Feeding and taking device for warehouse transportation

A material retrieving device and material storage technology, which is applied in the field of sheet metal parts transportation, can solve the problems of unsatisfactory adsorption effect, inconvenient control and use, single suction cup method, etc., and achieve the effect of easy promotion and use, convenient transportation and use, and stable adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

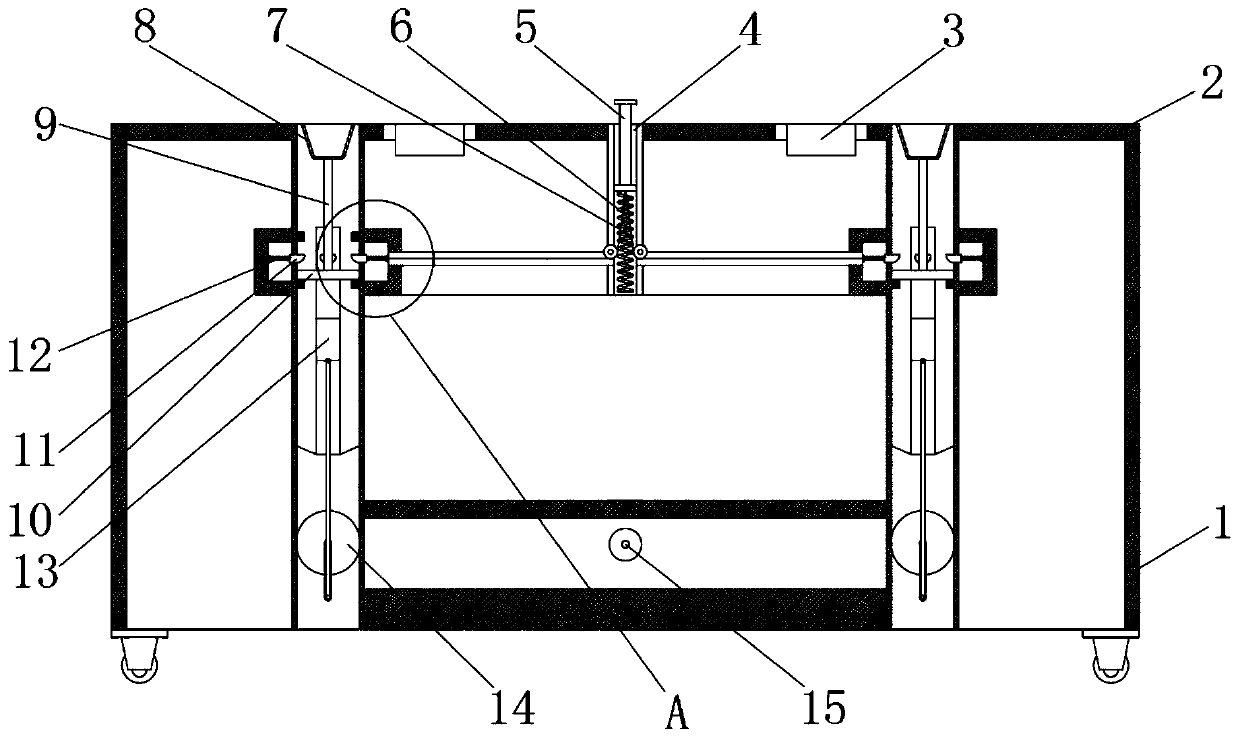

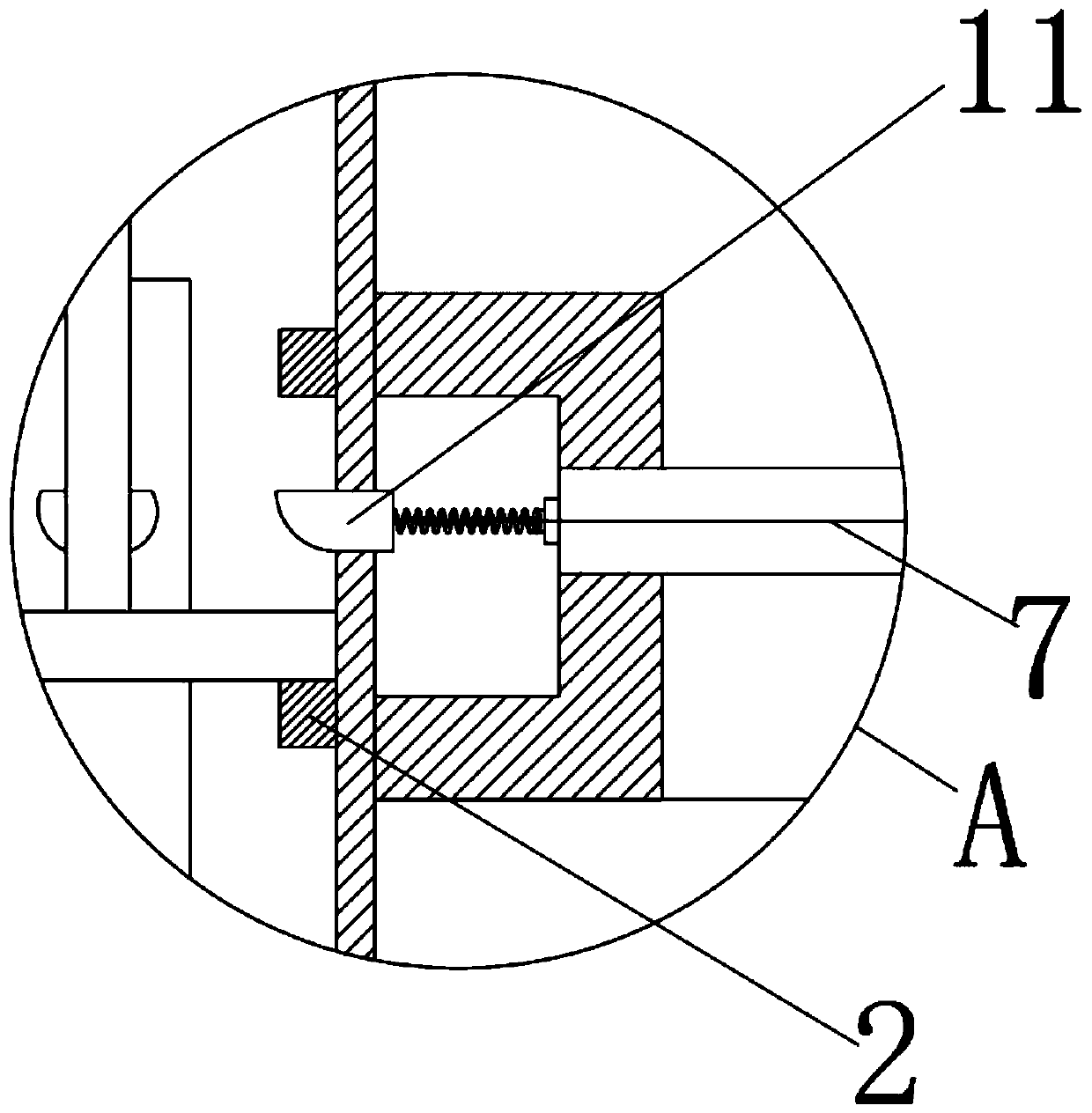

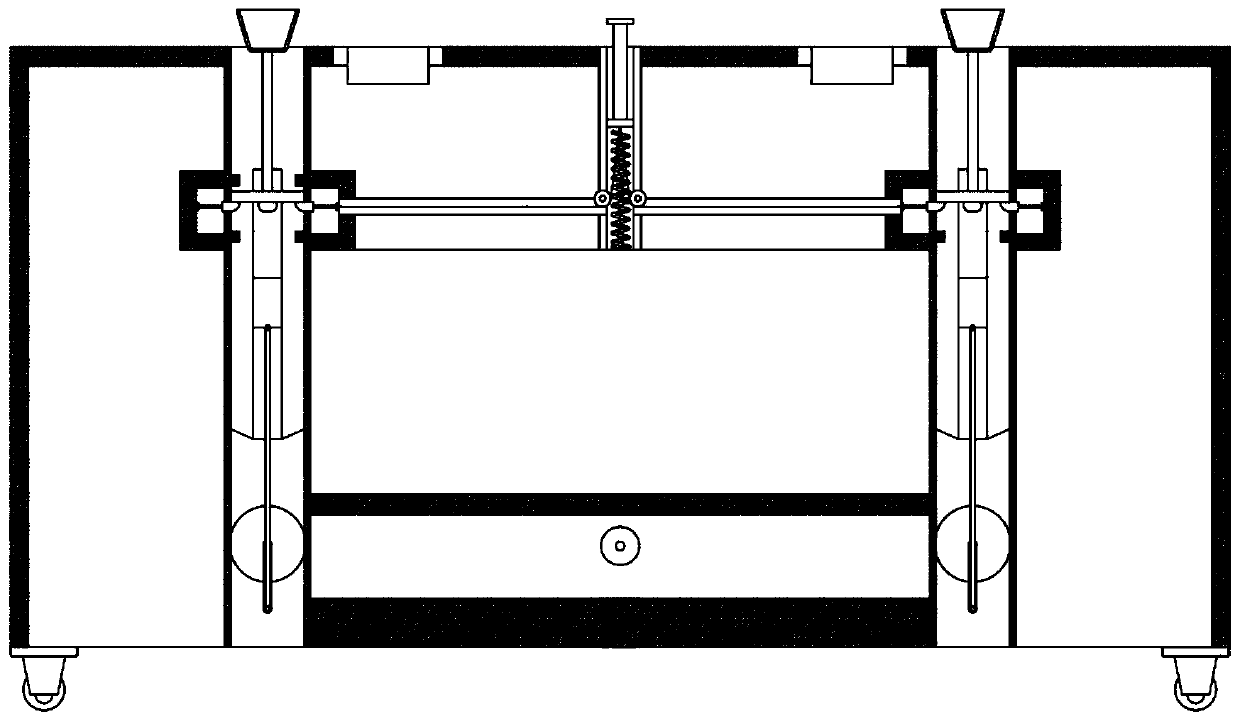

[0020] Such as figure 1 , figure 2 As shown, a feeding and retrieving device for warehouse transportation includes a feeding trolley body 1 carrying sheet metal materials on the upper end surface, and an auxiliary hole is opened on the upper end surface of the feeding trolley body 1, and a fixed mechanism, the lower end of the fixing mechanism is provided with an ejection mechanism, and the inner wall surface of the auxiliary hole is provided with a limit mechanism. The sheet metal material on the upper surface of the feeding trolley body 1 is fixed.

[0021] The upper outer surface of the feeding trolley body 1 is provided with a trigger mechanism, and the trigger mechanism returns the fixing mechanism to the original position after the sheet metal part leaves the upper outer surface of the feeding trolley body 1;

[0022] The fixing mechanism includes a fixed disk 8. In this embodiment, the fixed disk 8 is a suction cup, and its body itself is an elastic rubber part. The ...

Embodiment 2

[0025] On the basis of the above-mentioned embodiments, the fixed plate 8 can be replaced by a vacuum suction cup, and its support rod 10 is a hollow structure. One side of the support plate 10 is provided with an air inlet and outlet pipe, an external air pump and a corresponding air valve, in the unlocking hole 4 or An inductive switch is arranged at the bottom of the unlocking lever 10 , and the inductive switch is triggered by the friction or pressure of the unlocking lever 5 , thereby starting the operation of the driving mechanism 15 .

[0026] When in use, it should also be noted that firstly use the air valve or air pump to process the intake air, balance the air pressure in the fixed plate 8, thereby unlocking the fixing of the sheet metal part, and then move the sheet metal part, because the unlocking lever 5 is in the position of the sheet metal part It has a recovery characteristic after being moved, and the solid induction switch should be a switch that can be star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com