Flexibly-connected fabricated wall

A flexible connection and assembly technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve the problems of inability to absorb shocks and match earthquakes, and achieve improved protection and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

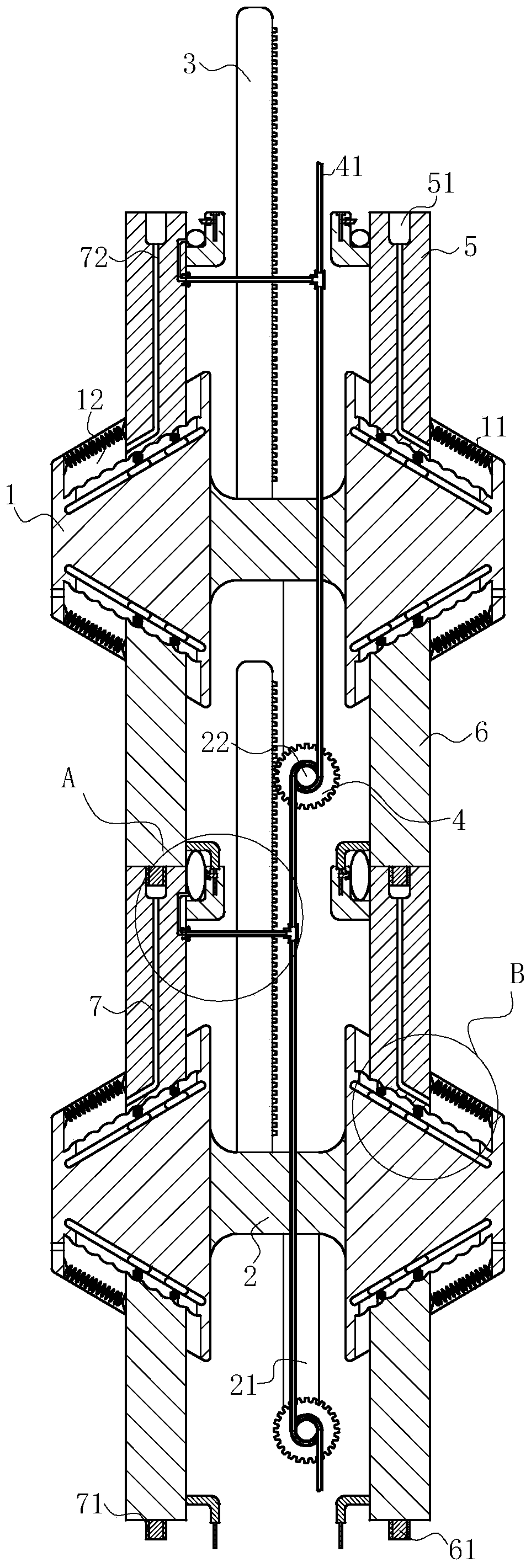

[0019] use Figure 1-Figure 4 A flexible connected prefabricated wall according to an embodiment of the present invention is described as follows.

