Automatic collecting device for stamping machine waste base films

A technology of automatic collection and hot stamping machine, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., to achieve the effect of convenient collection of waste base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

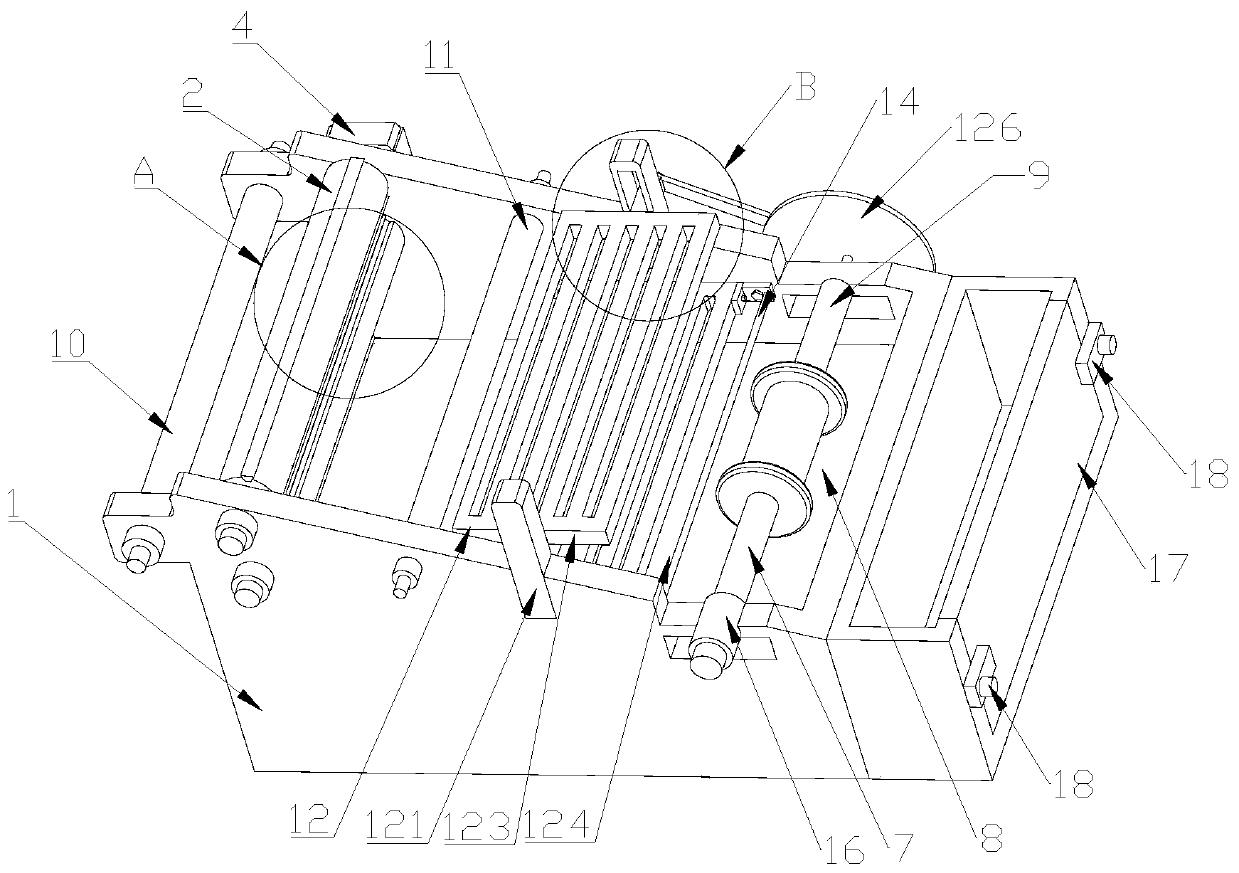

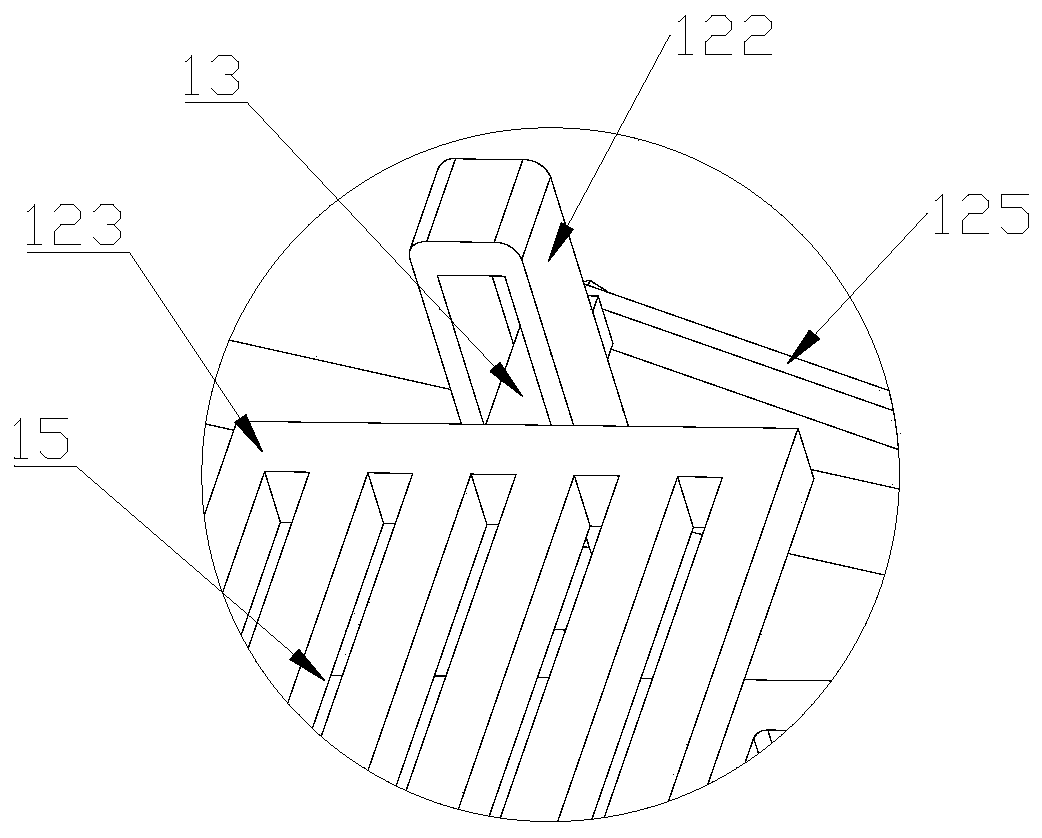

[0029] like Figure 1 to Figure 5 , an automatic collection device for the waste base film of a bronzing machine, which is installed at the output end of the waste base film layer, and includes a workbench 1, and the upper surface of the workbench 1 is inclined from left to right;

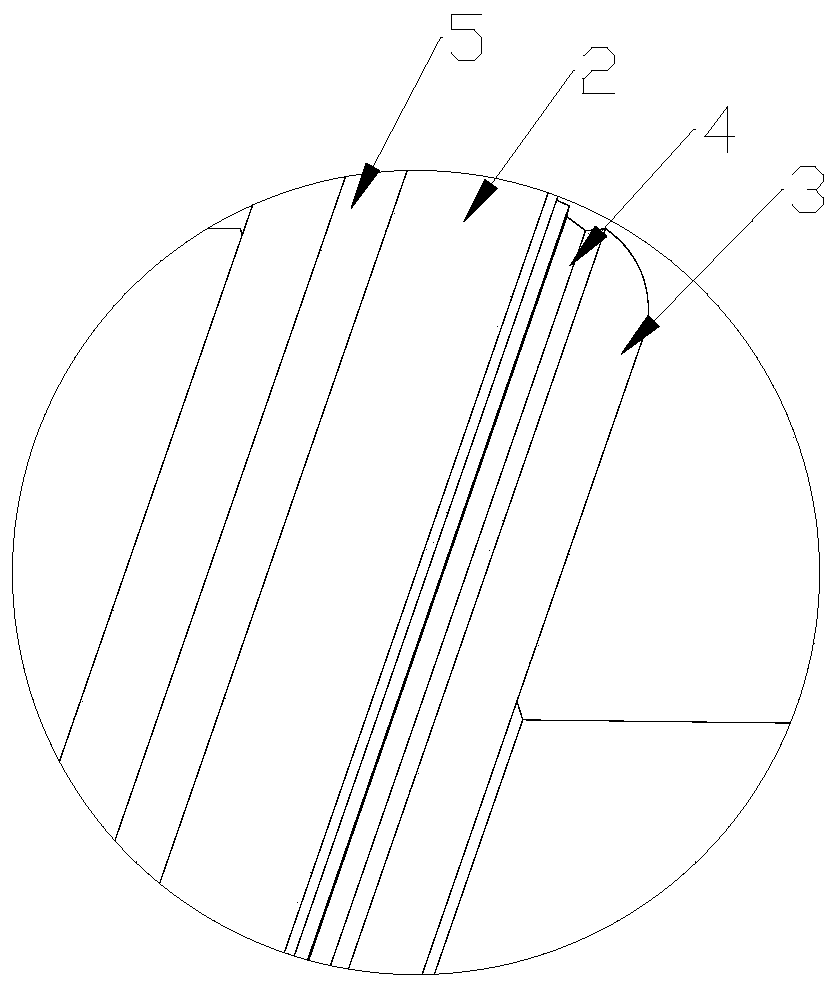

[0030] The high end of the table 1 is the input end, and the input end is provided with a driving roller 2 and a driven roller 3. The driving roller 2 and the driven roller 3 are arranged side by side up and down. The first channel through which the film passes, the driving roller 2 is driven by the motor 4 set on the worktable 1, and the driven roller 3 is driven by the belt to rotate opposite to the driving roller 2 (the driving roller 2 rotates counterclockwise, and the driven roller 3 rotates clockwise. ), a plurality of protrusions 5 are arrayed on the outer circumferential surface of the driving roller 2, the protrusions 5 are arranged along the axis direction of the driving roller 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com