Method for preventing perforating injury of optical cable of tubular column in horizontal well

A technology for horizontal wells and pipe strings, applied in the field of perforating oil and gas wells, can solve the problems of irregular twisting of casing, inability to accurately avoid optical fibers, and inconsistency between optical fiber positions and preset conditions, so as to avoid unnecessary effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

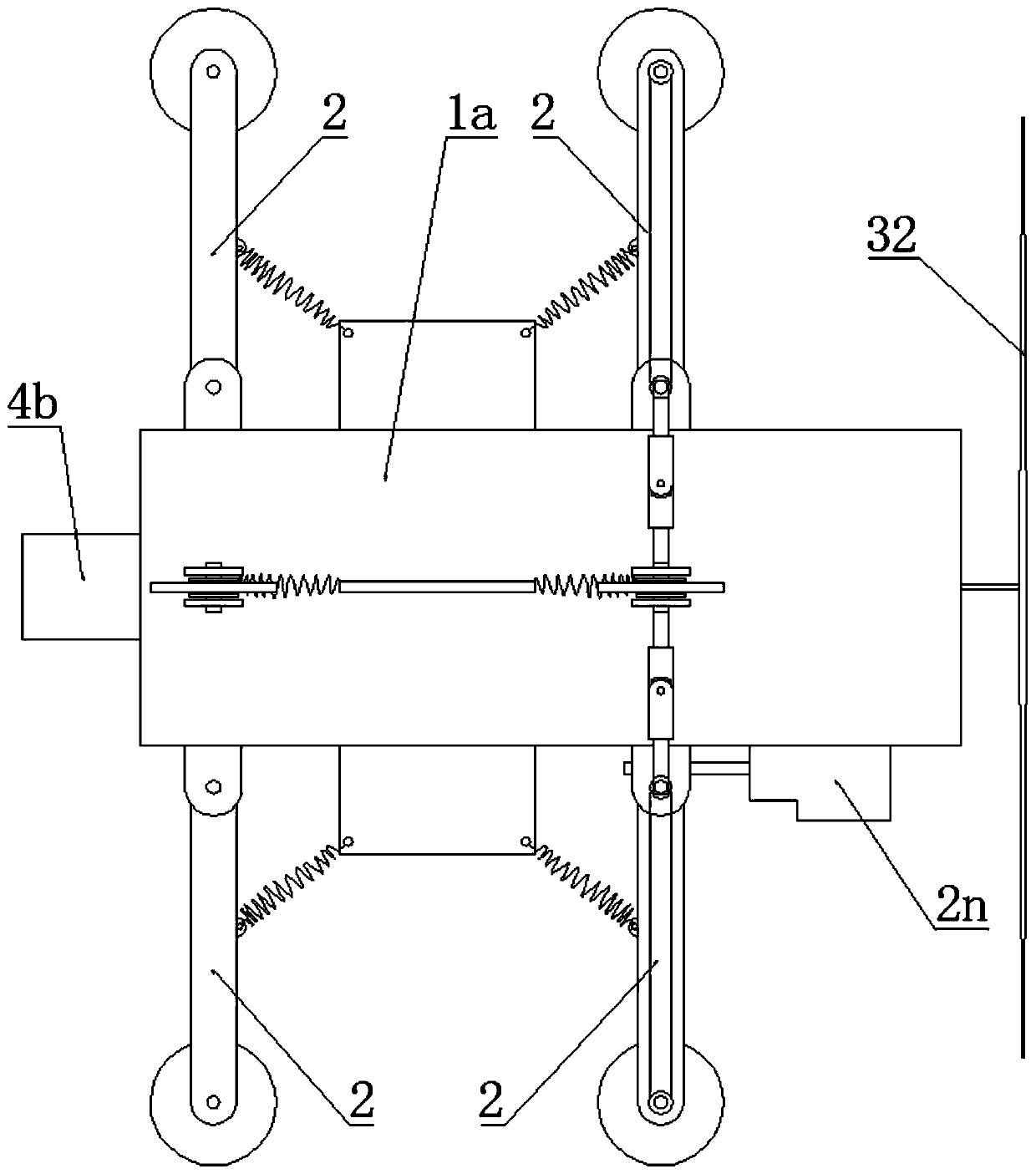

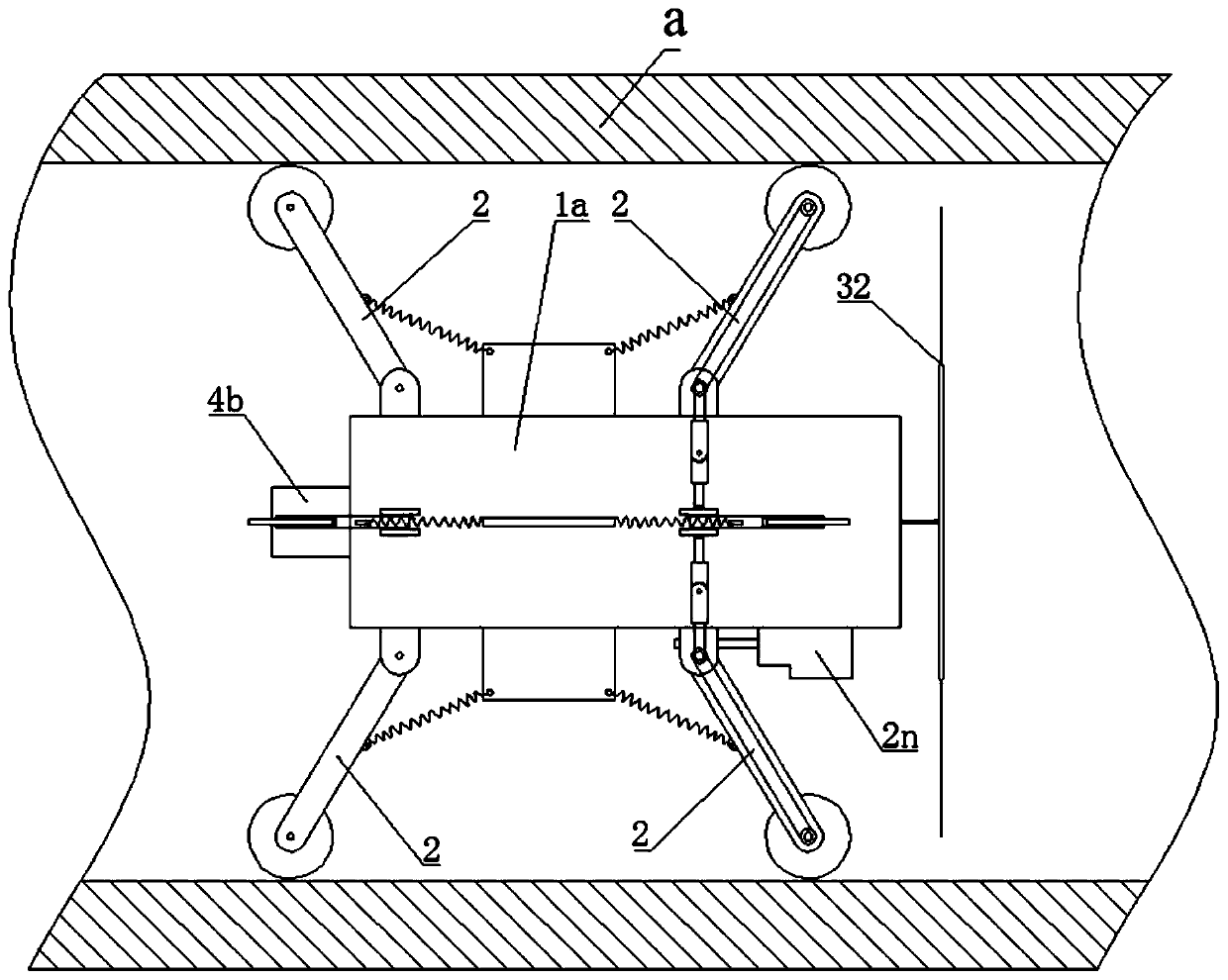

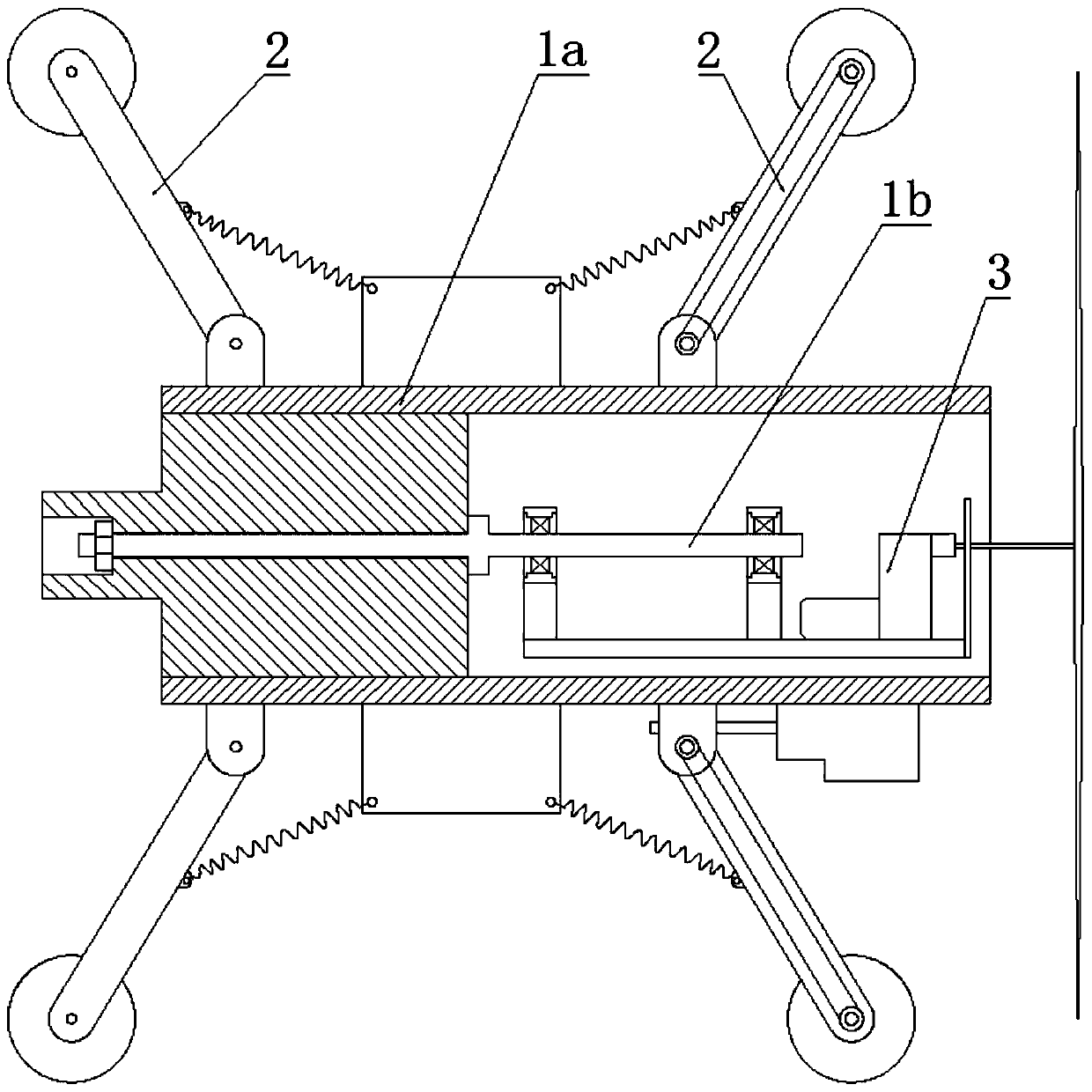

[0067] Such as Figure 1-7 As shown, a horizontal well downhole magnetic marker positioning device includes a horizontal support sleeve 1a, the outer wall of the support sleeve 1a is provided with a walking mechanism 2, and the support sleeve 1a is horizontally provided with a hoisting shaft 1b. A gravity eccentric assembly is movable on the shaft 1b, and a marking assembly 3 is arranged on the gravity eccentric assembly. Described seek assembly 3 comprises low-speed motor 31, and the output shaft of this low-speed motor 31 is arranged horizontally, and the output shaft of this low-speed motor 31 is fixedly connected with pointing magnetic needle 32, and the output shaft of described low-speed motor 31 and described pointing magnetic needle 32 mutually vertical.

[0068] The gravity eccentric assembly includes an eccentric weight plate 1c, the eccentric weight plate 1c is located below the hoisting shaft 1b, two lifting lugs 1d are fixed on the upper surface of the eccentric ...

Embodiment 2

[0087] A method for preventing the perforation damage of the optical cable of the horizontal well string is carried out according to the following steps:

[0088] Step 1, arranging the column a and the optical cable c;

[0089] Connect the pipe joints a1 with magnetic mark seats b on the outer wall in sequence along the same direction to form the pipe column a, the magnetic mark seats b are distributed at equal intervals on the pipe column a, and the optical cable c along the The length direction of the pipe string a is fixed on the magnetic mark base b, the optical cable c is lowered into the horizontal well synchronously with the pipe string a, and all magnetic poles of the same name of the magnetic mark base b face the pipe string a the pipe core line;

[0090] Step two, cementing;

[0091] Step 3: Detect and record the direction information of the downhole optical cable;

[0092] Such as figure 1 As shown, the positioning device d in the first embodiment is sent into t...

Embodiment 3

[0103] The difference with Embodiment 2 is that when determining the distribution diagram of the optical cable in step 3, such as Figure 10 , project the two adjacent magnetic marker seats b of A and B onto the same column section, in the figure, A' is obtained by projecting A onto the section where B is located, and an interposed between A' and B The central angle of is recorded as the angle θ of the cable area, and the area of the cylindrical surface between A and B corresponding to the angle θ of the cable area is recorded as the cable section f.

[0104] Such as Figure 11 , and then obtain the continuously distributed optical cable sections f according to the position information of the magnetic marker seat b, and combine all the optical cable sections f sequentially to obtain an optical cable area map.

[0105] The denser the above-mentioned magnetic marker seats b are arranged, the more accurate the optical cable area map drawn after detection will be.

[0106] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com