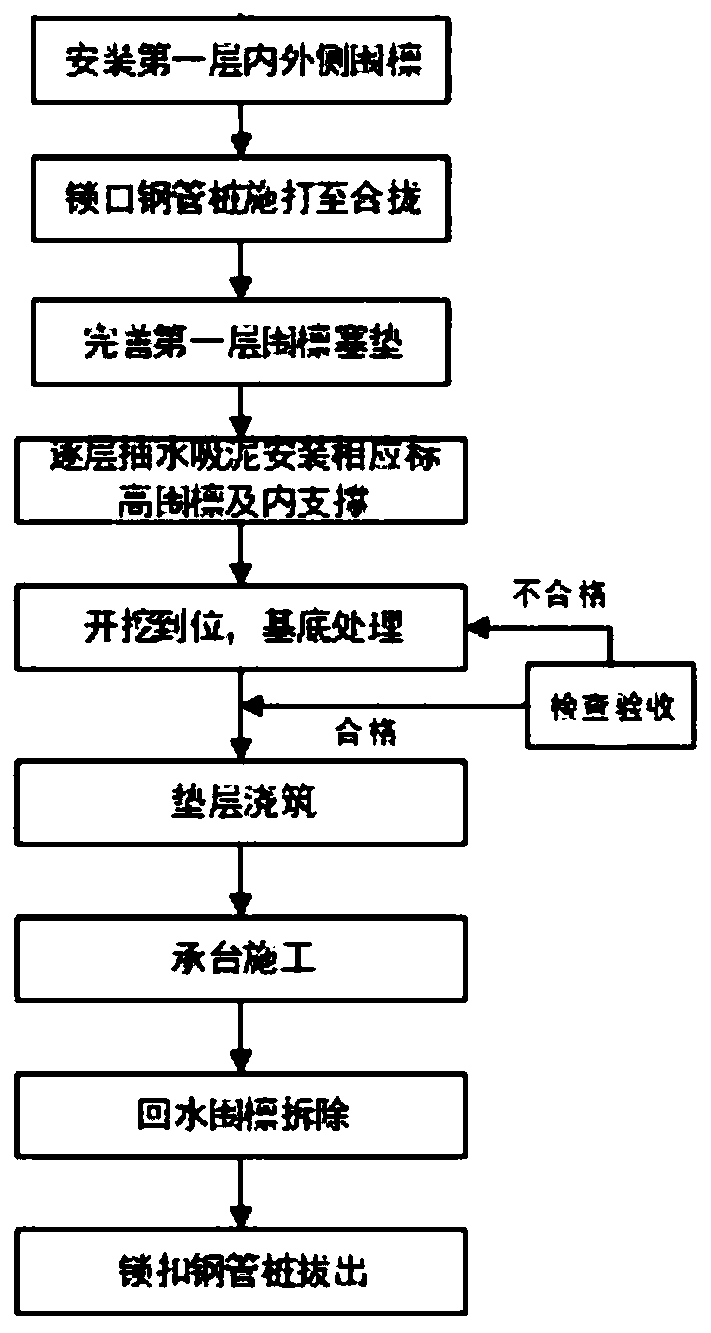

[0035] Such as figure 1 As shown, the present invention provides a kind of construction method of the locking steel pipe pile cofferdam that is applicable to the high water head of estuary, comprises the following steps:

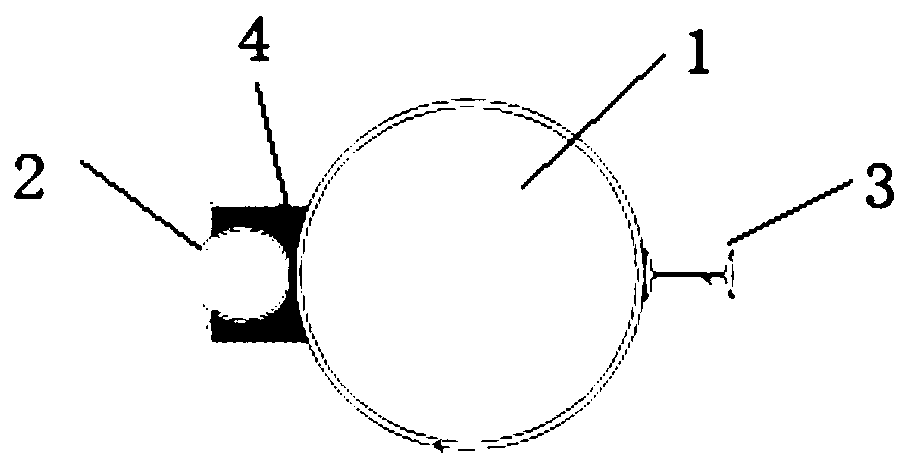

[0036] 1) Install the inner and outer purlins of the first layer section by section, and the distance between the inner and outer purlins is 2-3cm larger than the outer diameter of the locking steel pipe pile; wherein, the locking steel pipe pile includes the middle circular pile 1 and The C-shaped lock 2 and the I-shaped steel lock 3 are symmetrically distributed on both sides, and the two adjacent lock steel pipe piles cooperate with each other through the C-shaped lock and the I-shaped steel lock to realize the buckle connection; the lock A number of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com