Electric shock preventing connector and electric shock preventing connector with signal transmission function

An anti-electric shock and connector technology, applied in the parts, connections, circuits and other directions of the connecting device, can solve the problems of black burning, human electric shock accidents, and family scars of the parties concerned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

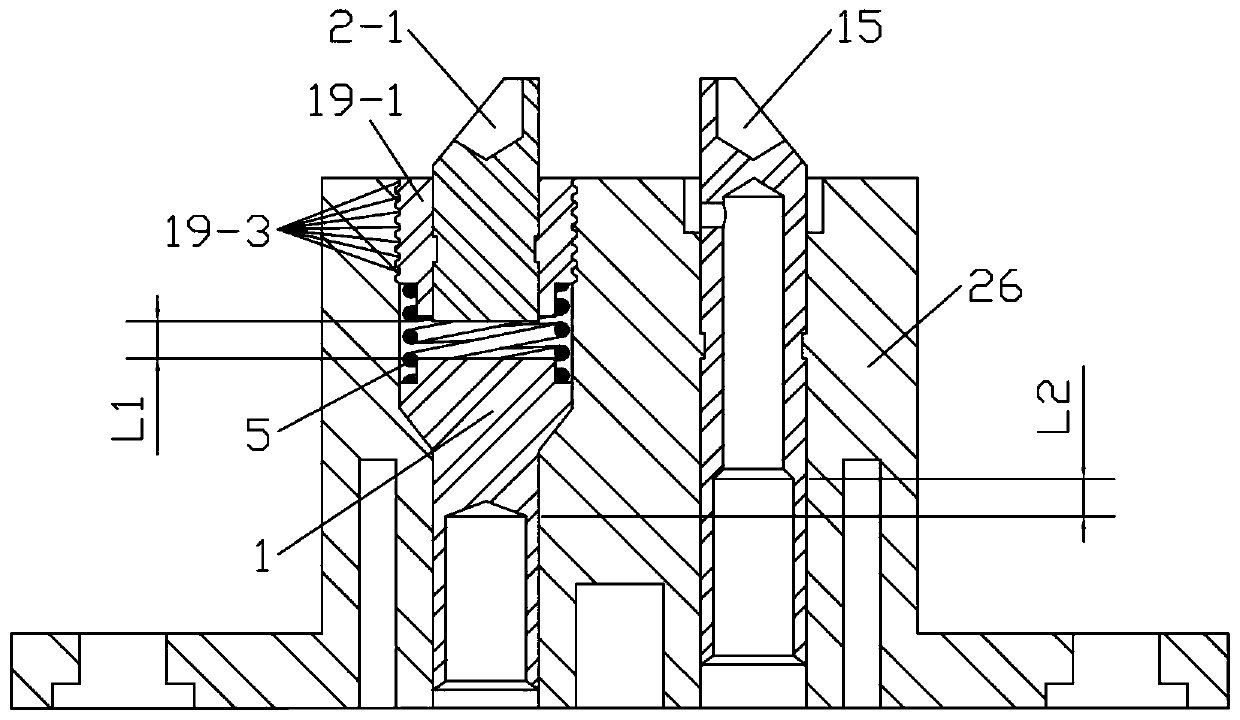

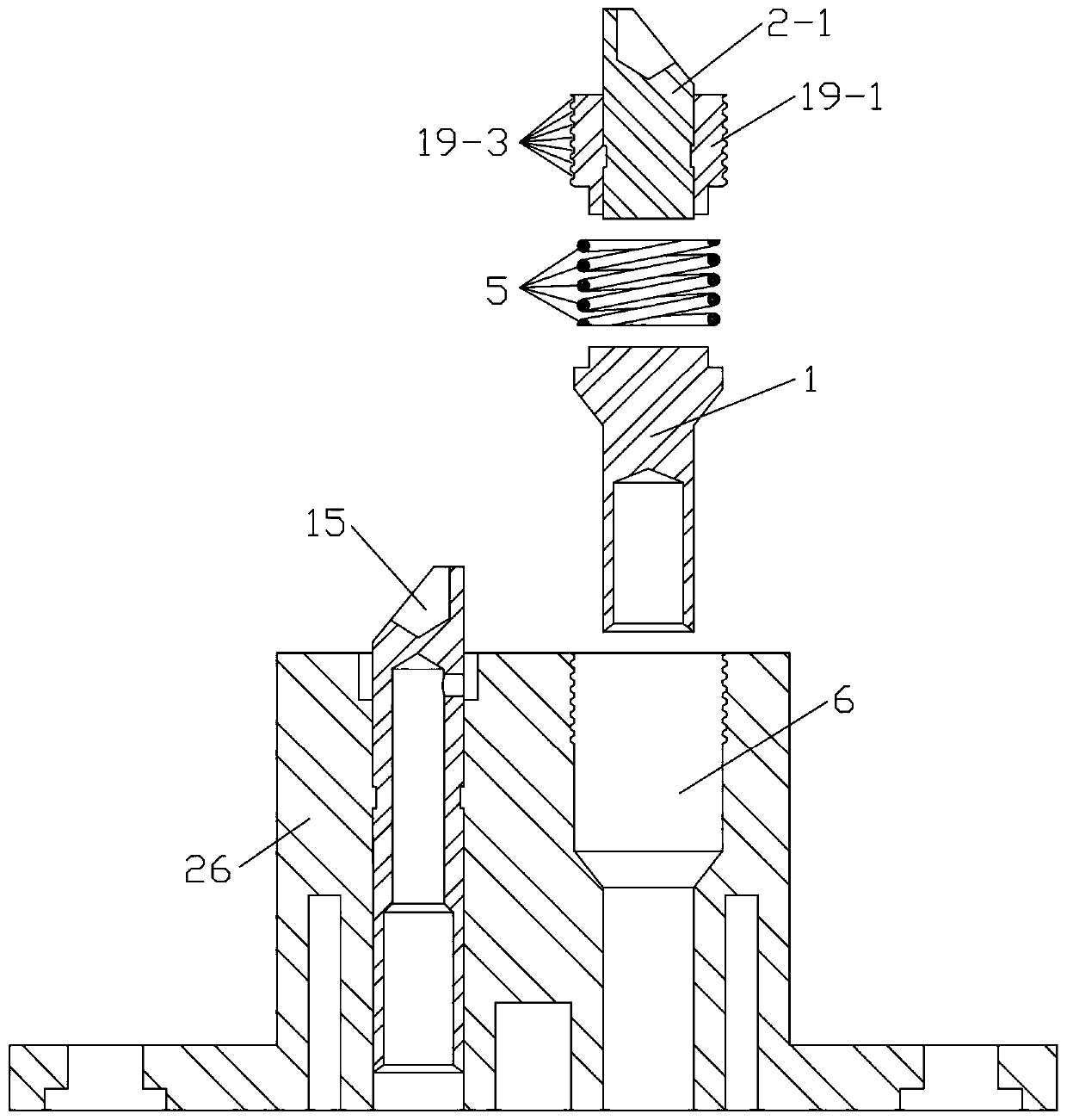

[0055] Such as figure 1 , figure 2 As shown, the anti-shock connector female head 26 is composed of a common female electrode 15, an insulating body, an electric-shock-proof front-end female electrode 1, a spring 5, and an electric-shock-proof rear-end female plug 19-1 with a welding wire gap; The anti-shock rear-end female plug 19-1 is composed of an electric-shock-proof rear-end female electrode 2-1 with a welding wire gap and an insulating shell; the common female electrode 15 is integrally injection-molded in the insulating main body, and the insulating main body has an insulating positioning groove 6. The insulation positioning groove 6 is located on the other side of the ordinary female electrode 15; the electric shock-proof front-end female electrode 1 is placed on the front end of the insulation positioning groove 6, and the spring 5 is placed on the electric shock-proof front-end female electrode 1 and the anti-shock electrode with a welding wire gap. Between the el...

