Euipment for lifting municipal rain perforated strainer

A technology for extracting equipment and rain grates, which is applied in the direction of lifting devices and hoisting devices, can solve the problems of rain grate laboriousness, easy damage to rain grate, and easy injury, and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

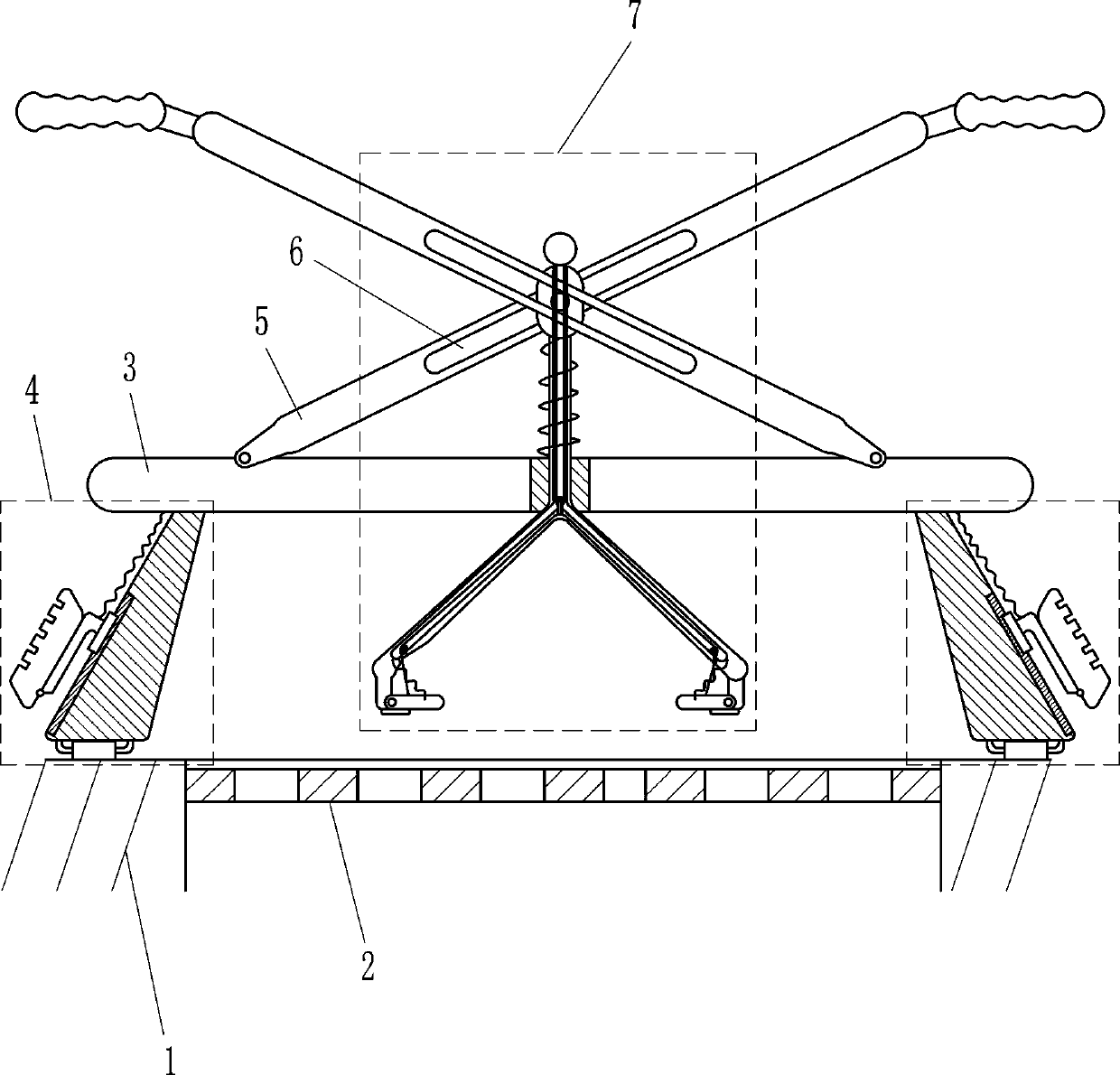

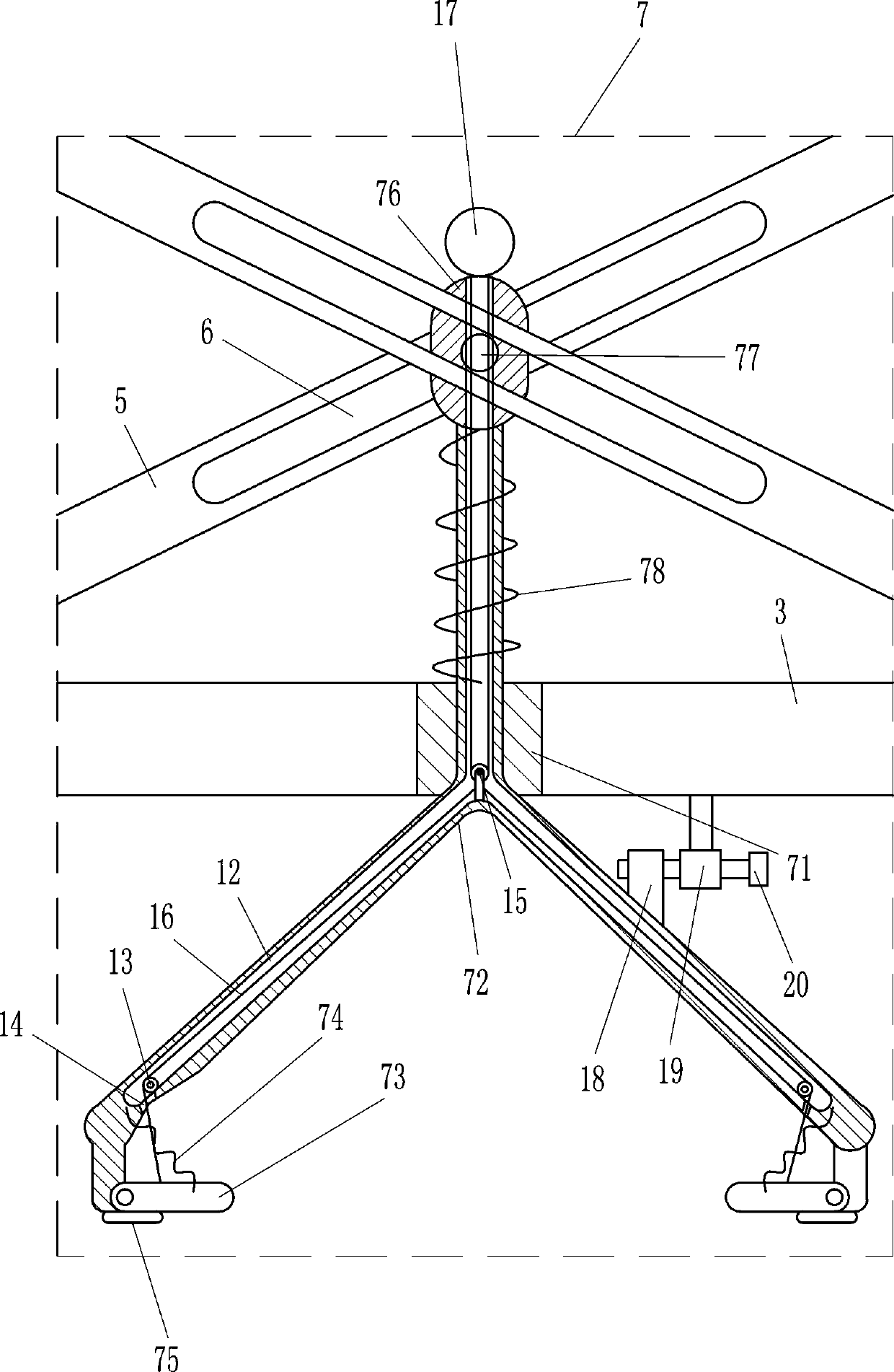

[0017] A municipal rain grate extraction equipment, such as Figure 1-3 As shown, it includes a connecting plate 3, a moving and fixing device 4, a swing rod 5 and a lifting device 7. The left and right sides of the bottom of the connecting plate 3 are equipped with a moving and fixing device 4, and the left and right parts on the upper side of the connecting plate 3 are hinged. A swing rod 5 is connected, and the middle parts of the two swing rods 5 are provided with a chute 6. The middle part of the connecting plate 3 is equipped with a lifting device 7. The swing rod 5 on the left side is hingedly connected with the upper part of the rear side of the lifting device 7. 5 is hingedly connected with the lifting device 7 front side upper part.

Embodiment 2

[0019] A municipal rain grate extraction equipment, such as Figure 1-3 As shown, it includes a connecting plate 3, a moving and fixing device 4, a swing rod 5 and a lifting device 7. The left and right sides of the bottom of the connecting plate 3 are equipped with a moving and fixing device 4, and the left and right parts on the upper side of the connecting plate 3 are hinged. A swing rod 5 is connected, and the middle parts of the two swing rods 5 are provided with a chute 6. The middle part of the connecting plate 3 is equipped with a lifting device 7. The swing rod 5 on the left side is hingedly connected with the upper part of the rear side of the lifting device 7. 5 is hingedly connected with the lifting device 7 front side upper part.

