Wheel speed sensor interface control circuit for active electronic brake system

A wheel speed sensor and electronic braking technology, which is applied in the direction of brakes, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of easy damage of wheel speed sensors, failure of component functions, troublesome replacement and installation, etc., to ensure safety and reliability performance, improve the service life, and protect the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, structure, features and functions of the present invention, the detailed description is as follows in conjunction with the embodiments.

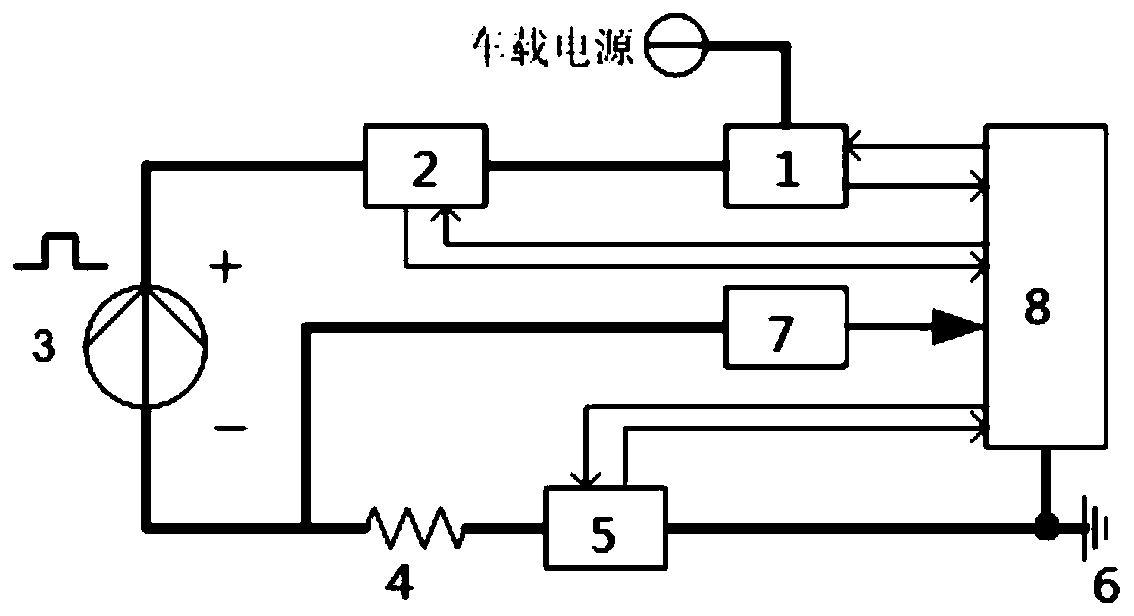

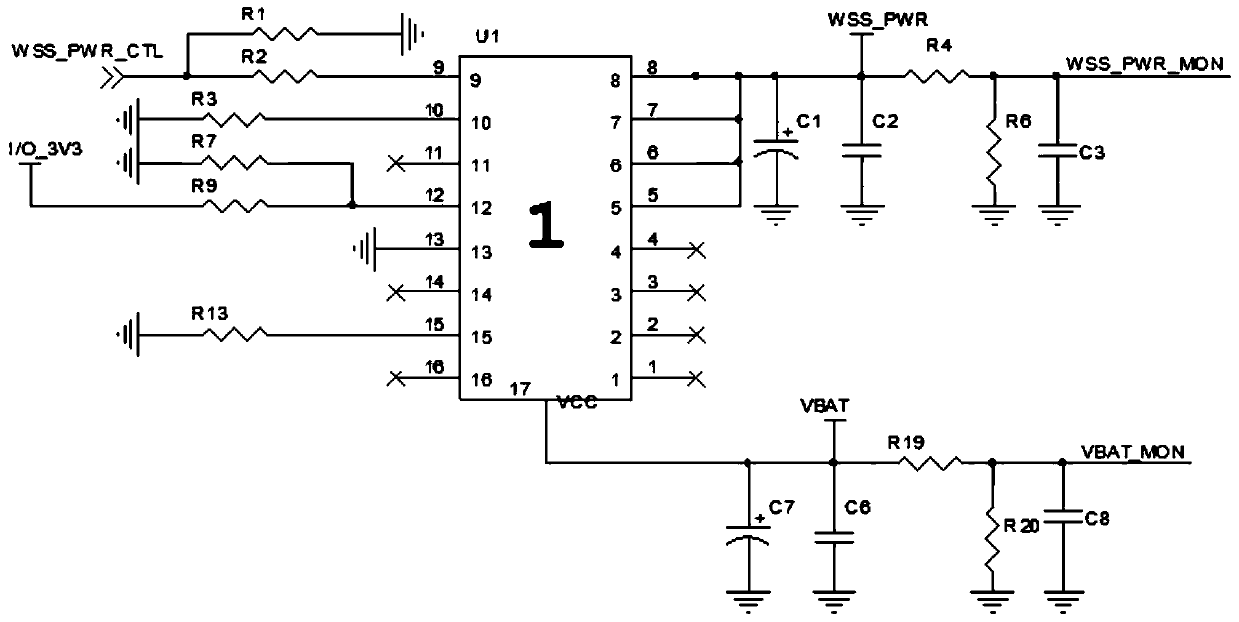

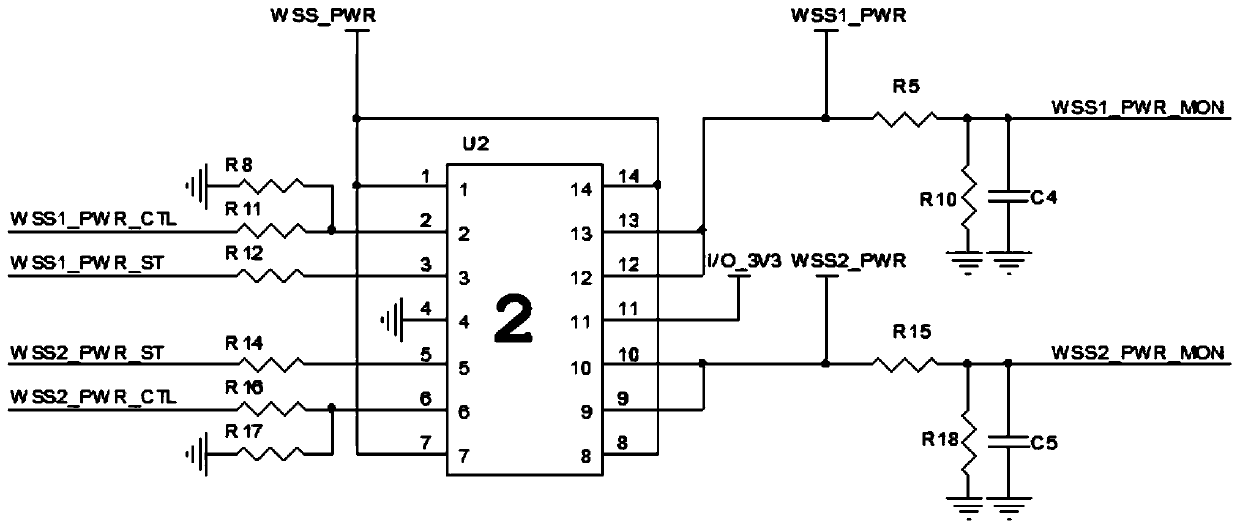

[0024] Such as Figure 1 to Figure 5 As shown, the wheel speed sensor interface control circuit used in the active electronic braking system of the present invention is used in conjunction with the wheel speed sensor 3. The wheel speed sensor 3 includes a positive terminal and a negative terminal, and the wheel speed sensor interface control circuit includes a power switch. Unit 1, high-side power supply unit 2, control unit 8, signal processing unit 7, resistor 4 and low-side power supply unit 5, power switch unit 1 is connected to the vehicle power supply, and high-side power supply unit 2 is respectively connected to the positive pole of the wheel speed sensor 3 The terminal and the power switch unit 1 are electrically connected, the signal processing unit 7 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com