Embodiment 2

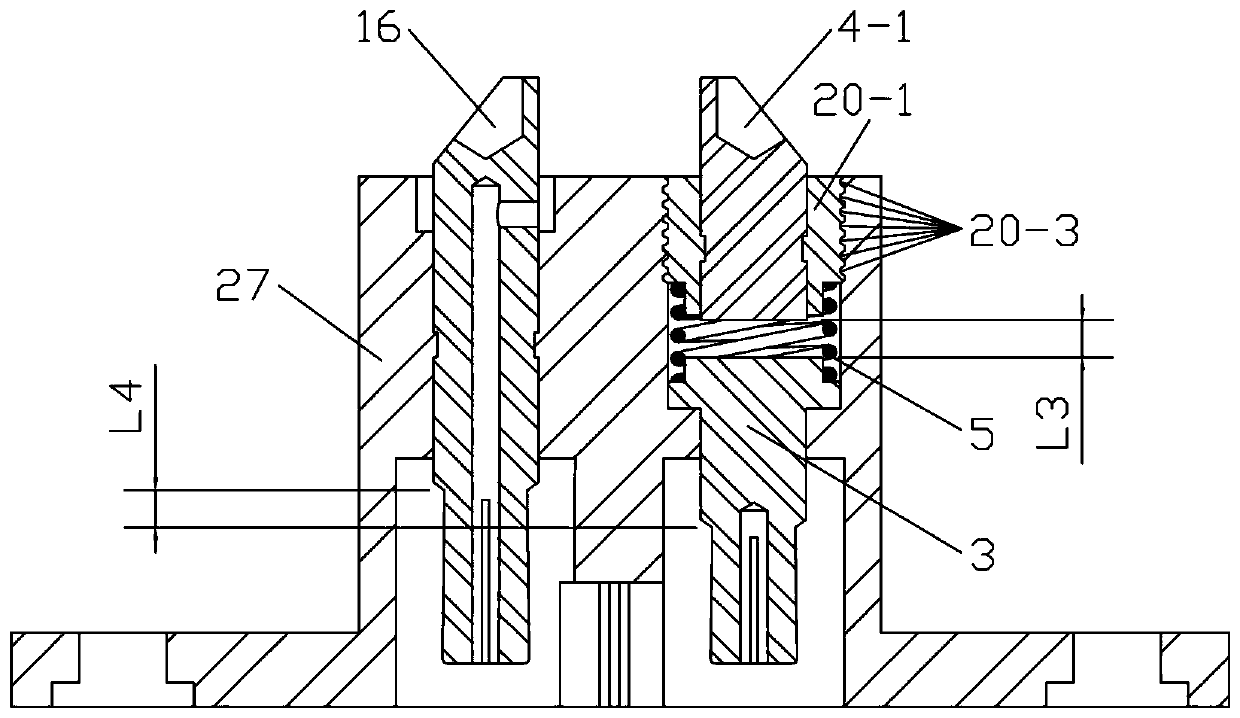

[0058] Such as Figure 7 As shown, the anti-shock anti-short-circuit connector female head 28 is composed of an anti-short-circuit female electrode 7, an insulating body, an electric-shock-proof front-end female electrode 1, a spring 5, and an electric-shock-proof rear-end female plug 19-1 with a welding wire gap; anti-short circuit The female electrode 7 is composed of a first female electrode 13-1, a fuse 21, a plastic protective case, and a second female electrode 13-3 with a welding wire gap; The anti-shock rear end female electrode 2-1 of the line gap is composed of an insulating shell; the anti-short circuit female electrode 7 is integrally injection-molded in the insulating main body, and the insulating positioning groove 6 is arranged in the insulating main body, and the insulating positioning groove 6 is located in the anti-short circuit female electrode The other side of the anti-shock front-end female electrode 1 is placed in the front end of the insulating position...

Embodiment 3

[0060] Such as Figure 9 As shown, the anti-shock anti-short-circuit connector female head 28 is composed of a first female electrode 13-1, a fuse 21, an anti-short-circuit rear-end female plug 22-1 with a welding wire gap, an insulating body, an electric-shock-proof front-end female electrode 1, and a spring 5. The anti-shock rear female plug 19-1 with a welding wire gap; the anti-short circuit rear female plug 22-1 with a welding wire gap is composed of a second female electrode 13-3 with a welding wire gap and a plastic shell; The electric-shock-proof rear-end female plug 19-1 with a welding wire gap is composed of an electric-shock-proof rear-end female electrode 2-1 with a welding wire gap and an insulating shell; the first female electrode 13-1 is integrally injection-molded in the insulating body , the rear end of the insulating body has an insulating column groove connected to the rear end inner hole of the first female electrode 13-1; after the fuse 21 is placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com