Hawthorn berry deep processing technology and production line thereof

A deep processing and production line technology, applied in the field of hawthorn deep processing technology and its production line, can solve the problems of low level of comprehensive processing and utilization technology, restricting the development of hawthorn industry, etc., and achieve the effect of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

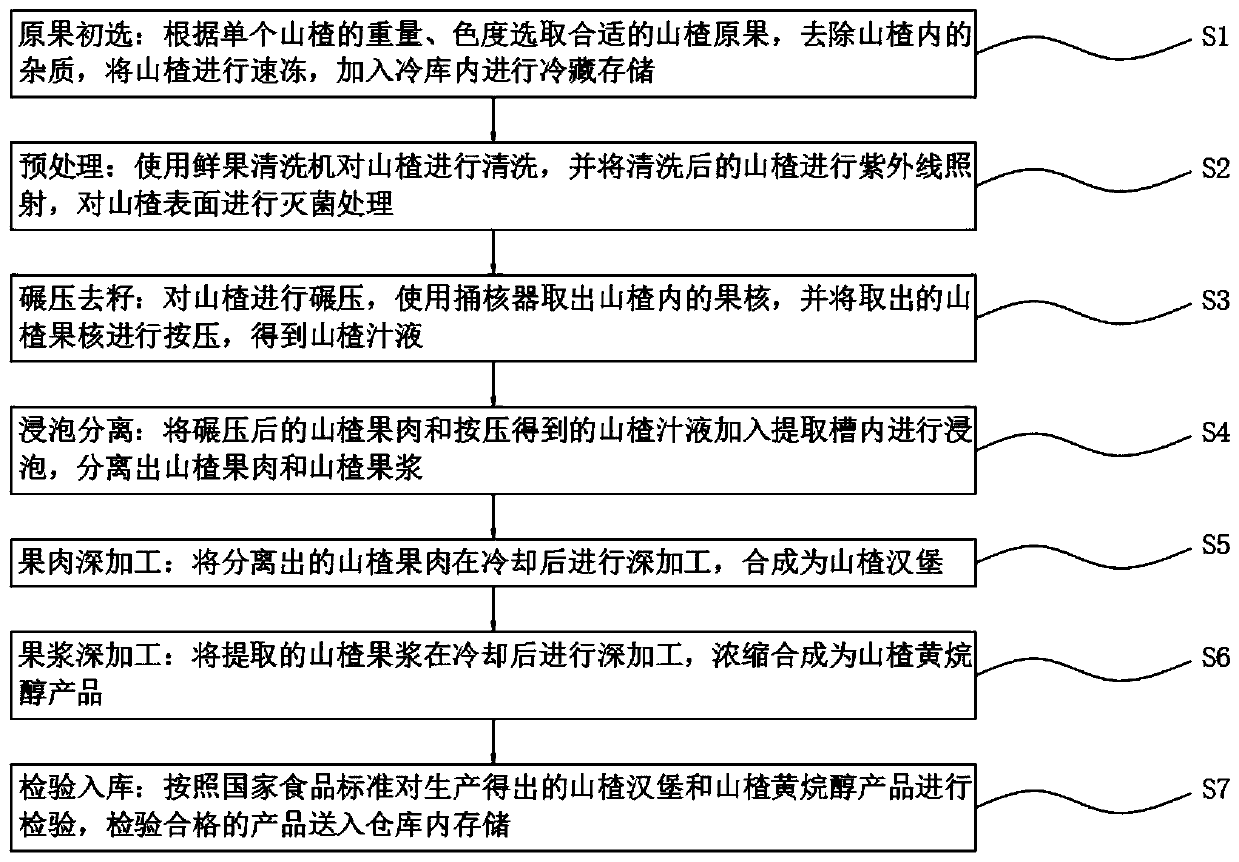

[0041] Embodiment 1: as figure 1 As shown, the present invention provides technical scheme, a kind of hawthorn deep processing technique, comprises the steps:

[0042] S1. Preliminary selection of original fruit: select the appropriate original fruit of hawthorn according to the weight and color of a single hawthorn, remove impurities in the hawthorn, quickly freeze the hawthorn, and put it into the cold storage for refrigerated storage;

[0043]S2. Pretreatment: use a fresh fruit cleaning machine to clean the hawthorn, and irradiate the cleaned hawthorn with ultraviolet rays to sterilize the surface of the hawthorn;

[0044] S3, rolling and removing seeds: rolling the hawthorn, using a poker to remove the core of the hawthorn, and pressing the removed hawthorn core to obtain the hawthorn juice;

[0045] S4. Soaking and separation: put the rolled hawthorn pulp and the pressed hawthorn juice into the extraction tank for soaking, and separate the hawthorn pulp and hawthorn pulp...

