Device and method for rapid pouring of building walls

A kind of building wall, fast technology, applied in construction, building components, building structure and other directions, can solve the problems of high labor intensity, difference in pouring time and slurry amount, affecting the quality of building walls, etc. Less, high applicability, uniform effect of pouring construction slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

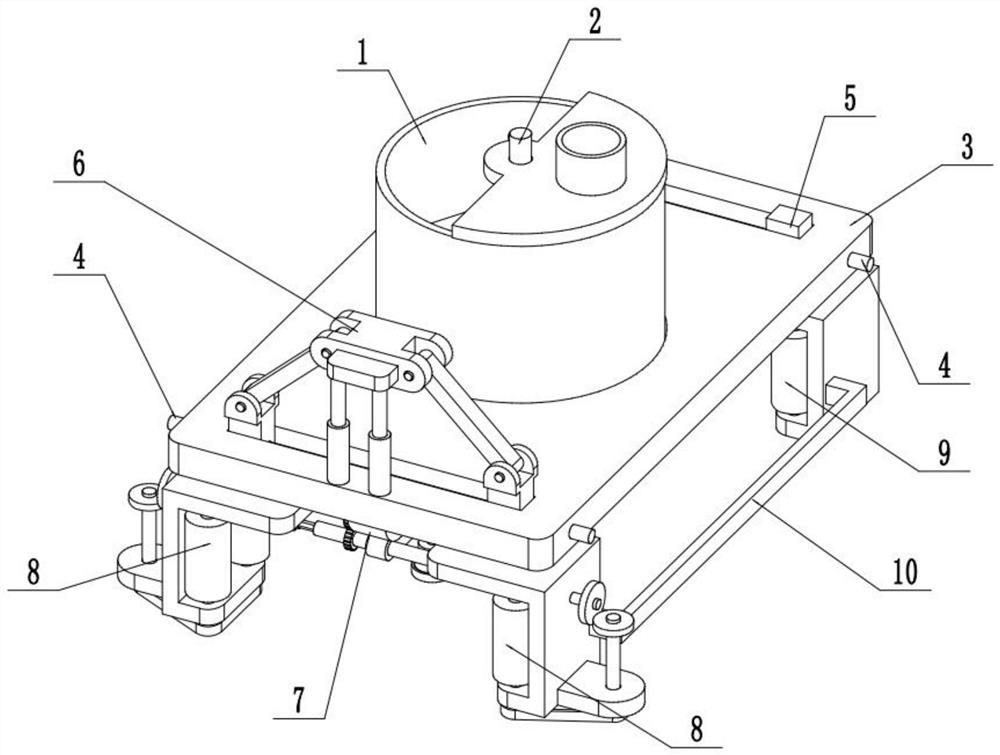

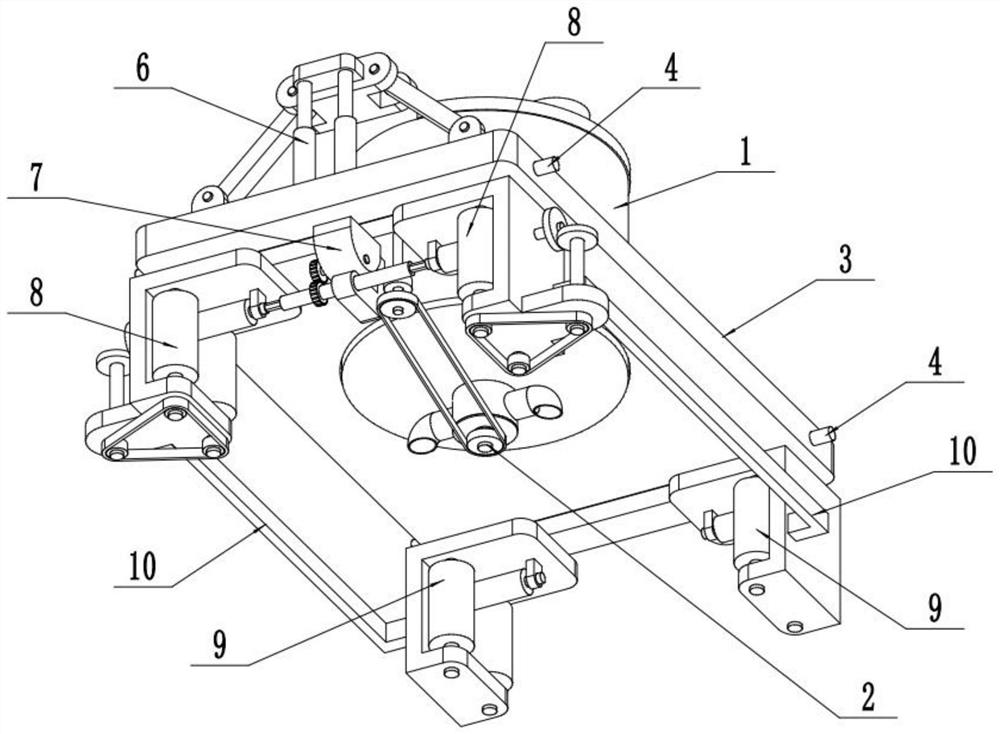

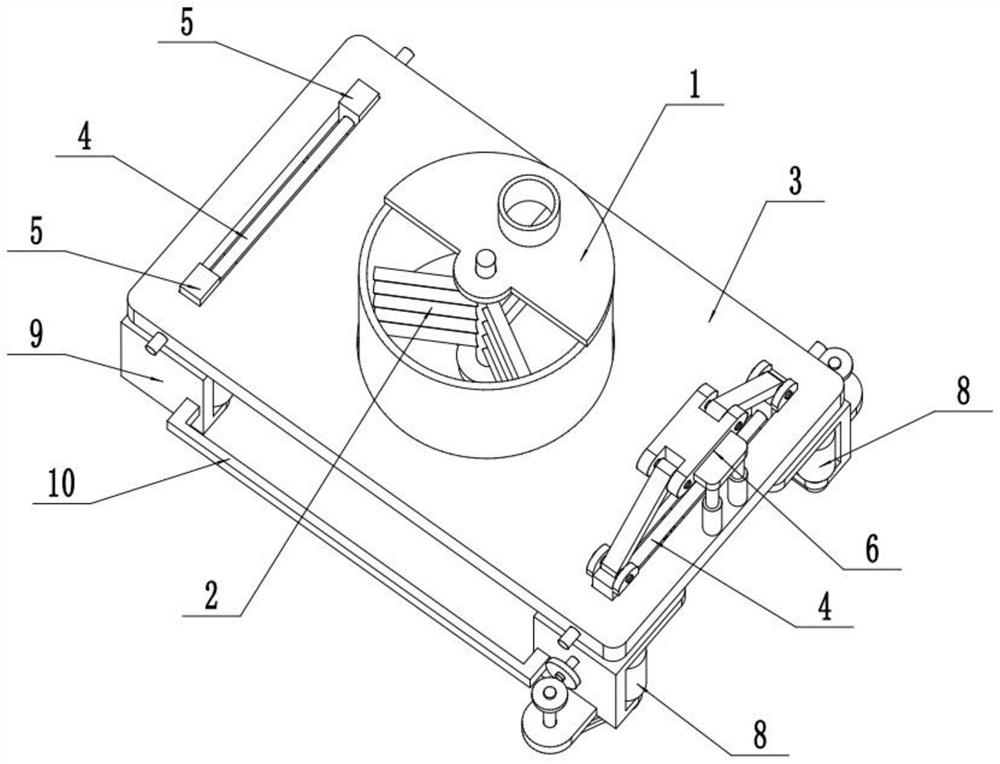

[0036] like Figure 1-13 As shown, a rapid pouring device for building walls includes a pouring cylinder 1, a stirring and conveying mechanism 2, a horizontal frame 3, a guide shaft 4, a guide slider 5, a distance adjustment mechanism 6, a drive control mechanism 7, and an active walking mechanism 8. The passive walking mechanism 9 and the first linkage frame 10, the pouring cylinder 1 is fixedly connected in the circular through hole in the center of the horizontal frame 3; The top surface and the bottom surface of the cylinder 1; the horizontal frame 3 is provided with two front and rear rectangular chutes, and the inner sides of the two rectangular chutes are respectively fixedly connected with a guide shaft 4; one end of the distance adjustment mechanism 6 is slidably fitted Connected to a guide shaft 4, the distance adjustment mechanism 6 is slidably connected to a rectangular chute, and the other end of the distance adjustment mechanism 6 is fixedly connected to the hori...

specific Embodiment approach 2

[0038] like Figure 1-13 As shown, the casting cylinder 1 includes a feed pipe 1-1, a cylinder cover 1-2, a cylinder body 1-3, a material control pipe 1-4 and a pouring pipe 1-5; the feed pipe 1-1 is fixed Connected in the feeding port of the cylinder cover 1-2, the cylinder cover 1-2, the cylinder body 1-3 and the material control pipe 1-4 are fixedly connected from top to bottom; the two sides of the material control pipe 1-4 They are respectively fixedly connected and communicated with a pouring pipe 1-5. The inside of the pouring cylinder 1 is used to inject the slurry used for pouring the building wall, and the feed pipe 1-1 at the upper end of the pouring cylinder 1 passes through the telescopic hose with the slurry pump and the slurry stored with the slurry. The tank is connected, and the slurry to be poured is injected into the pouring cylinder 1 through the telescopic hose with the slurry pump; the slurry can enter the two pouring pipes through the cooperation of the...

specific Embodiment approach 3

[0040] like Figure 1-13 As shown, the stirring and conveying mechanism 2 includes a rotating shaft 2-1, a stirring roller 2-2, a feeding screw 2-3 and a driven sprocket 2-4; the top and bottom ends of the rotating shaft 2-1 are respectively Rotationally connected to the bottom surface of the cylinder cover 1-2 and the material control pipe 1-4; the upper end of the rotating shaft 2-1 is uniformly surrounded and fixedly connected to a plurality of stirring rollers 2-2, and the plurality of stirring rollers 2-2 are rotatably connected to the Inside the cylinder 1-3; the lower end of the rotating shaft 2-1 is fixedly connected to the feeding screw 2-3, and the feeding screw 2-3 is rotatably connected to the material control pipe 1-4; the rotating shaft 2-1 The lower end is fixedly connected with the driven sprocket 2-4, and the driven sprocket 2-4 is located at the lower end of the material control pipe 1-4. When in use, the stirring and conveying mechanism 2 is used to stir th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com