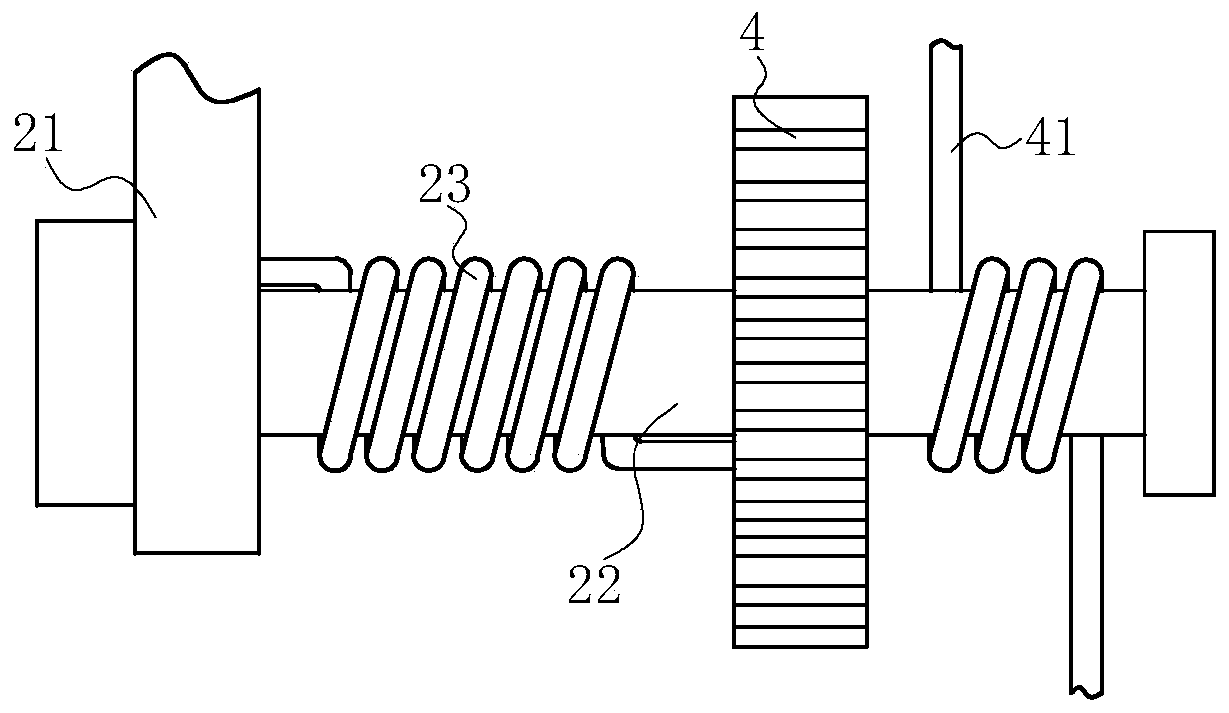

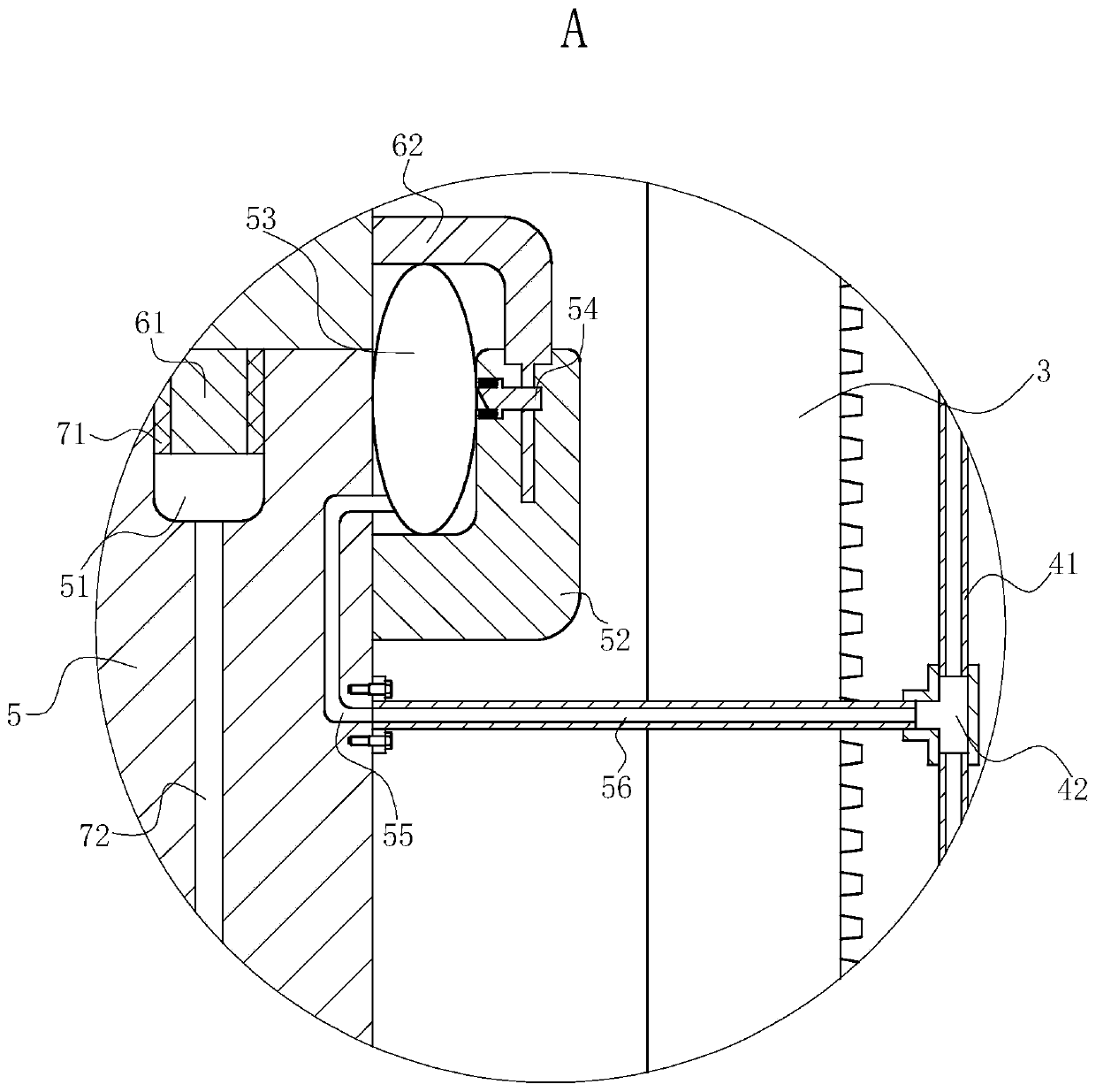

[0020] Such as Figure 1-Figure 4 As shown, a flexible connected assembled wall according to the present invention includes a mounting block 1, a connecting rod 2, a rack 3, a gear 4, a No. 1 connecting plate 5, a No. 2 connecting plate 6 and a stabilizing mechanism 7, The installation block 1 is provided with two pieces, the cross section of the installation block 1 is trapezoidal, and the installation blocks 1 are fixedly connected by the connecting rod 2; The right end of the lower surface is uniformly fixedly connected with a gear 4 through a fixed rod 21 and a rotating shaft 22; the gear 4 can mesh with the rack 3, and a torsion spring 23 is connected between the gear 4 and the fixed rod 21; A No. 1 connecting plate 5 is slidably connected to the wall, and a No. 2 connecting plate 6 is slidably connected to the lower wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com