Aluminum alloy semi-rigid beam and column joint connected through ring groove rivets

A technology of ring-groove rivets and beam-column joints, applied in the direction of rivets, rod connections, connecting components, etc., can solve the problems of small initial rotational stiffness and insufficient bearing capacity of aluminum alloy connection joints, so as to overcome the problem of strength reduction and improve Mechanical properties, the effect of accelerating construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through the description of the drawings and specific implementation examples.

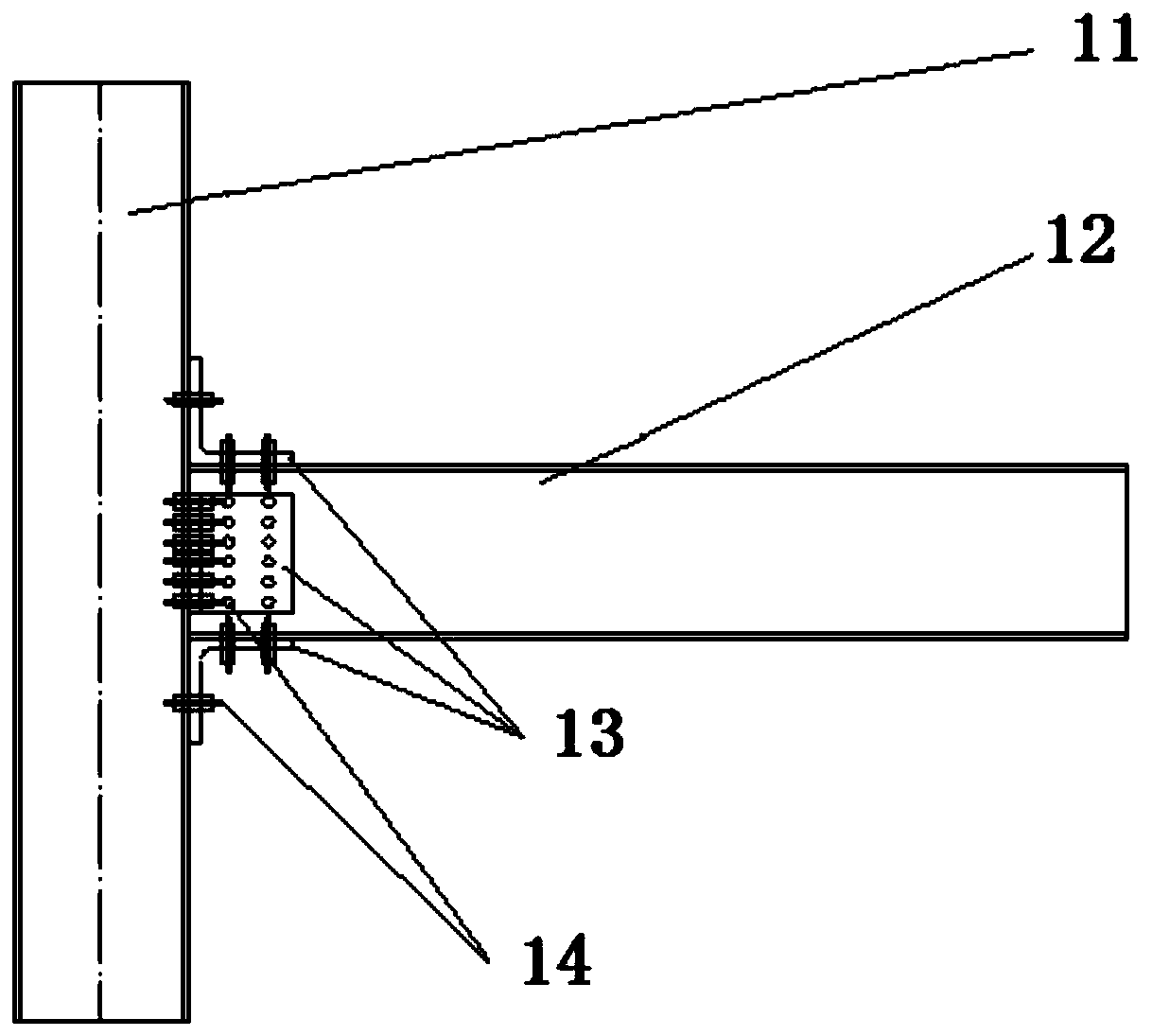

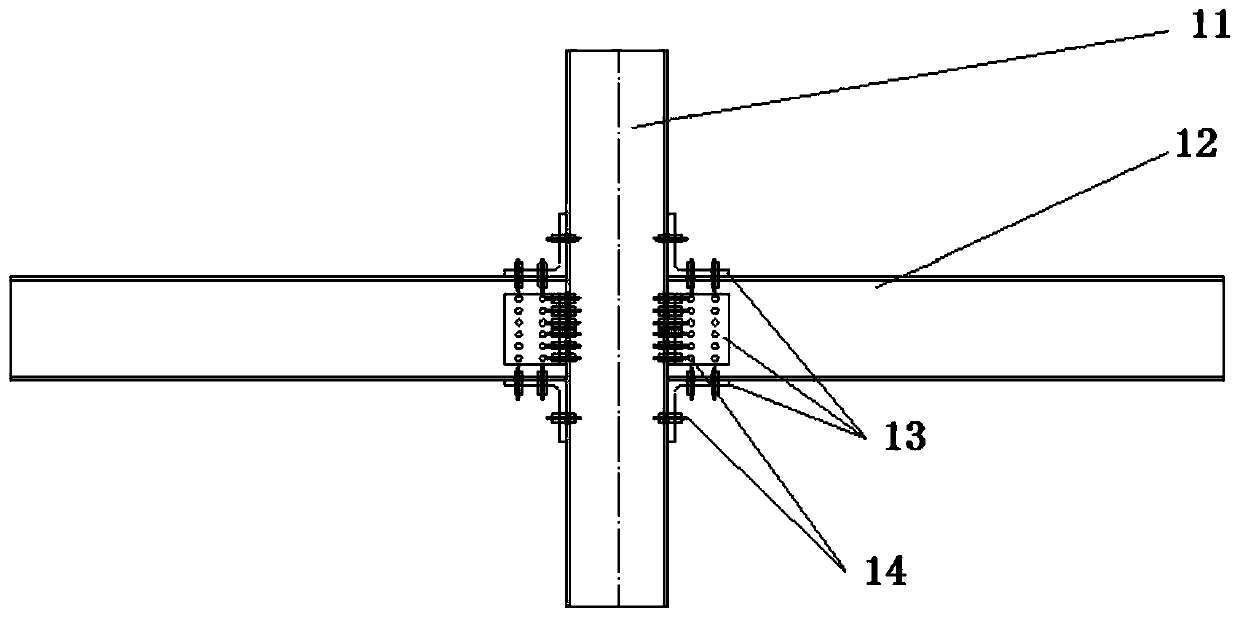

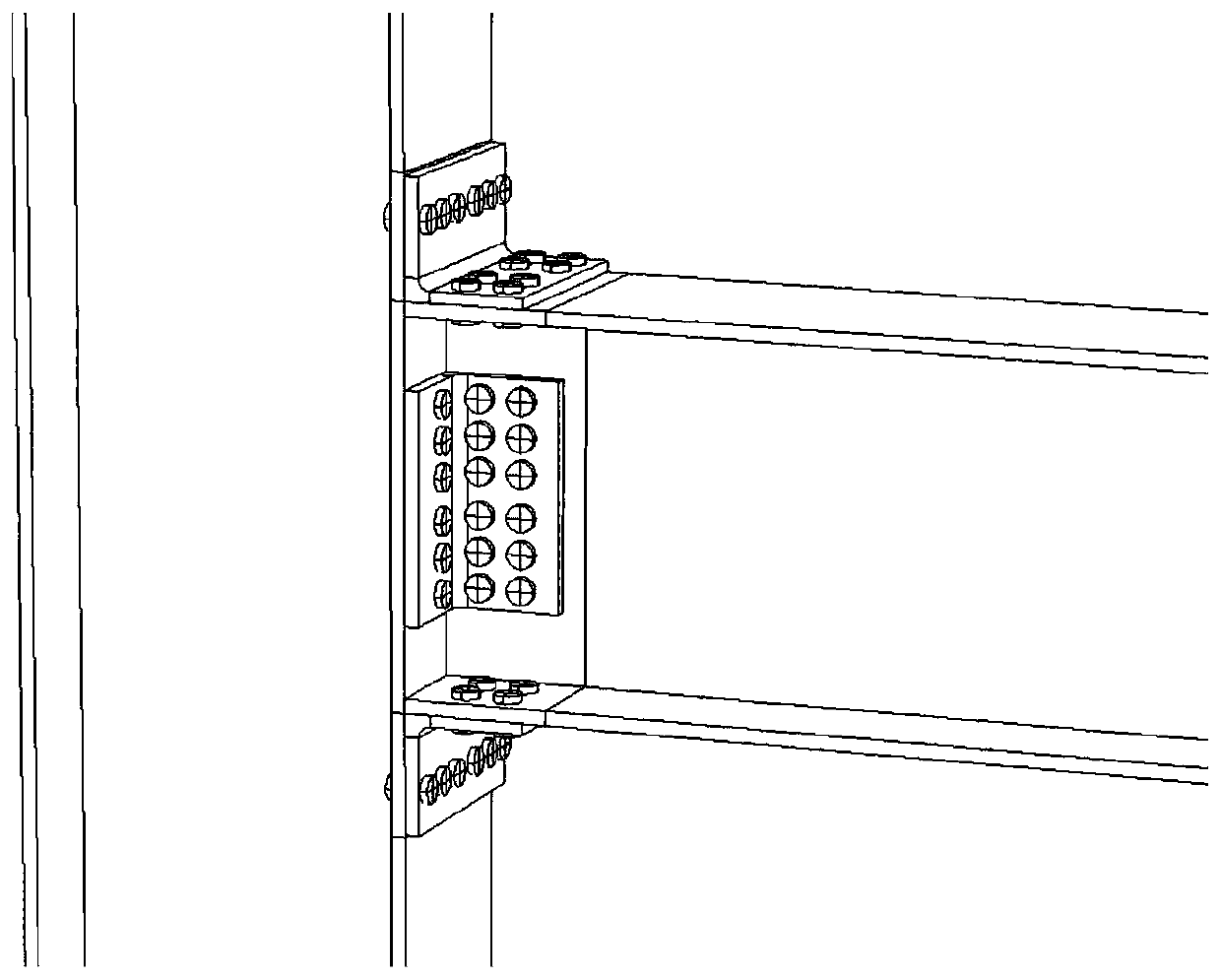

[0032] In order to realize the effective connection of aluminum alloy beams and columns in the frame structure, the present invention proposes a novel aluminum alloy semi-rigid beam-column joint connected by ring groove rivets as fasteners. The node can be quickly assembled at the construction site, has high strength and initial rotational stiffness, and overcomes the strength reduction problem of the welded node and the electrochemical corrosion problem of the bolted node. As a new type of connecting fastener, the ring groove rivet can provide high pre-tightening force, and is anti-loosening and anti-vibration. This new type of node can greatly improve the mechanical properties of the aluminum alloy structure and accelerate the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com