Embodiment 2

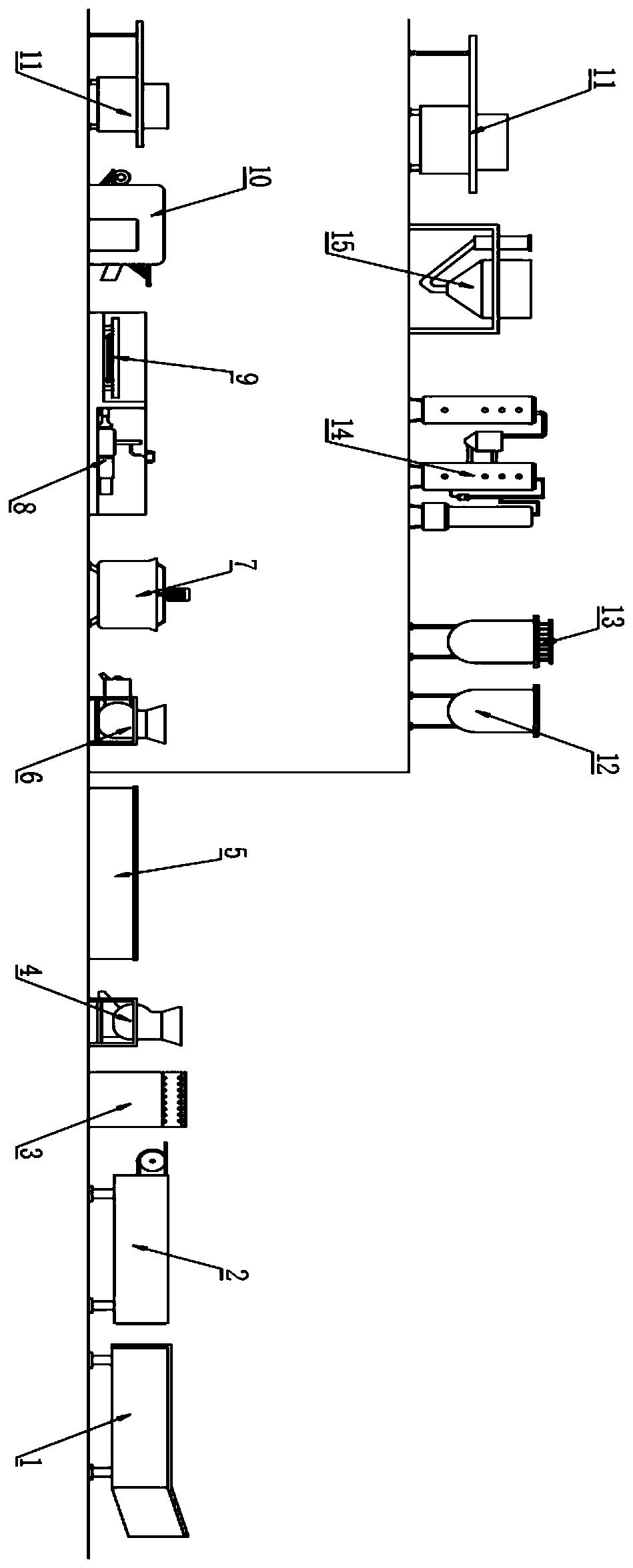

[0064] Embodiment 2: as figure 2 As shown, the present invention provides a technical solution, a hawthorn deep processing production line, comprising a fresh fruit cleaning machine 1, a side of the fresh fruit cleaning machine 1 is equipped with a pre-cooking machine 2 through a transmission belt, and one side of the pre-cooking machine 2 is provided with an ultraviolet disinfection cabinet 3 One side of the ultraviolet disinfection cabinet 3 is equipped with a crusher 4 through a transmission belt, one side of the crusher 4 is provided with an extraction tank 5, one side of the extraction tank 5 is provided with a beater 6, and one side of the beater 6 is provided with a mixer 7 , one side of the mixer 7 is provided with a homogenizer 8, one side of the end face of the homogenizer 8 is provided with an automatic scraper 9, one side of the automatic scraper 9 is provided with a roaster 10, and one part of the roaster 10 A packaging machine 11 is arranged on one side, and a h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap