Automatic tester for phase presented by prism

An automatic testing device and prism technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of narrow golden fingers, limited phase range, processing errors and other problems, and achieve economical and reasonable production costs and wide application range Broad, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] In conjunction with the accompanying drawings, the present invention is described in detail.

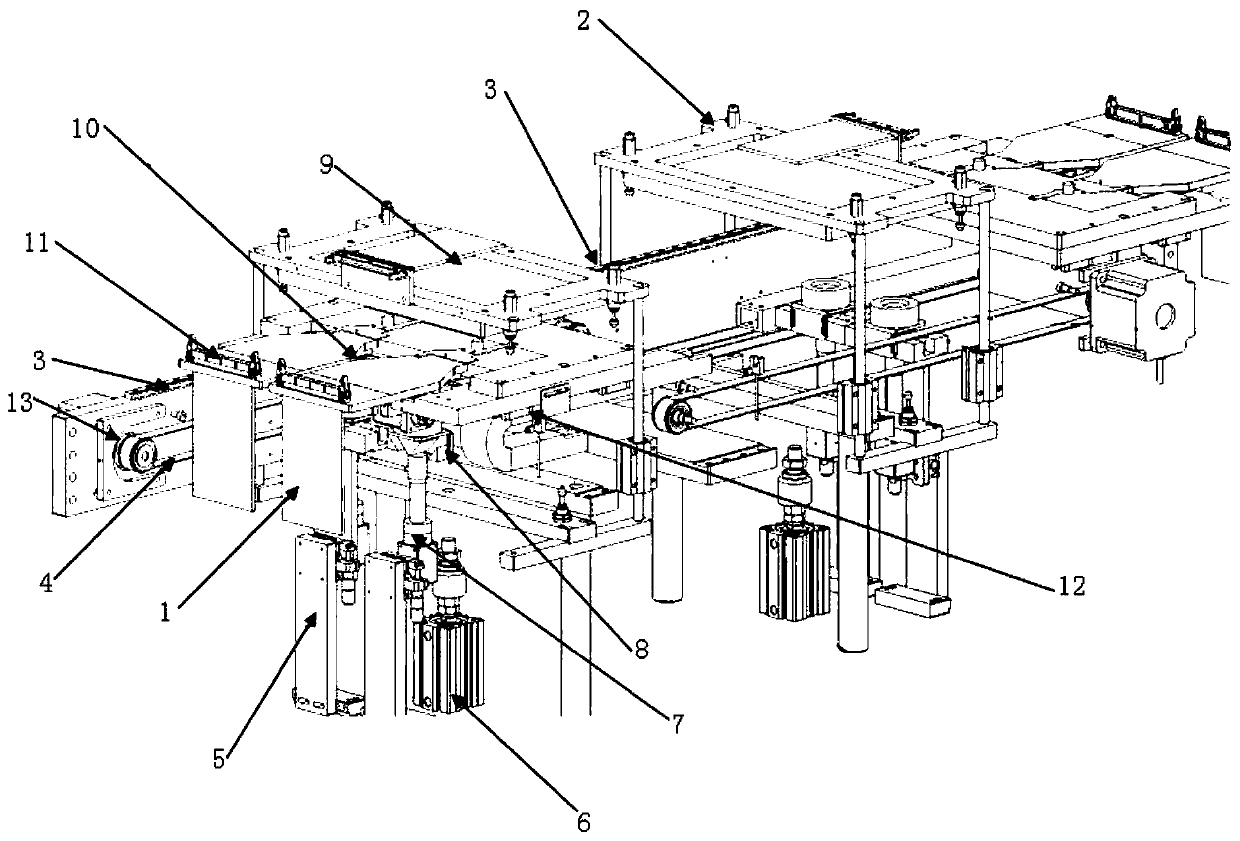

[0016] The present invention provides a kind of prism phase automatic testing device during concrete implementation, comprises the first belt-driven test platform 1 and the second belt-driven test platform 2, and the first belt-driven test platform 1 and the second belt-driven test platform 2 is provided with a guide rail 3 and a conveyor belt 4, the first belt-driven test platform 1 is connected with the second belt-driven test platform 2 through the guide rail 3 and the transmission belt 4, and the first belt-driven test platform 1 includes a bottom support frame 5 , pressing cylinder 6 and visual camera 7, described pressing cylinder 6 is arranged on the side of bottom support frame 5, and the top of described visual camera 7 is provided with prism combine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap