Double-row piercing terminal connector

A technology of piercing terminals and wire end connectors, which is applied in the direction of connection, conductive connection, and parts of connection devices, etc., can solve problems such as error-prone, waste of manpower and material resources, and electrical accidents in electrical appliances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

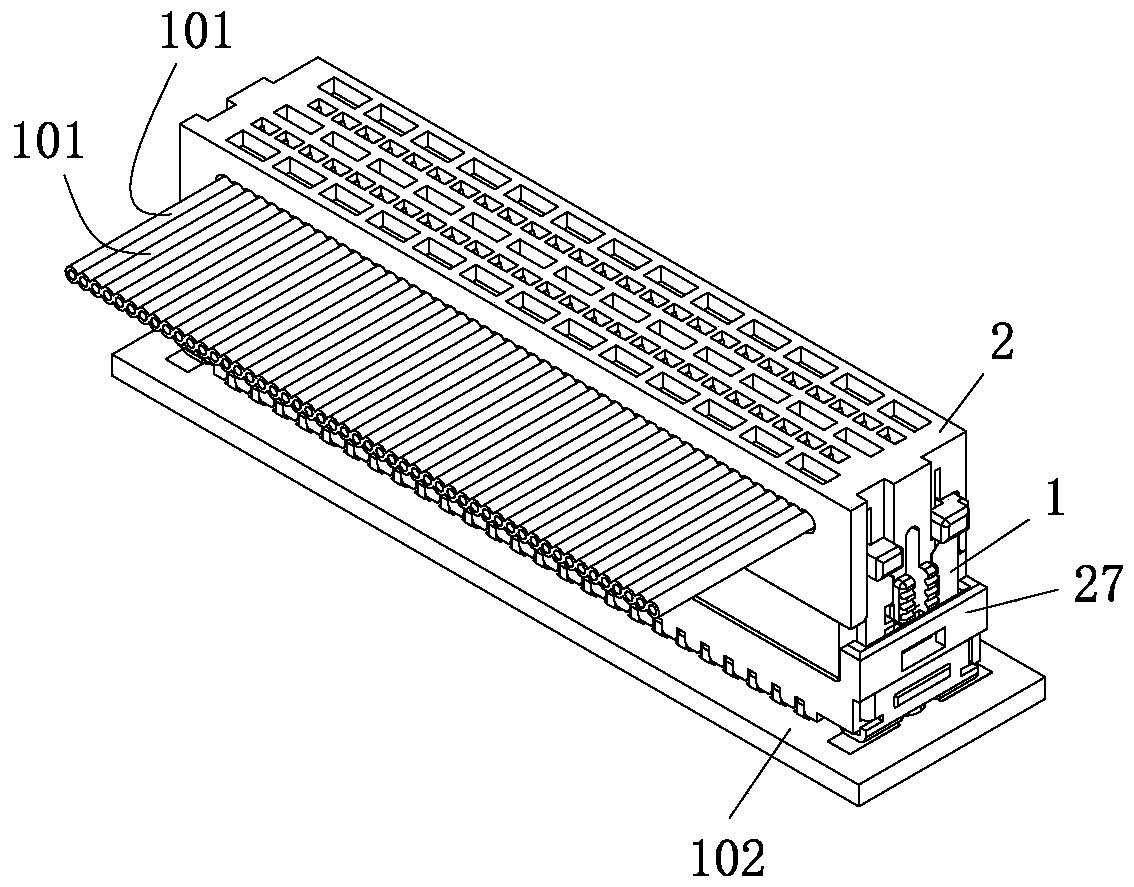

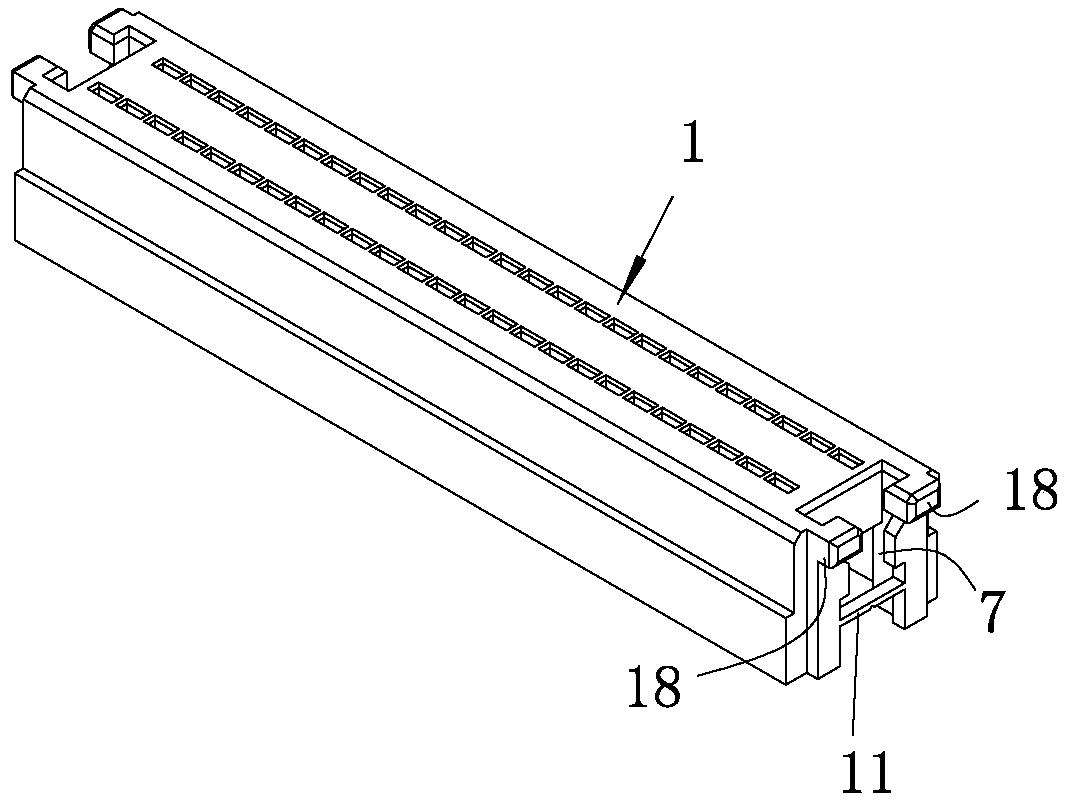

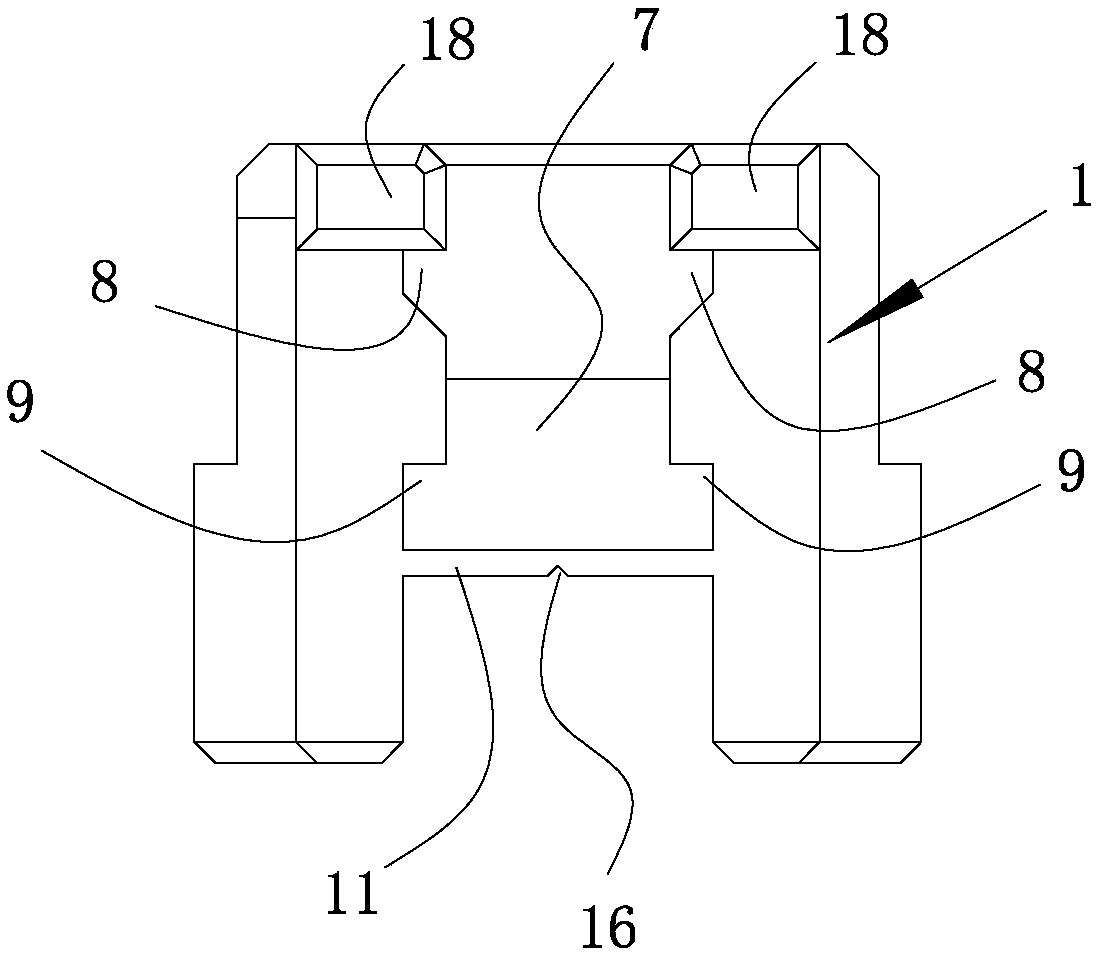

[0041] see Figure 1 to Figure 6 As shown, a double-row piercing type terminal connector of the present invention includes a line end connector, and the line segment connector has a line end rubber shell 1, a cover 2 that is plugged and matched with the line end rubber shell 1, and is provided with a line end rubber shell The male terminal 3 on 1, the wire end rubber case 1 and the cover 2 are all made of insulating plastics. Preferably, the wire end rubber case 1 and the cover 2 are injection molded through injection molds respectively.

[0042] There is a piercing part 4 on the male terminal 3, and the piercing part 4 is located at the upper end of the male terminal 3. The cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com