Automatic film embedding machine

An automatic and film machine technology, applied in the directions of wrapping objects, packaging, transportation and packaging, etc., can solve the problems of finger pain, high work intensity, easy fatigue, etc., to reduce working time, reduce workload, and avoid finger pain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

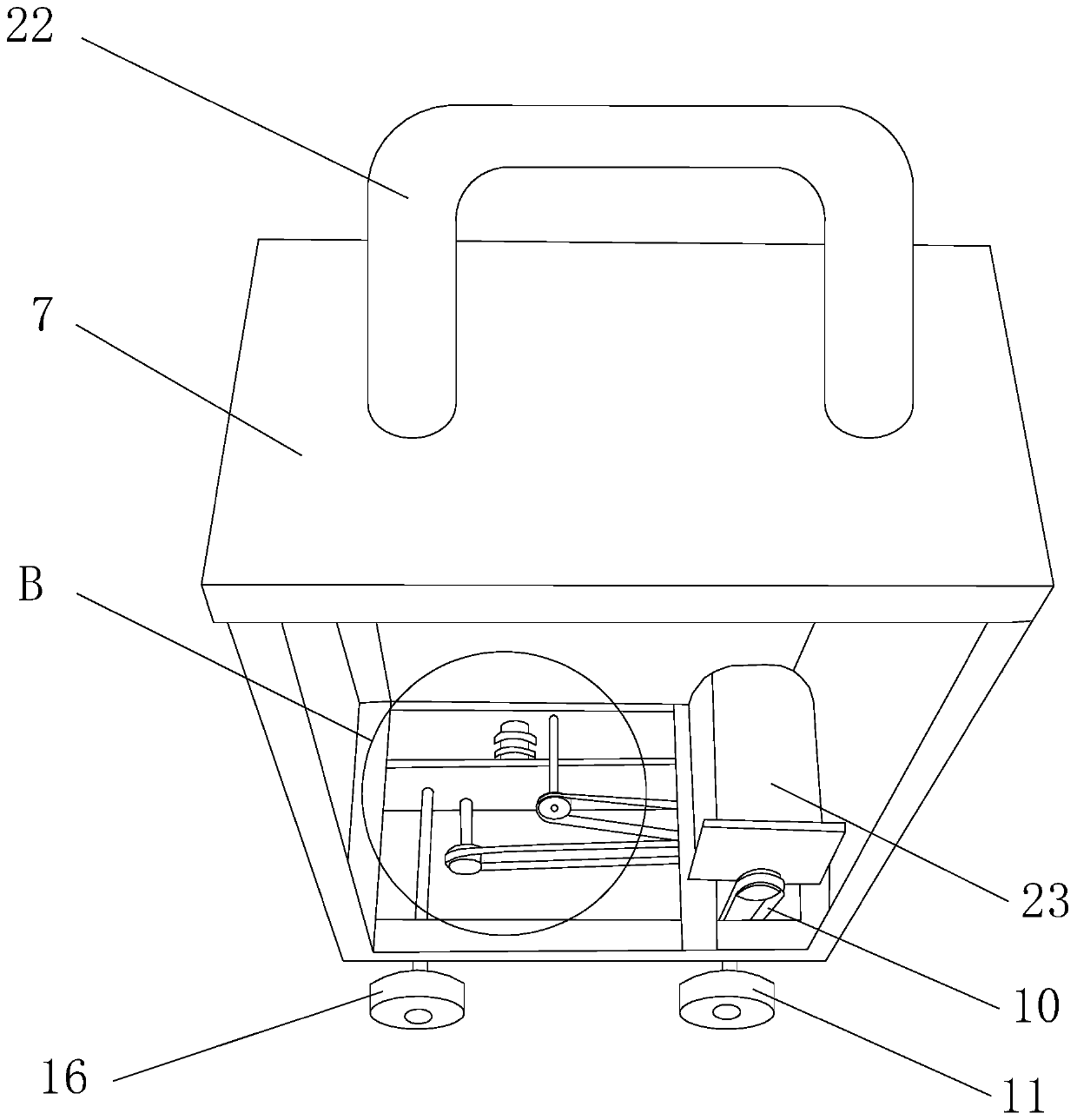

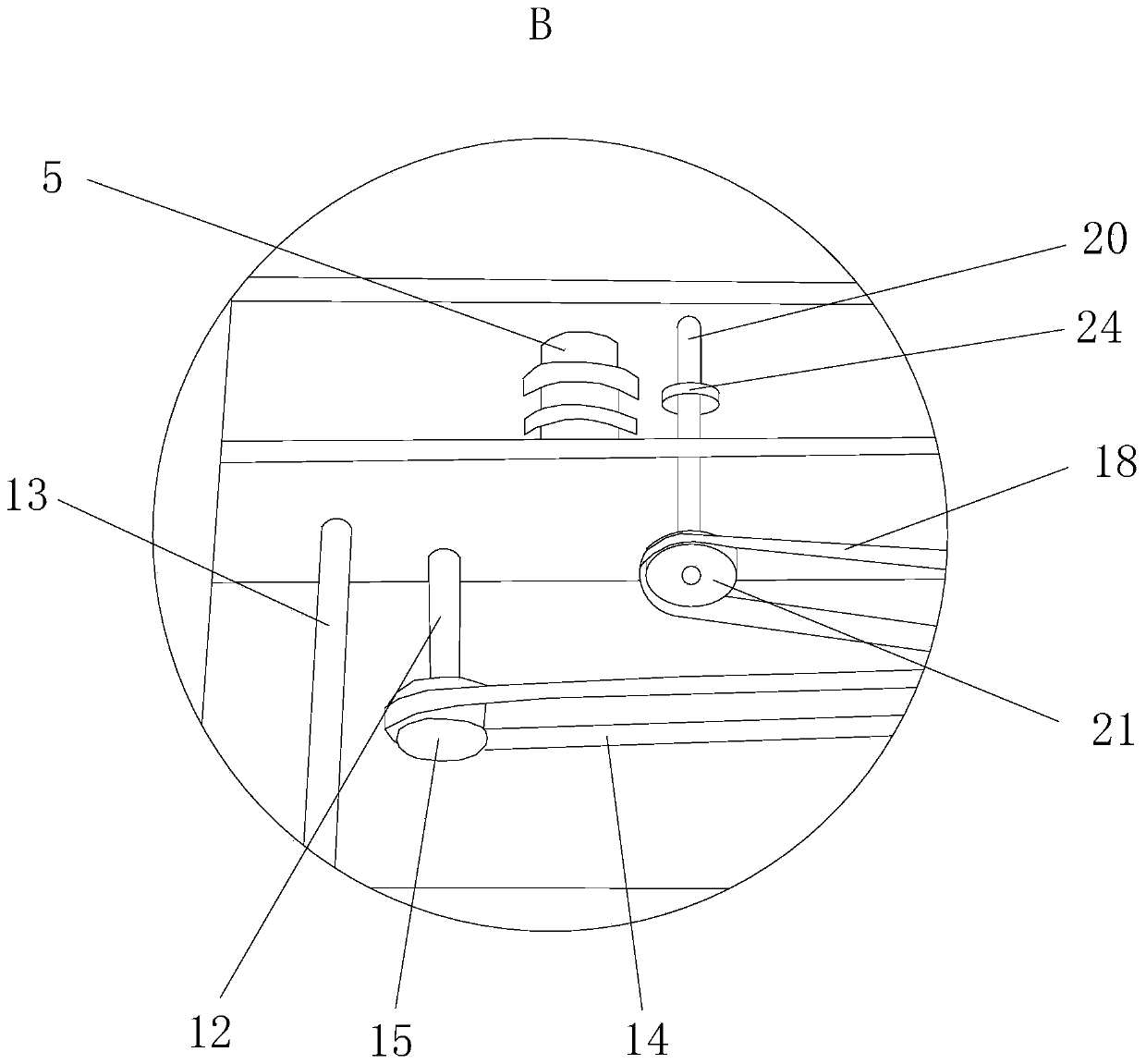

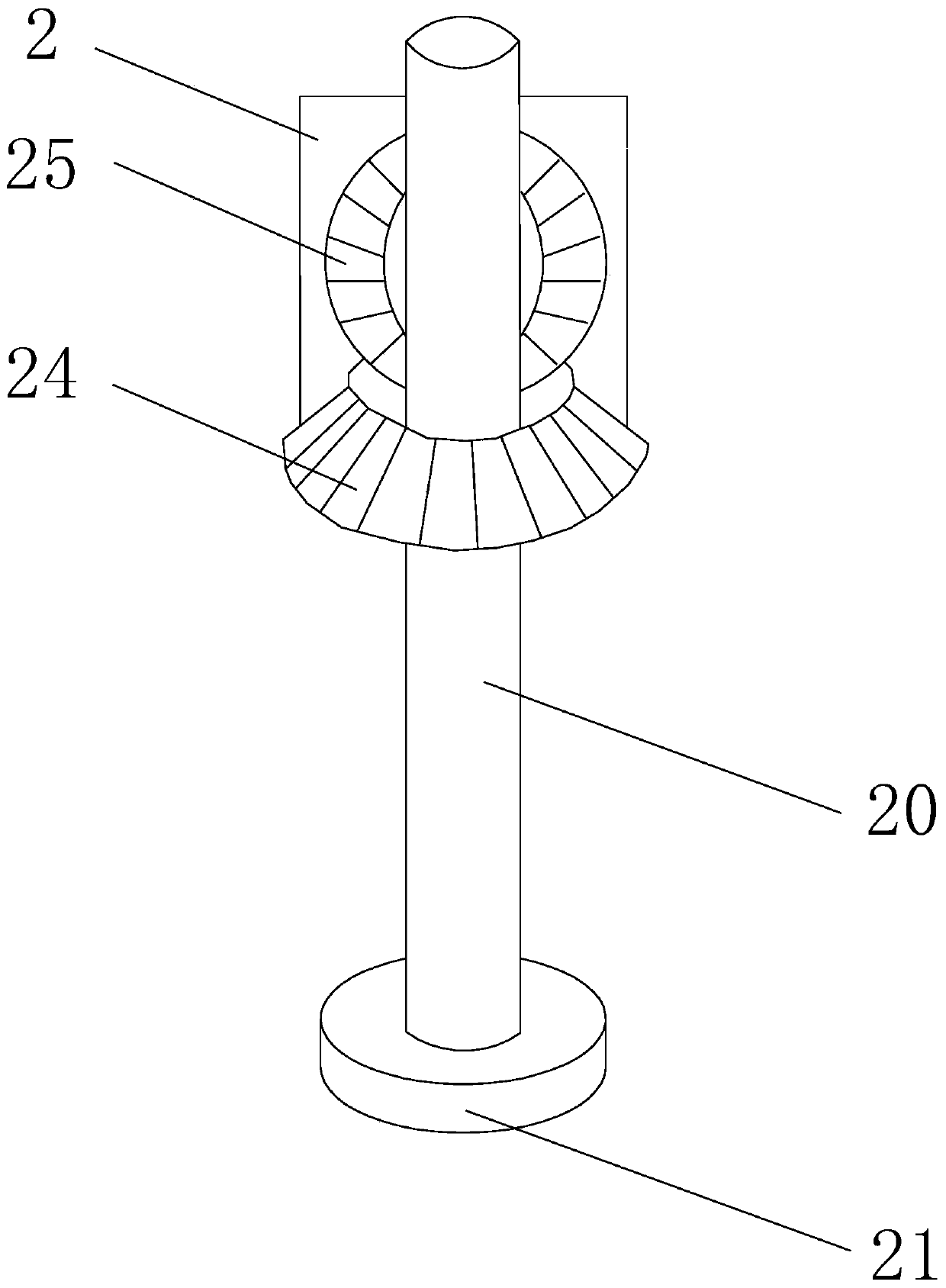

[0025] Automatic film embedding machine, such as Figure 1-6 As shown, it includes a casing 7, and the casing 7 is provided with a guide wheel 6, a first squeeze wheel 4, a second squeeze wheel 3 and a pinch wheel 1 from right to left, and the first squeeze wheel 4 and the second squeeze wheel The distance between the pressing wheels 3 is 6 mm, and the guide wheel 6 is provided with a convex ring 601 that presses the film sleeve 27 out of the groove marks. The first pressing wheel 4 and the second pressing wheel 3 are used to squeeze the rubber tube 26 In flat shape, the pressure roller 1 is provided with a groove 1011 for pressing the rubber tube 26 into the grooved tube 28 .

[0026] It also includes a motor 23 and a wheel shaft 8 . The first transmission pulley 10 is arranged on the wheel shaft 8 . The motor 23 is connected to the first transmission pulley 10 through the first transmission belt 9 .

[0027] The wheel shaft 8 is provided with a second drive pulley 17, the c...

Embodiment 2

[0036] Same as embodiment 1, the difference is that the distance between the first squeeze wheel 4 and the second squeeze wheel 3 is 2 mm, and the number of guide wheel 6 is one.

Embodiment 3

[0038] Same as embodiment 1, the difference is that the distance between the first extrusion wheel 4 and the second extrusion wheel 3 is 20 mm, and the number of guide wheels 6 is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com