A shield machine propulsion method

A shield machine and shield technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of large labor and concrete volume, long maintenance period, low reuse rate, etc., and achieve the method of disassembly and installation. Simple, easy to transport, quick and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

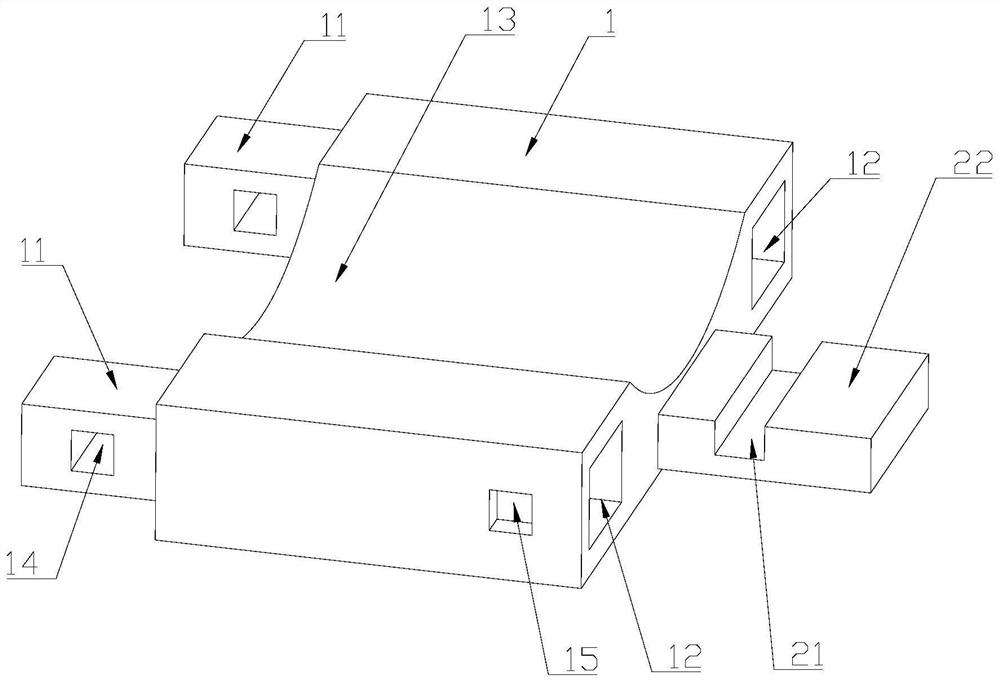

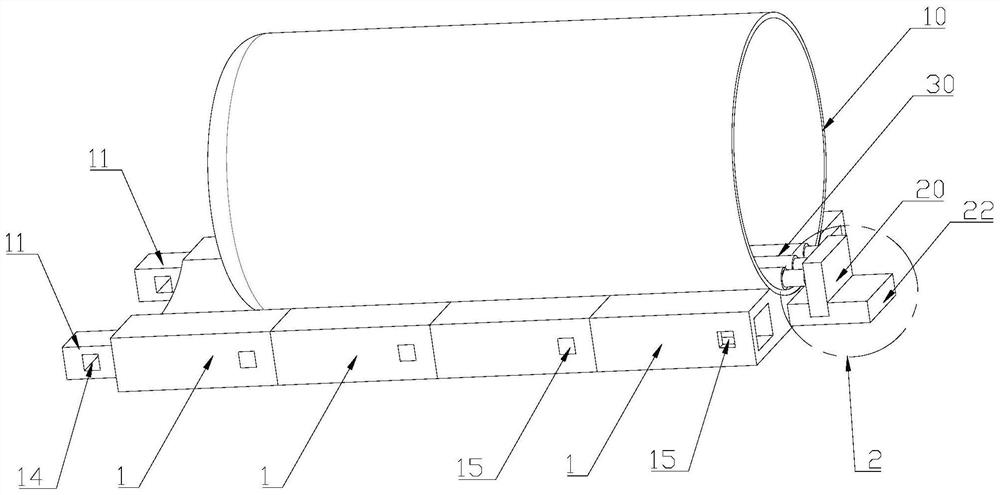

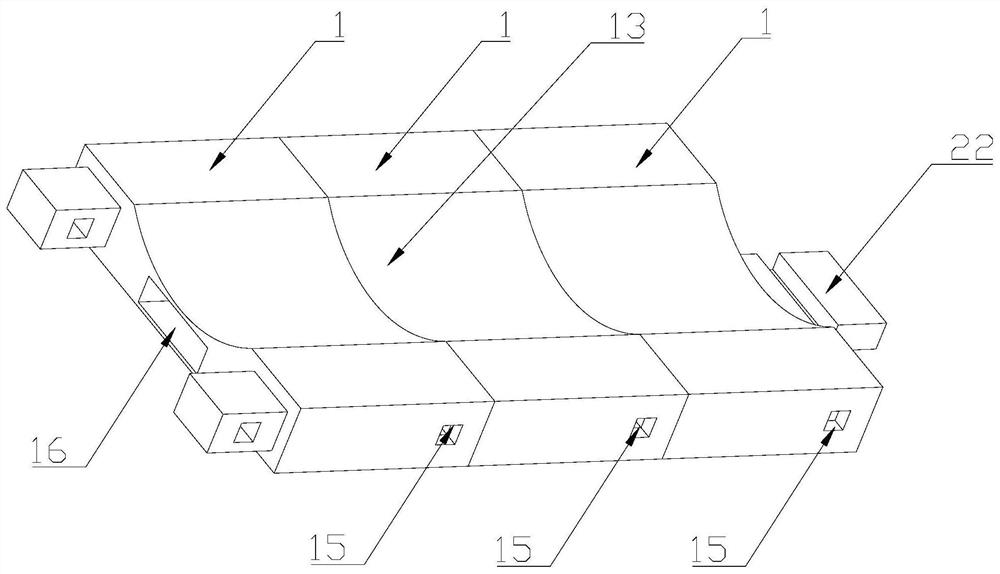

[0047] Such as figure 1 As shown, a propulsion device for a shield machine 10 includes at least two supports 1 that are detachably connected from head to tail, combined with figure 2 As shown, the shield machine 10 is placed on the support group, wherein the shield advancing direction is the head end, and the rear end of the support group is provided with a reaction force member 2 .

[0048] The support 1 is provided with a connecting part, and a detachable connection is realized between two adjacent supports 1 through the connecting part.

[0049] The supports 1 are nestedly connected to each other through the connecting parts.

[0050] One end of the support 1 is provided with a tenon 11 , and the other end is provided with a mortise 12 matching the tenon 11 , so as to realize the end-to-end connection of the support 1 . The middle part of the support 1 is provided with a groove 13 to prevent the shield machine 10 from rolling sideways.

[0051] The tenon 11 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com