Position-adjustable inner plate positioning mechanism for stamping parts in cold-punching and edge-coating processes

A positioning mechanism and cold stamping technology, applied in the field of mechanical equipment, can solve problems such as scraping workpieces, difficulty in adjusting the position of positioning pins for debuggers, misalignment of inner plates, etc., to ensure relative position accuracy, solve difficulty in picking parts, and reduce debugging. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

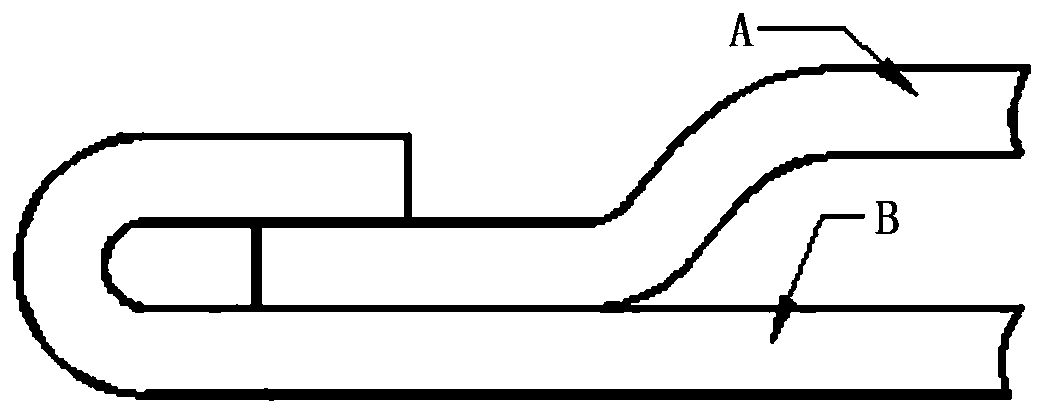

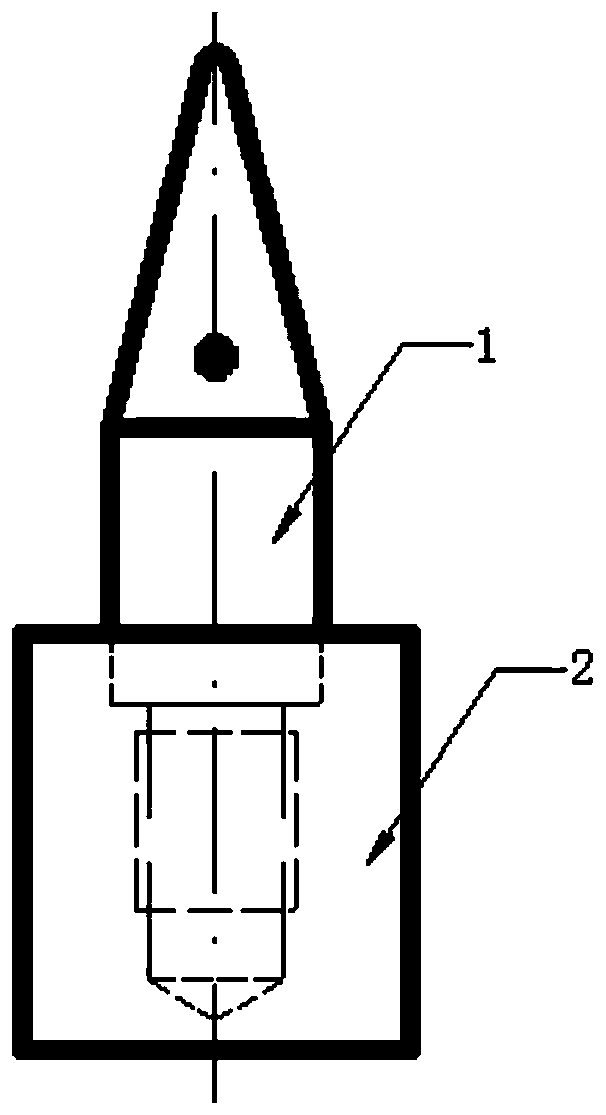

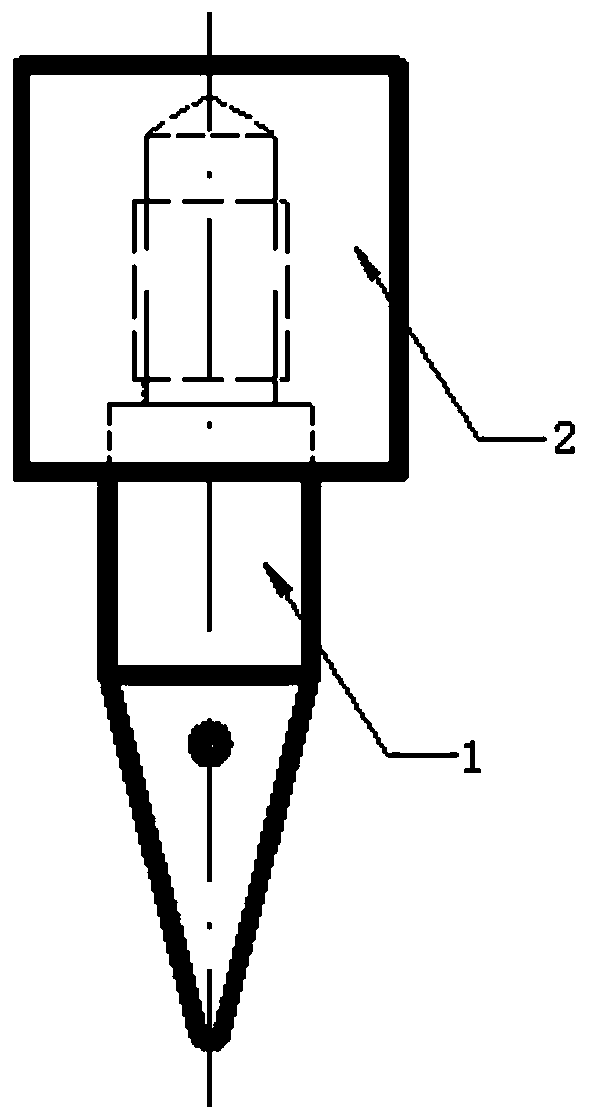

[0015] refer to Figure 7 , The positioning mechanism of the present invention includes a flat L-shaped adjustment seat 5 installed at the lower end of the upper mold. The vertical Z-shaped positioning pin frame 3 that can adjust the position relatively to the adjusting seat in a small amount, the adjusting gasket 4 between the adjusting block 5 and the positioning pin seat 3, the tightening screw between the adjusting block 5 and the positioning pin seat 3, and the positioning The flat part of the Z-shaped upper end of the pin seat 3 is located in the inner corner of the L-shaped adjustment block 5. There are fixing screw holes and positioning pin holes on the adjustment block 5. The pin is positioned at the lower end of the upper die. There are two mutually perpendicular flat screw holes on the adjustment block 5. The flat part of the Z-shaped upper end of the positioning pin seat 3 has a threaded hole opposite to the flat screw hole of the adjustment block 4. The tightenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com