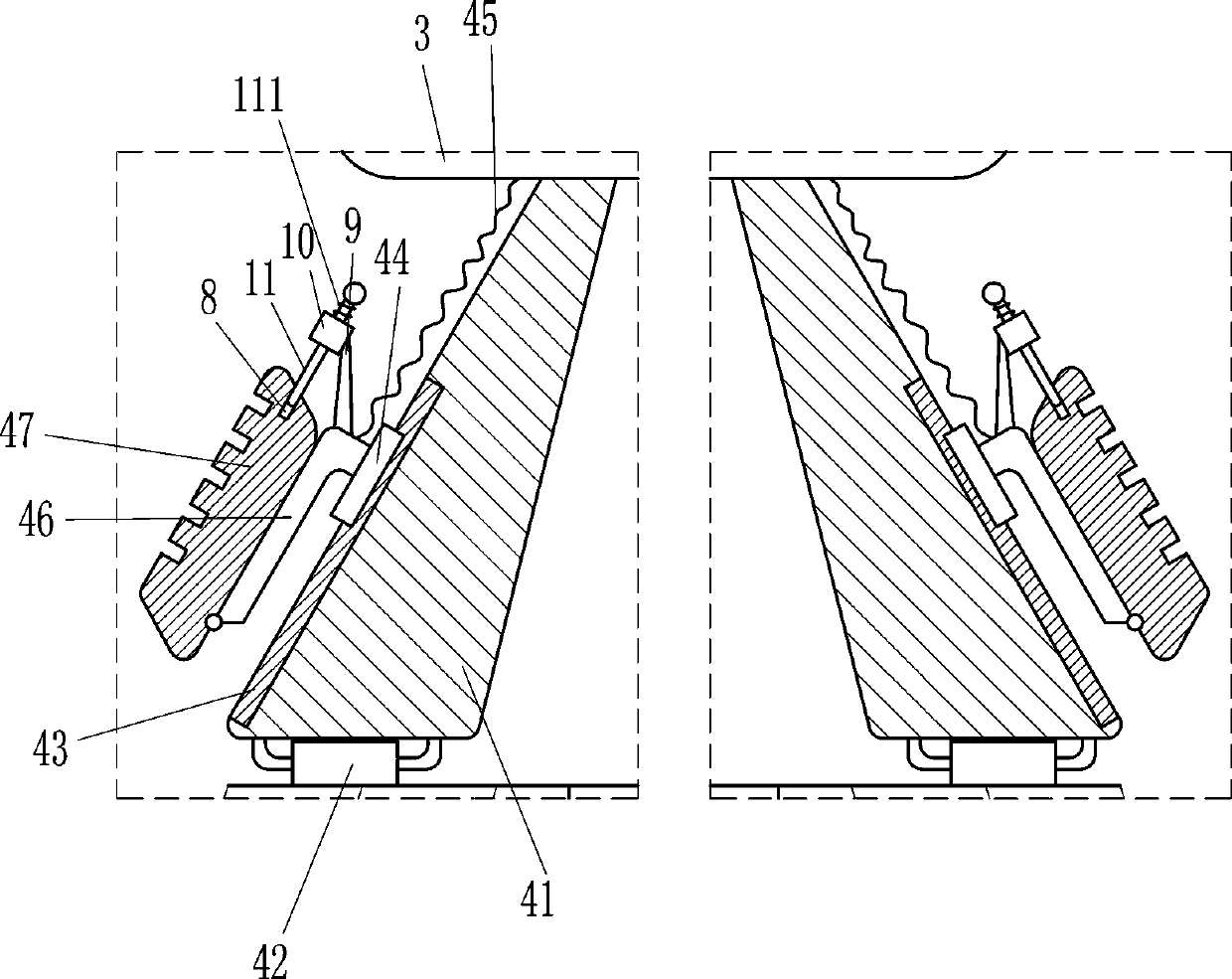

[0020] The moving and fixing device 4 includes a support plate 41, wheels 42, slide rails 43, slide block 44, first spring 45, L-shaped bar 46 and pedal 47, and the left and right sides of the connecting plate 3 are connected with a sup...

Embodiment 3

[0022] A municipal rain grate extraction equipment, such as Figure 1-3 As shown, it includes a connecting plate 3, a moving and fixing device 4, a swing rod 5 and a lifting device 7. The left and right sides of the bottom of the connecting plate 3 are equipped with a moving and fixing device 4, and the left and right parts on the upper side of the connecting plate 3 are hinged. A swing rod 5 is connected, and the middle parts of the two swing rods 5 are provided with a chute 6. The middle part of the connecting plate 3 is equipped with a lifting device 7. The swing rod 5 on the left side is hingedly connected with the upper part of the rear side of the lifting device 7. 5 is hingedly connected with the lifting device 7 front side upper part.

[0023] The moving and fixing device 4 includes a support plate 41, wheels 42, slide rails 43, slide block 44, first spring 45, L-shaped bar 46 and pedal 47, and the left and right sides of the connecting plate 3 are connected with a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com